Mitsubishi Colt Ralliart. Manual - part 269

PISTON AND CONNECTING ROD

ENGINE OVERHAUL <4A9>

11B-40

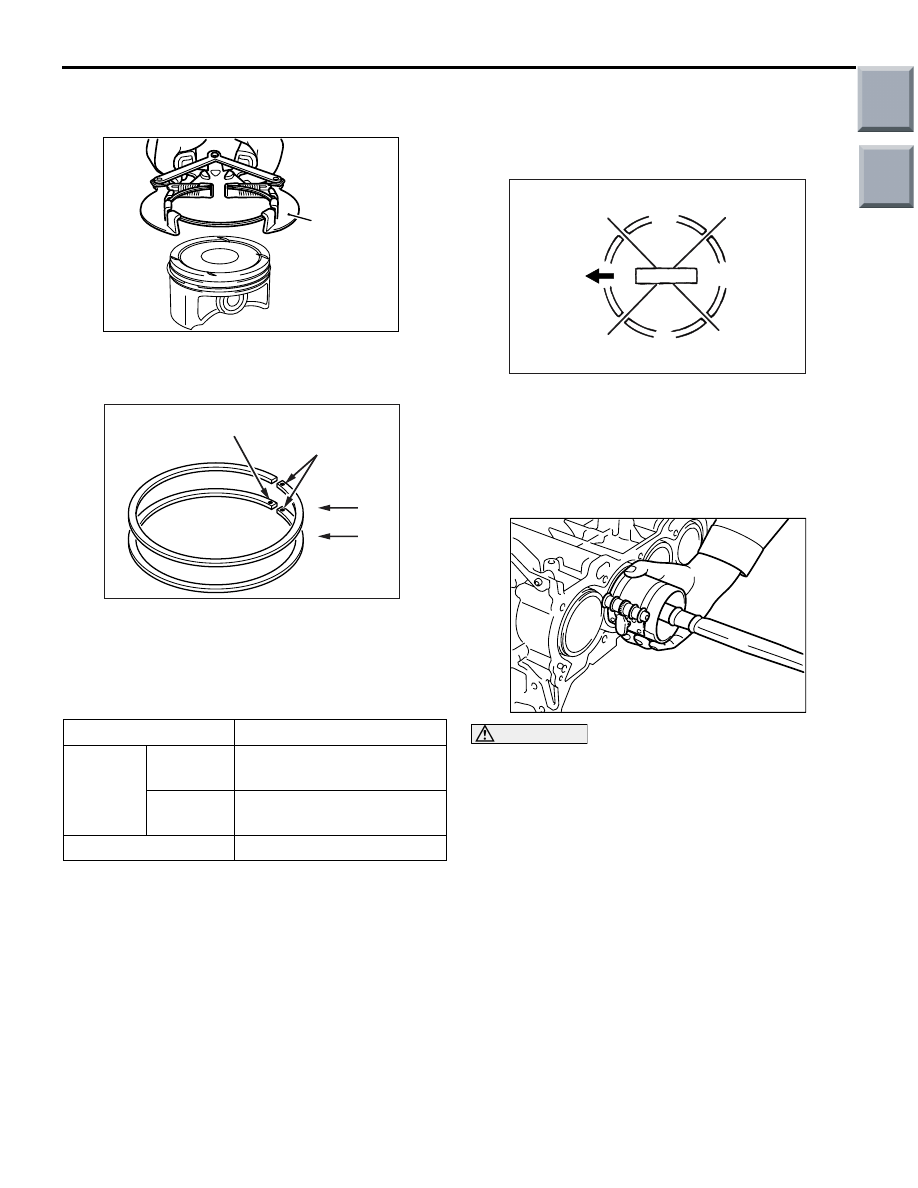

>>C<< PISTON RING NO. 2 / PISTON

RING NO. 1 INSTALLATION

AK304892AB

Piston ring

expander

Use a piston ring expander to install the No. 1 and

No. 2 piston rings. The ring identification mark should

face upwards.

AK402172

No. 2

AC

No. 1

Size marks

Identification mark

Identification mark

No. 1 ring: None

No. 2 ring: 2R

NOTE: Each of the available piston rings has a size

mark as follows:

Size

Size mark

Standard No. 1 ring No mark

(Yellow paint on periphery)

No. 2 ring No mark

(Yellow paint on periphery)

0.25 mm oversize

25

>>D<< PISTON, CONNECTING ROD

ASSEMBLY INSTALLATION

1. Apply engine oil sufficiently onto the piston

periphery, the piston rings and the oil ring.

AK202730

No. 1

No. 2

Side rail

Side rail

AC

Piston pin

2. Align the gaps of the piston rings and the oil ring

(side rails, spacer) as illustrated.

3. Insert the piston and connecting rod assembly

from above the cylinder block and through the

cylinder bore, ensuring that the front mark on the

piston top faces the camshaft sprocket.

AK304957

CAUTION

Do not try to strike hard on the assembly to fit it

in place as this will break the piston rings.

4. While firmly holding the piston rings with a ring

band, insert the piston and connecting rod

assembly into place.

Main

Index

Group

TOC