Mitsubishi Canter (FE, FG). Manual - part 32

128

7 Construction of bodies

7.6 BlueTec

®

system

MITSUBISHI FUSO body/equipment mounting directives for FE, FG Issue date: 06. 07. 2012

!

Only print out complete sections from the current version

i

7.6 BlueTec

®

system

7.6.1

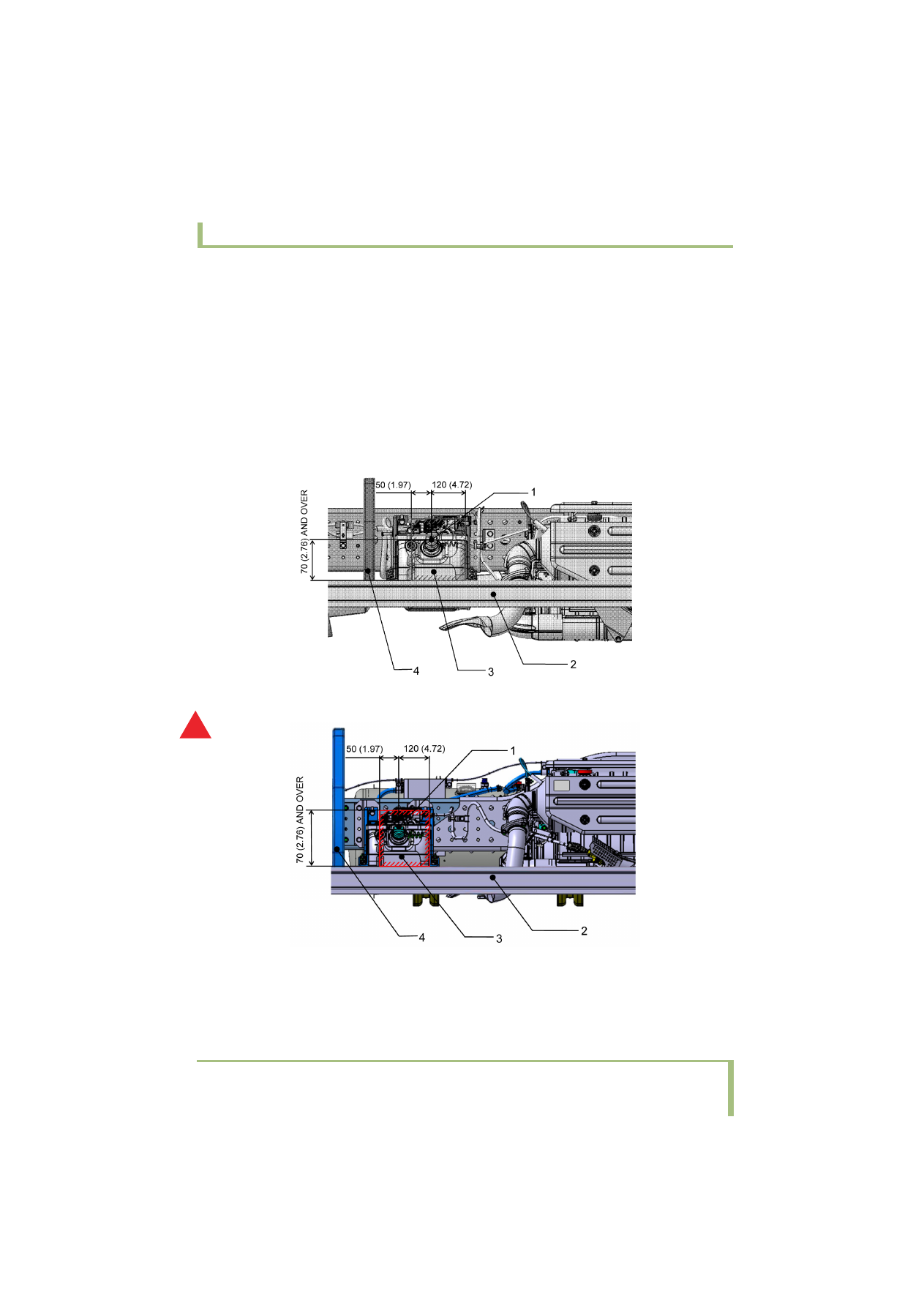

Installing a side guard and other parts around the DEF tank

• Care is required when installing a side guard around the DEF tank. Do not let the side guard and its mounting

bracket(s) hide the filler cap of the tank and interfere with refilling the tank with DEF. Be sure to open up

sufficient space around the cap to allow a filler nozzle of DEF to be inserted; typical dimensions of filler guns

are shown in the figures below.

• Allow a clearance of at least 25 mm {0.98 in.} between the side guard, mud guard, etc. installed around the

DEF tank and the following parts of the DEF tank: front end, rear end, and outer side.

• Avoid directly attaching parts to any of the DEF tank brackets.

• Maintain sufficient free space to insert DEF filler nozzle. (shaded area)

<FE>

Fig.1

<FG>

Fig.2

A

1

Cap

2

Side guard

3

DEF tank

4

Side guard mounting stay