Mitsubishi 380. Manual - part 885

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL

54A-74

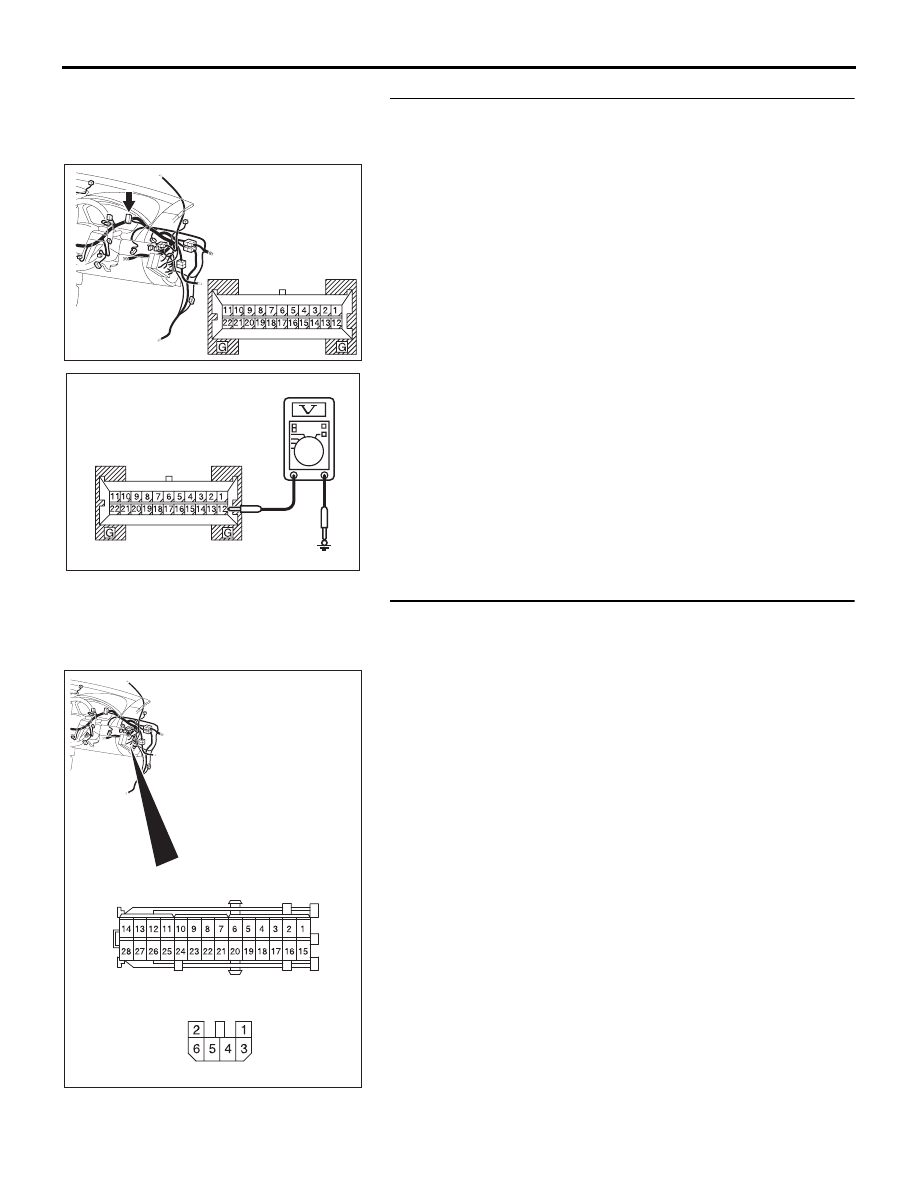

STEP 4. Measure the voltage at combination meter

connector C-101 in order to power supply circuit to

combination meter (IG1 power supply).

(1) Disconnect combination meter connector C-101, and

measure at the wiring harness side.

(2) Turn the ignition switch to "ON" position.

(3) Measure the voltage between terminal 12 and ground.

• The voltage should measure approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approximately 12 volts (battery

positive voltage)?

YES : Go to Step 6.

NO : Go to Step 5.

STEP 5. Check the wiring harness between combination

meter connector C-101 (terminal 12) and the ignition

switch (IG1)

NOTE: Also check junction block connector C-211 and C-215

for loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If inspecting junction block connector

C-211 or C-215 is damaged, repair or replace. Refer to

GROUP 00E, Harness Connector Inspection

Q: Is the wiring harness between combination meter

connector C-101 (terminal 12) and the ignition switch

(IG1) in good condition?

YES : Retest the system.

NO : Repair the wiring harness. Check that the

combination meter is normally.

54DB019A

CONNECTOR: C-101

HARNESS SIDE

AC209365

CONNECTOR C-101

(HARNESS SIDE)

HU

25DB096A

CONNECTORS: C-211, C-215

HARNESS SIDE

C-211

HARNESS SIDE

C-215