Mitsubishi Colt Ralliart. Manual - part 3

ON-VEHICLE SERVICE

ENGINE MECHANICAL <4A9>

11A-9

IGNITION TIMING CHECK

M1111001701428

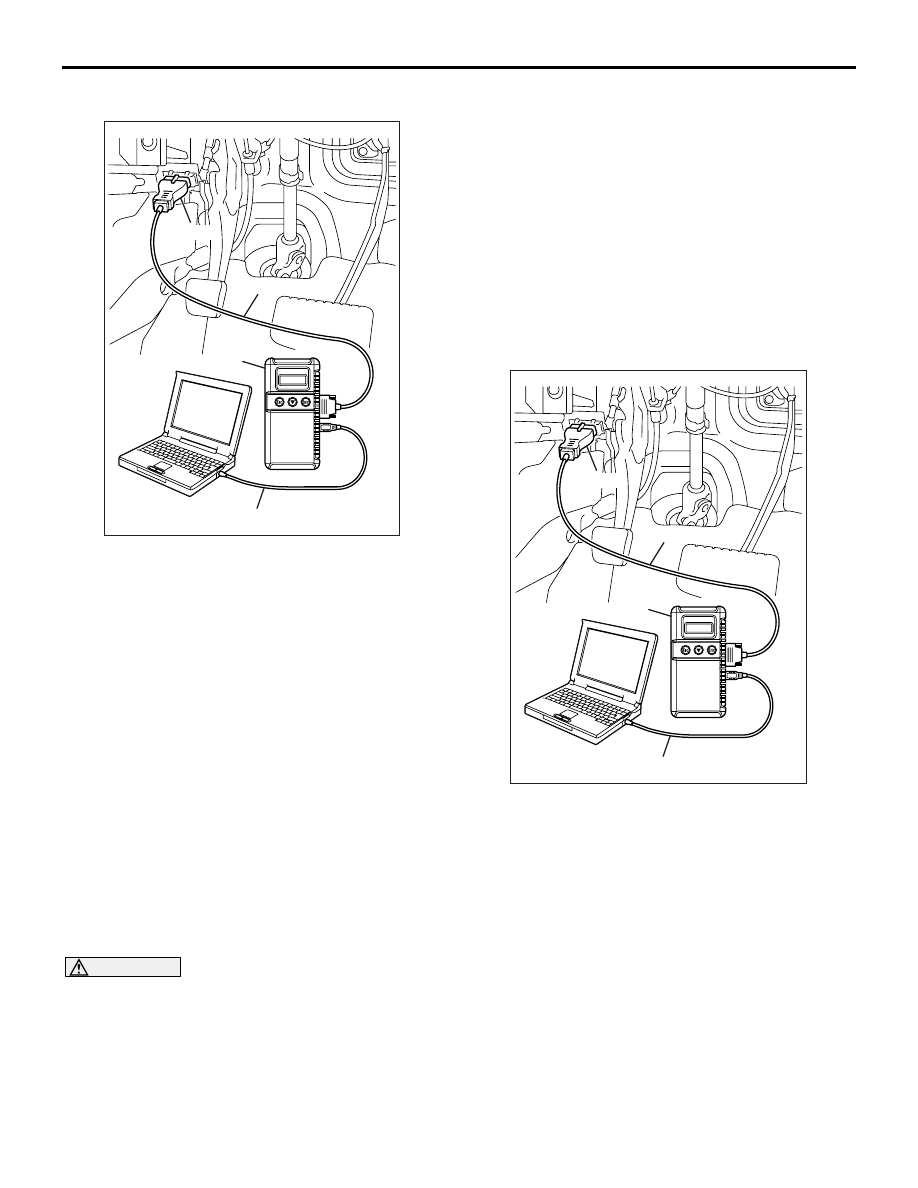

AK203215

MB991910

16-PIN

MB991827

MB991824

AC

1. Before inspection, set the vehicle to the

pre-inspection condition.

2. Turn the ignition switch to the "LOCK" (OFF)

position and then connect the M.U.T.-III to the

diagnosis connector.

3. Set the timing light to the power supply line

(terminal No.1) of the ignition coil No.1.

4. Start the engine and let it run at idle.

5. Select item No. 22 on the M.U.T.-III to measure

engine idle speed and check that it is

approximately 700 r/min.

6. Select No. 17 of the M.U.T.-III Actuator test.

7. Check that basic ignition timing is within the

standard value.

Standard value: 5

° BTDC ± 3°

8. If the basic ignition timing is outside the standard

value, inspect the MPI system (Refer to GROUP

13A

− Troubleshooting − Inspection chart for

diagnosis code

).

CAUTION

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this con-

dition may damage the engine.

9. Press the M.U.T.-III clear key (Select a forced

driving cancel mode) to release the Actuator test.

10.Check that ignition timing is at the standard value.

Standard value: approximately 10

° BTDC

NOTE:

.

•

The ignition timing may fluctuate within

±

7

°

BTDC. This is normal.

•

In higher altitude, the ignition timing is more

advanced than the standard value by approxi-

mately 5

°

.

11.Remove the timing light.

12.Turn off the ignition switch and then remove the

M.U.T.-III.

IDLE SPEED CHECK

M1111003501293

AK203215

MB991910

16-PIN

MB991827

MB991824

AC

1. Before inspection, set the vehicle to the

pre-inspection condition.

2. Turn the ignition switch to "LOCK" (OFF) position.

3. Connect the M.U.T.-III to the diagnosis connector.

4. Set the timing light to the power supply line

(terminal No.1) of the ignition coil No.1.

5. Start the engine and let it run at idle.

6. Check that ignition timing is at the standard value.

Standard value: approximately 10

° BTDC

7. Check the idle speed.

Standard value: 700

± 50 r/min

NOTE:

.

•

The idle speed is controlled automatically by

the idle speed control system.

•

When using the M.U.T.-III, select item No. 22

and take a reading of the idle speed.