Mitsubishi Colt Ralliart. Manual - part 124

STARTING SYSTEM

ENGINE ELECTRICAL

16-30

DISASSEMBLY SERVICE POINTS

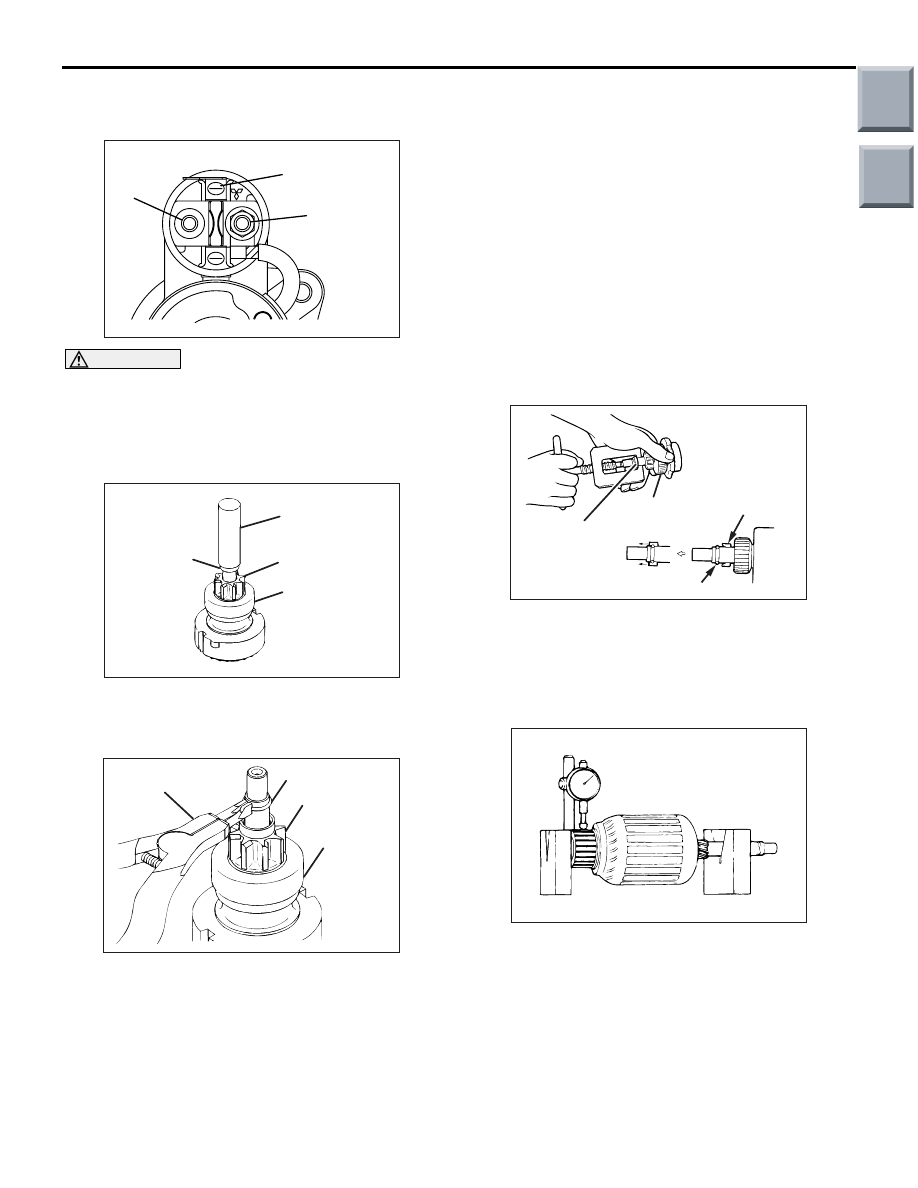

<<A>> MAGNETIC SWITCH REMOVAL

AK201882

B terminal

M terminal

S terminal

AC

CAUTION

Do not clamp the yoke assembly with a vise.

Disconnect the lead from the M terminal of the mag-

netic switch.

<<B>> SNAP RING/STOP RING REMOVAL

AK202790

Socket wrench

Stop ring

Pinion Gear

Overrunning

clutch

AB

1. Apply a long socket wrench of an appropriate size

to the stop ring and strike the wrench to drive out

the stop ring toward the pinion gear side.

AK202791

Snap ring

pliers

Snap ring

Pinion gear

Overrunning

clutch

AB

2. Remove the snap ring with snap ring pliers, then

remove the stop ring and overrunning clutch.

STARTER MOTOR PARTS CLEANING

Never clean in a solvent such starter motor parts as

the magnetic switch, brush holder, and armature.

If they are soaked in a solvent, their insulation

could be impaired. When these parts require

cleaning, wipe off contamination with cloth.

1. Never soak the drive unit in a solvent. If it is

washed in a solvent, the grease having been

packed in the overrunning clutch at the factory will

be washed out. Wipe the drive unit with cloth if it

requires cleaning.

REASSEMBLY SERVICE POINTS

>>A<< STOP RING/SNAP RING INSTAL-

LATION

AK202911

Overrunning

clutch

Stop ring

Snap ring

Stop ring

AB

Use a suitable puller to pull the stop ring until it gets

over the snap ring.

INSPECTION

M1162001300265

COMMUTATOR

AK202712

1. Support the armature with a pair of V block and

turn it to measure the runout of the surface not

rubbed by the brushes using a dial gauge.

Standard value: 0.02 mm or less

Limit: 0.05 mm

Main

Index

Group

TOC