Mitsubishi Colt Ralliart. Manual - part 607

ROCKER ARMS AND CAMSHAFT

ENGINE OVERHAUL <4G1>

11D-28

REMOVAL SERVICE POINTS

<<A>> CAM POSITION SENSING CYLIN-

DER REMOVAL

AK201784

Holding the hexagonal portion of the camshaft with a

wrench, remove the cam position sensing cylinder.

<<B>> LASH ADJUSTER REMOVAL

CAUTION

If the lash adjuster is to be reused, be sure to

clean and inspect it before installation. (Refer

to

INSTALLATION SERVICE POINTS

>>A<< LASH ADJUSTER INSTALLATION

CAUTION

If the lash adjuster is to be reused, be sure to

clean and inspect it before installation. (Refer

to

While using care not to spill diesel fuel in the lash

adjuster, install the lash adjuster on the rocker arm.

>>B<< CAMSHAFT INSTALLATION

AK201833 AC

Timing belt side

Journal

Cam

Slit

CAUTION

• Do not confuse intake and exhaust cam-

shafts.

• A 4 mm slit is on the rear end of the intake

camshaft.

Apply engine oil to the camshaft journal and cams

before installation.

>>C<< FRONT BEARING CAP/BEARING

CAP/REAR RIGHT BERING CAP/REAR

LEFT BEARING CAP INSTALLATION

AK201834AC

Dowel pin

1. Place the dowel pins of the camshafts in the

positions shown in the illustration.

NOTE: By getting the dowel pins into position

shown in the illustration, the camshaft slots of

tightening the cylinder head bolt are put in posi-

tion.

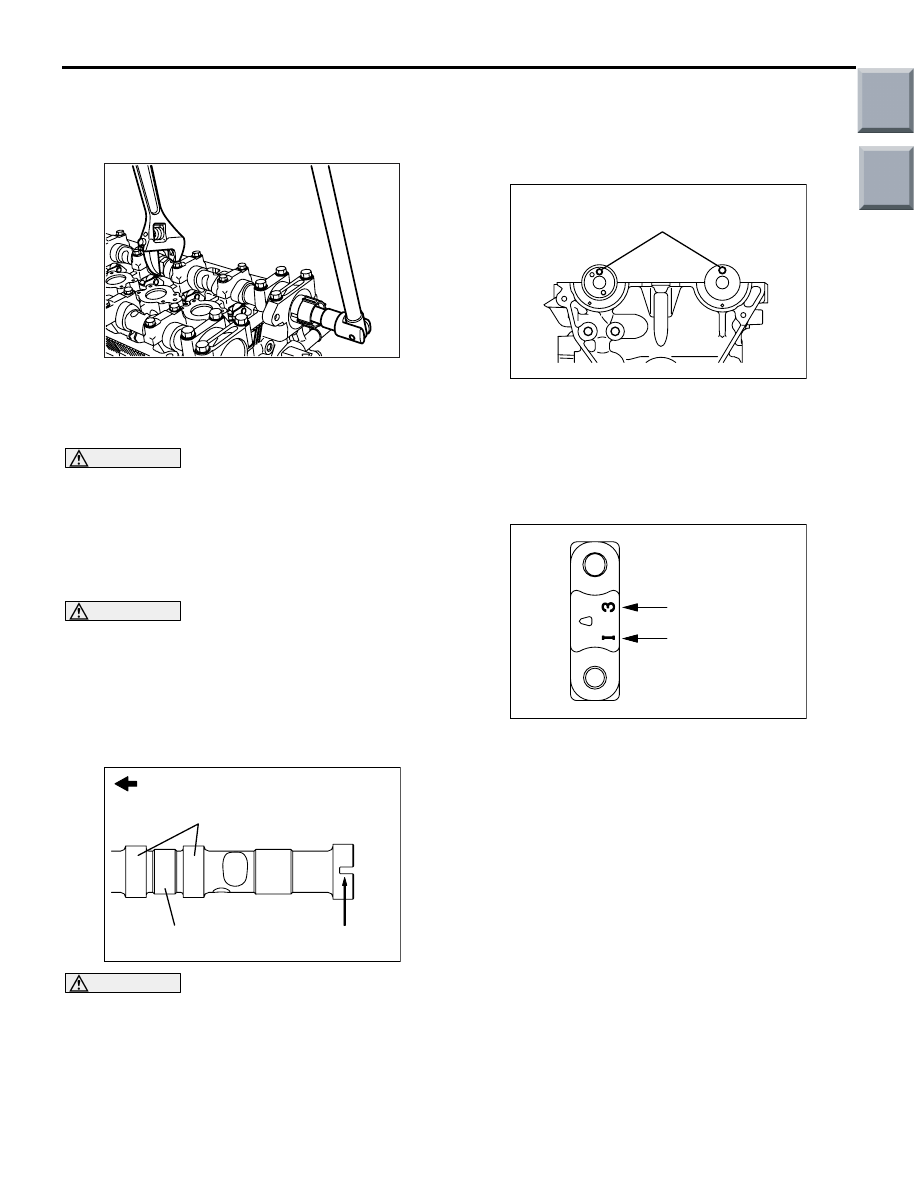

AK201835AC

Cap No.

Identification mark

for intake/exhaust side

2. The bearing caps No. 2 to 5 are identical in shape.

Before installation, be sure to check the cap

numbers and identification marks so that right

bearing caps are installed in right places.

Identification marks (Die-stamped on front

and No. 2 to 5 bearing caps)

I: Intake side

E: Exhaust side

3. Completely remove existing sealant from the

bearing caps and cylinder head.

Main

Index

Group

TOC