Mitsubishi Colt Ralliart. Manual - part 603

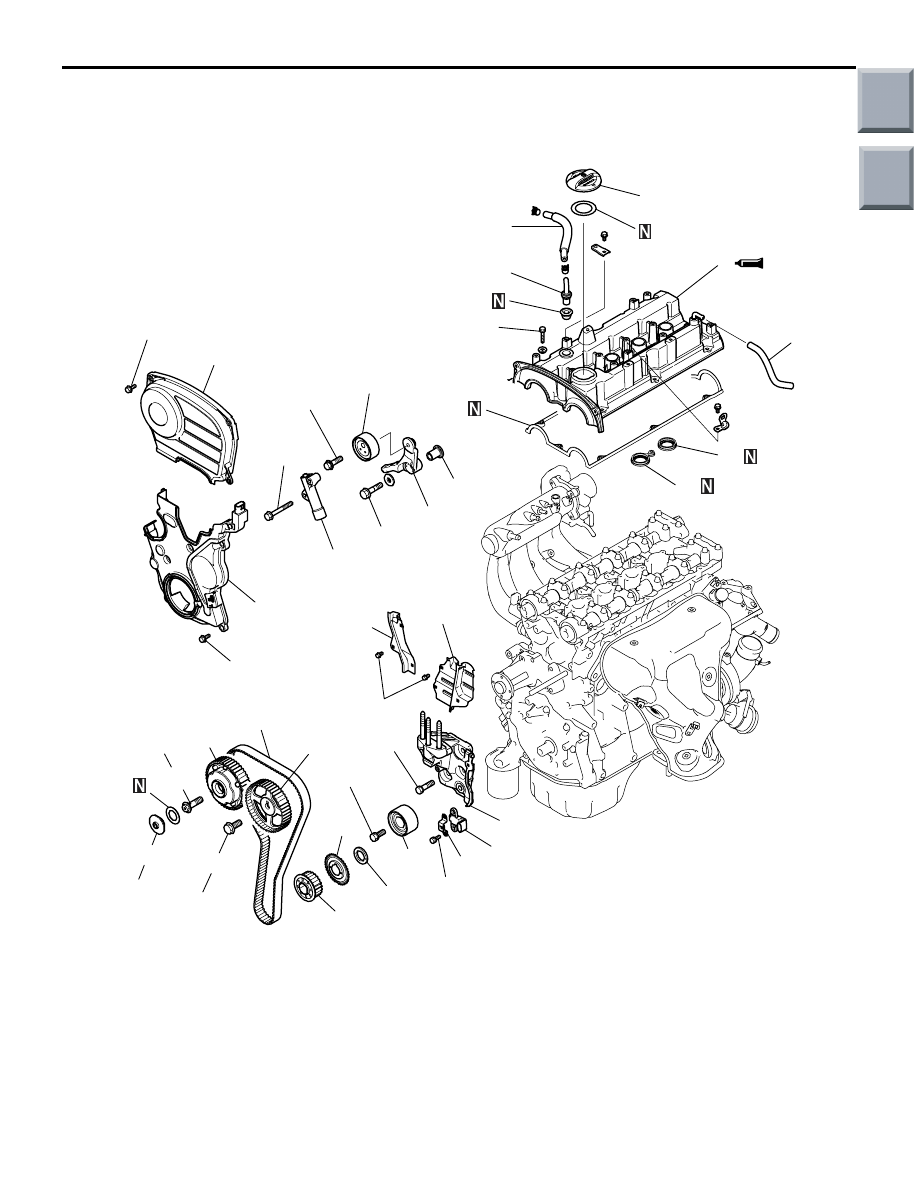

TIMING BELT

ENGINE OVERHAUL <4G1>

11D-12

TIMING BELT

REMOVAL AND INSTALLATION

M1113001901387

AK600556AC

1

11 ± 1 N·m

11 ± 1 N·m

2

7

6

5

4

3

24

12

9

10

11

8

14

16

15

17

28

20

18

23

21

27

13

25

30

29

36 ± 6 N·m

44 ± 10 N·m

21 ± 3 N·m

88 ± 10 N·m

22

9.8 ± 2.0 N·m

48 ± 6 N·m

48 ± 6 N·m

23 ± 3 N·m

55 ± 5 N·m

11 ± 1 N·m

19

26

5.0 ± 1.0 N·m

→ 7.0 ± 1.0 N·m

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Breather hose

4. PCV hose

5. PCV valve

6. PCV valve gasket

7. Oil filler cap

>>

H

<< 8. Rocker cover

9. Rocker cover gasket A

10. Rocker cover gasket B

11. Rocker cover gasket C

<<

A

>> >>

G

<< 12. Plug cap

<<

B

>> >>

F

<< 13. Timing belt

>>

E

<< 14. Tensioner pulley

15. Tensioner arm

16. Shaft

>>

D

<< 17. Auto-tensioner

18. Idler pulley

19. Bracket

20. Crank angle sensor

Removal steps (Continued)

Main

Index

Group

TOC