Mitsubishi Colt Ralliart. Manual - part 218

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-18

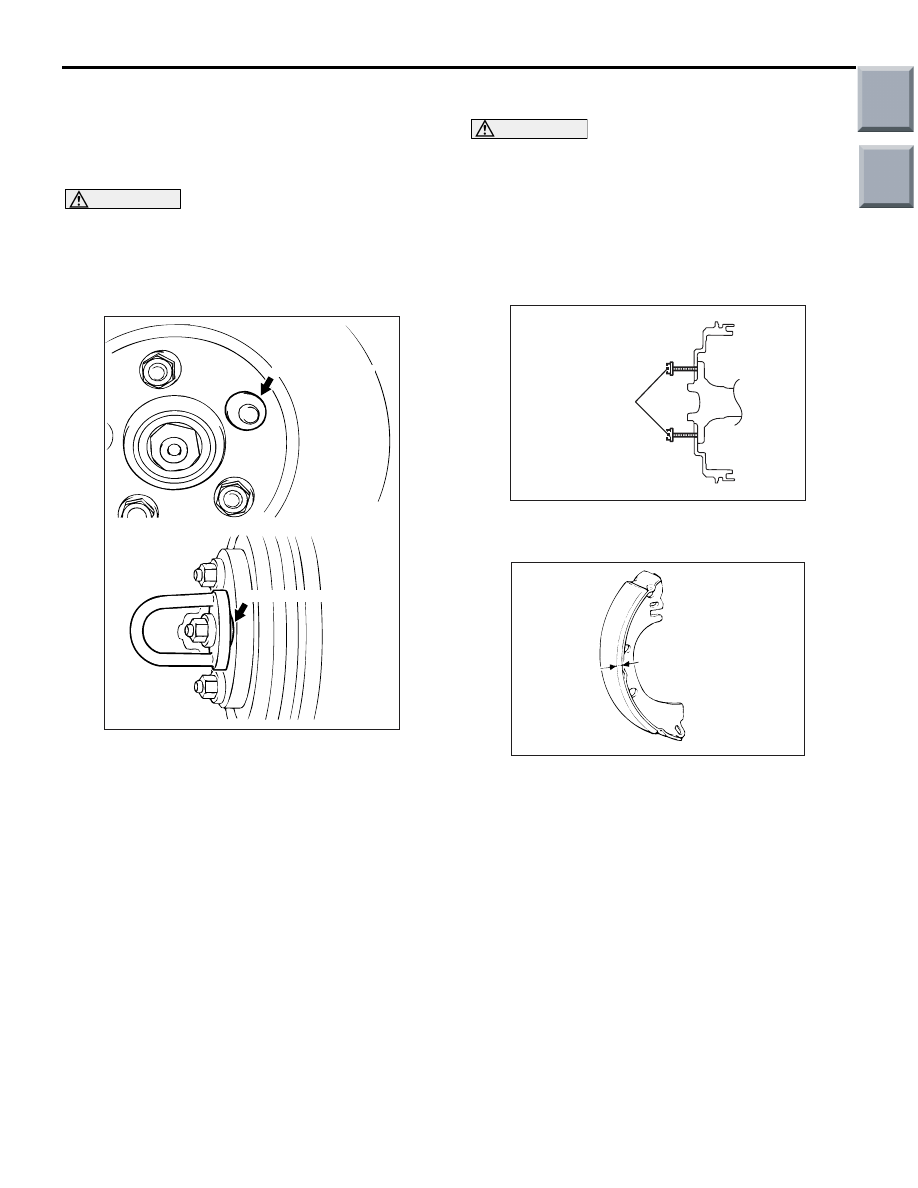

(3) If the axial play exceeds the limit, disassemble

the hub assembly to check each part.

(4) If the axial play does not exceed the limit,

dephase the brake disc and secure it. Then

recheck the brake disc run-out.

CAUTION

• After a new brake disc is installed, always

grind the brake disc with on-the-car type

brake lathe. If this step is not carried out, the

brake disc run-out exceeds the specified

value, resulting in judder.

•

AC006226AD

M12 Flat washer

M12 Flat washer

When the on-the-car type lathe is used, first

install M12 flat washer on the stud bolt in the

brake disc side according to the figure, and

then install the adapter. If the adapter is

installed with M12 flat washer not seated, the

brake disc rotor may be deformed, resulting

in inaccurate grinding.

• Grind the brake disc with all wheel nuts diag-

onally and equally tightened to the specified

torque 100 N

⋅m. When all numbers of wheel

nuts are not used, or the tightening torque is

excessive or not equal, the brake disc rotor or

drum may be deformed, resulting in judder.

5. If the run-out cannot be corrected by changing the

phase of the brake disc, replace the brake disc or

grind it with the on-the-car type brake lathe

("MAD, DL-8700PF" or equivalent).

BRAKE LINING THICKNESS CHECK

M1351003000527

CAUTION

• Whenever the shoe and lining assembly is

replaced, replace both RH and LH assemblies

as a set to prevent the car from pulling to one

side when braking.

• If there is a significant difference in the thick-

ness of the shoe and lining assemblies on the

left and right sides, check the sliding condi-

tion of the piston.

AC207894 AB

Bolts

(M8 x 1.25)

1. Use M8

×1.25 bolts as shown to remove the brake

drum by tightening them evenly.

ACX00708

A

AF

2. Measure the thickness of the brake lining at the

area with the worst wear.

Standard value: 4.0 mm

Minimum limit: 1.0 mm

3. Replace the shoe and lining assembly if the brake

lining thickness is less than the limit or if it is not

worn evenly. For installation procedures for the

shoe and lining assembly, refer to

Main

Index

Group

TOC