Mitsubishi Colt Ralliart. Manual - part 601

REWORK DIMENSIONS

ENGINE OVERHAUL <4G1>

11D-4

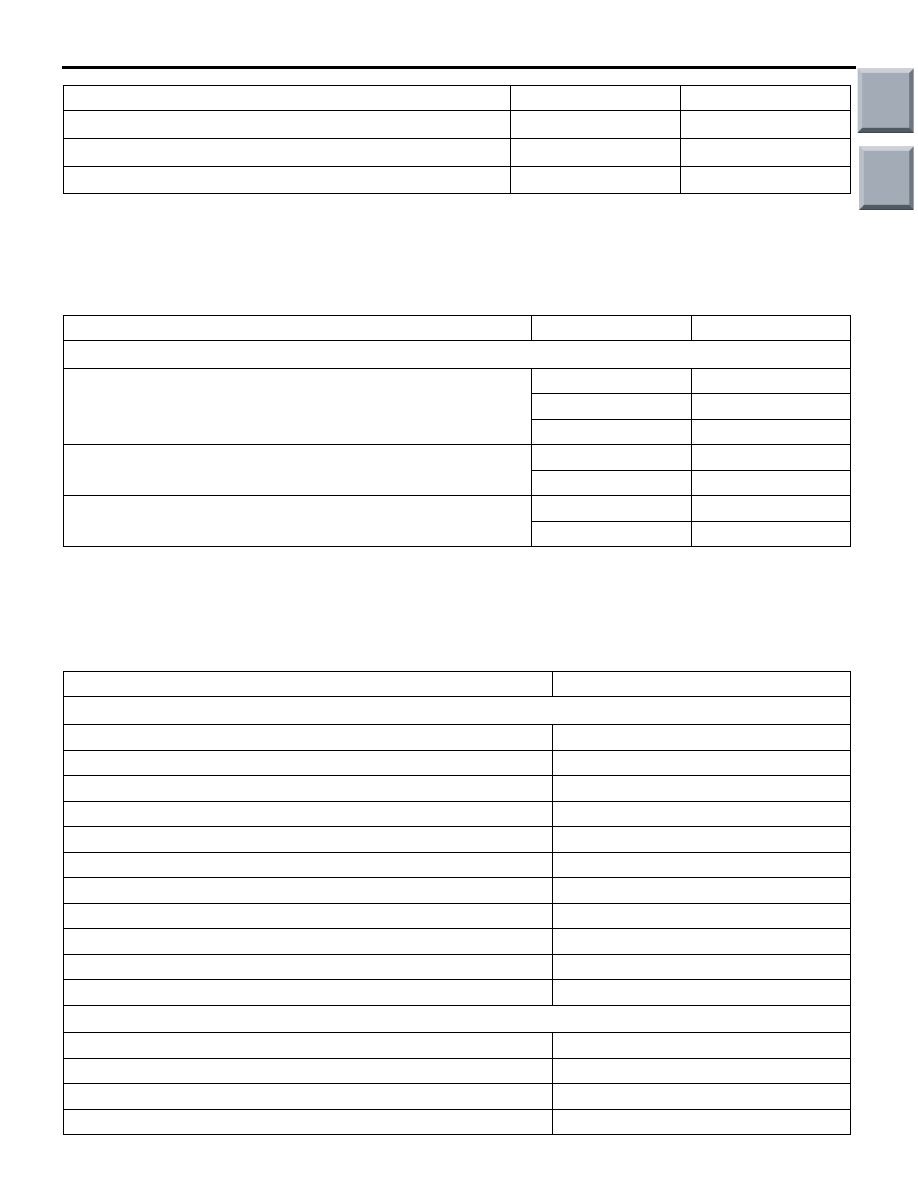

REWORK DIMENSIONS

M1113024300480

Item

Standard value

Standard value

CYLINDER HEAD AND VALVES

Cylinder head oversize valve guide hole diameter mm

0.05 O.S.

10.55

− 10.57

0.25 O.S.

10.75

− 10.77

0.50 O.S.

11.00

− 11.02

Cylinder head oversize valve seat hole diameter, intake mm

0.30 O.S.

31.30

− 31.33

0.60 O.S.

31.60

− 31.63

Cylinder head oversize valve seat hole diameter, exhaust mm

0.30 O.S.

27.80

− 27.82

0.60 O.S.

28.10

− 28.12

TORQUE SPECIFICATIONS

M1113023401777

Cylinder bore diameter mm

75.50

− 75.53

−

Taper of cylinder mm

0.01 or less

−

Cylinder-to-piston clearance mm

0.02

− 0.04

−

Item

Standard value

Limit

Item

N

⋅m

ALTERNATOR AND IGNITION SYSTEM

Oil level gauge guide bolt

24

± 4

Water pump pulley bolts

9.0

± 2.0

Crankshaft bolts

181

Alternator brace bolt (alternator side)

22.5

± 2.5

Alternator brace bolt (tightened with water pump)

24

± 3

Alternator nut

44

± 10

Adjusting bolt

5.0

± 1.0

Ignition coil bolts

10

± 2

Spark plug

25

± 5

Cam position sensor bolt

8.8

± 1.0

Cam position sensor support bolts

14

± 1

TIMING BELT

Timing belt cover bolts

11

± 1

Rocker cover bolts

5.0

± 1.0 → 7.0 ± 1.0

Plug cap

21

± 3

Tensioner pulley bolt

48

± 6

Main

Index

Group

TOC