Mitsubishi 380. Manual - part 978

AK201661

MD998812

MD998813

MD998821

MD998364

AD

Synchronizer

hub

OUTPUT SHAFT

MANUAL TRANSMISSION OVERHAUL

22B-25

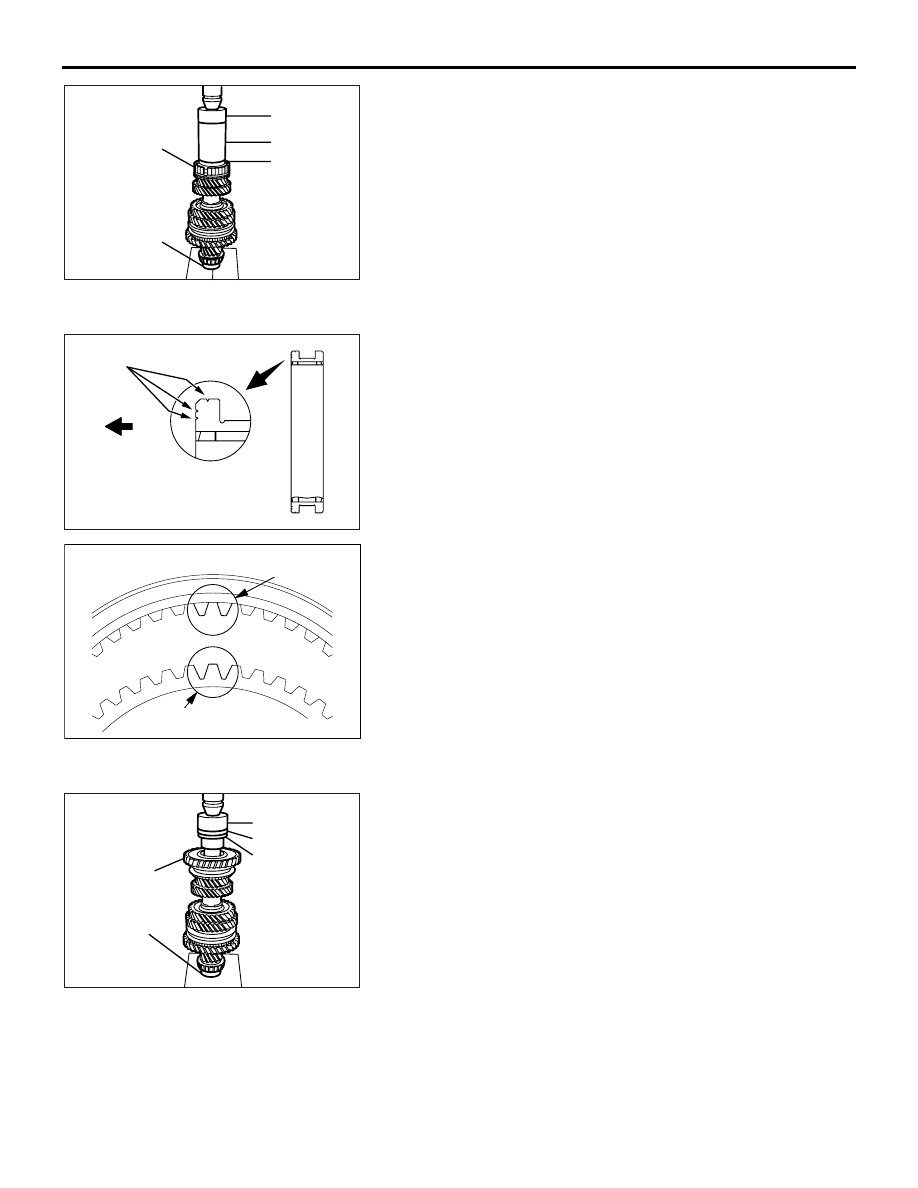

4. Using special tools, press install the 5th speed-reverse

synchronizer hub with the press.

• Installer cap (MD998812)

• Installer-100 (MD998813)

• Installer adapter (MD998821)

• Camshaft oil seal installer (MD998364)

5. Make sure that the synchronizer ring on the 5th speed gear

side can rotate freely.

.

>>N<< SYNCHRONIZER SLEEVE INSTALLATION

AK400081

Installation

direction

(5th speed side)

Identification

groove

AB

1. Check that the synchronizer sleeve is in the correct direction

for installation, and install it on the 5th speed-reverse

synchronizer hub.

AKX00928AD

Teeth with

raised tips

Deep grooves

between the teeth

2. Install the synchronizer sleeve so that the areas with teeth

that have raised tips (three areas total) are aligned with the

areas on the synchronizer hub that have deep grooves

between the teeth (three areas total).

.

>>O<< REVERSE GEAR BEARING SLEEVE INSTALLATION

AK201662AD

MD998364

MD998812

MD998820

Reverse

gear sleeve

Reverse

gear

1. Make sure the synchronizer ring, reverse gear and needle

roller bearing have been correctly installed.

2. Using special tools, press fit the reverse gear sleeve. Make

sure that the reverse gear and the synchronizer ring can

rotate freely during the pressing process.

• Installer cap (MD998812)

• Installer adapter (MD998820)

• Camshaft oil seal installer (MD998364)

.