Mitsubishi 380. Manual - part 832

SEAT BELTS WITH PRE-TENSIONER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

52B-252

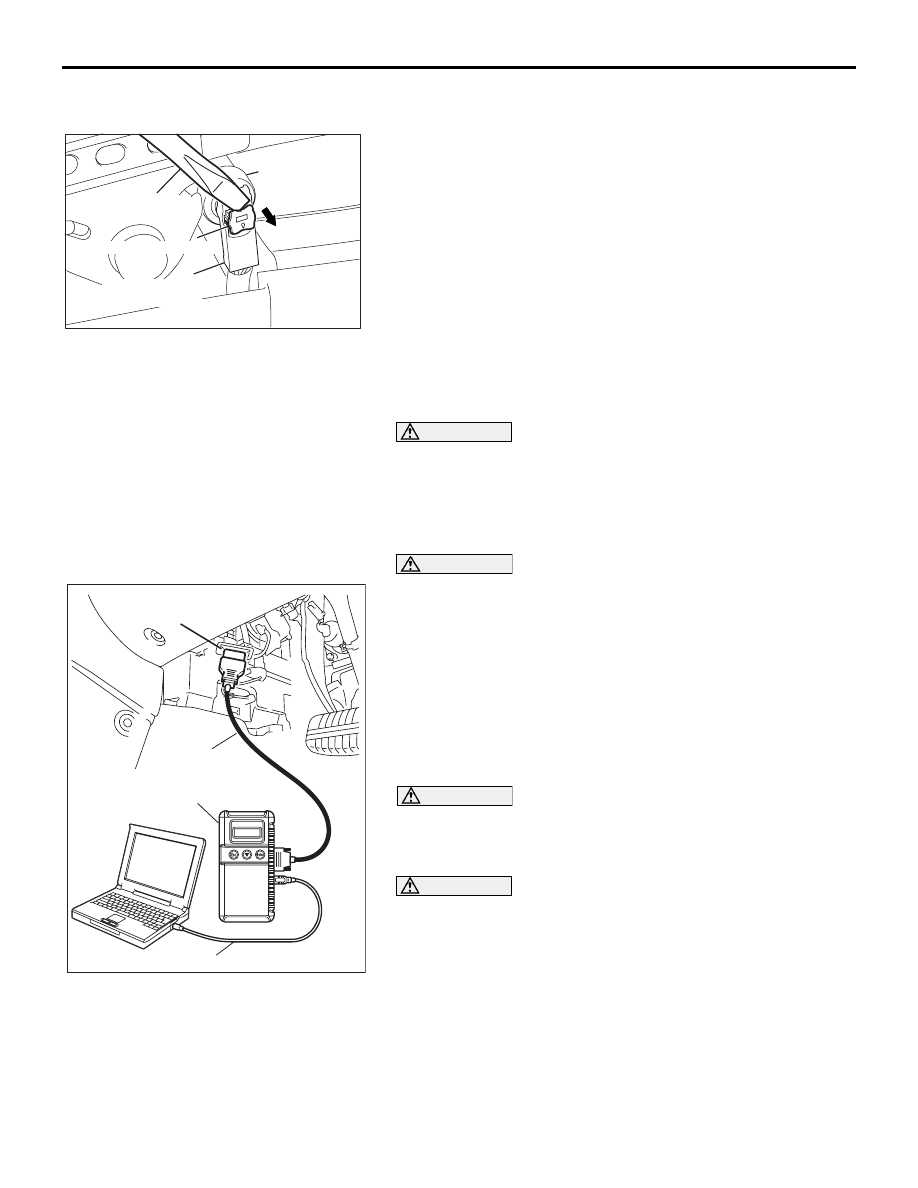

<<B>>PRE-TENSIONER CONNECTOR

DISCONNECTION

1. Use a flat-tipped screwdriver to unlock the locking button of

the harness-side connector by withdrawing it toward you in

two stages.

2. Disconnect the pretensioner connector.

INSTALLATION SERVICE POINTS

.

>>A<< PRE-INSTALLATION INSPECTION

WARNING

Dispose of seat belt pre-tensioner only according to

the specified procedure. (Refer to

).

1. When installing the new seat belt pre-tensioner, refer to

).

2. Connect the negative (

−) battery cable.

CAUTION

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

3. Connect diagnostic tool MB991958 to the data link

connector.

4. Turn the ignition switch to the “ON” position.

5. Check DTCs using diagnostic tool MB991958 to ensure

entire SRS operates properly.

At this time, check that no DTC except 26 and 28 are set.

DANGER

Wait at least 60 seconds after disconnecting the bat-

tery cable before doing any further work. (Refer to

).

WARNING

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

6. Turn the ignition switch to the "LOCK" (OFF) position.

Disconnect the negative (

−) battery cable and tape the

terminal to prevent accidental connection and seat belt

pre-tensioner operation.

.

>>B<< PRE-TENSIONER CONNECTOR

CONNECTION

Connect the pretensioner connector then securely lock the

locking button of the harness-side connector.

AC103556AF

PRE-TENSIONER

CONNECTOR

LOCKING BUTTON

HARNESS SIDE

CONNECTOR

FLAT-TIP SCREW

DRIVER

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827