Mitsubishi 380. Manual - part 626

MULTIPORT FUEL INJECTION (MPI) DIAGNOSIS

MULTIPORT FUEL INJECTION (MPI) <3.8L ENGINE>

13A-596

STEP 3. Check the advance ignition timing.

Ignition timing is controlled by the ENGIN-ECUand will vary

depending on engine requirement..

Q: Is the advance ignition timing normal?

YES : Go to Step 4.

NO : Check that the crankshaft position sensor and timing

belt cover are in the correct position. Then confirm

that the malfunction symptom is eliminated.

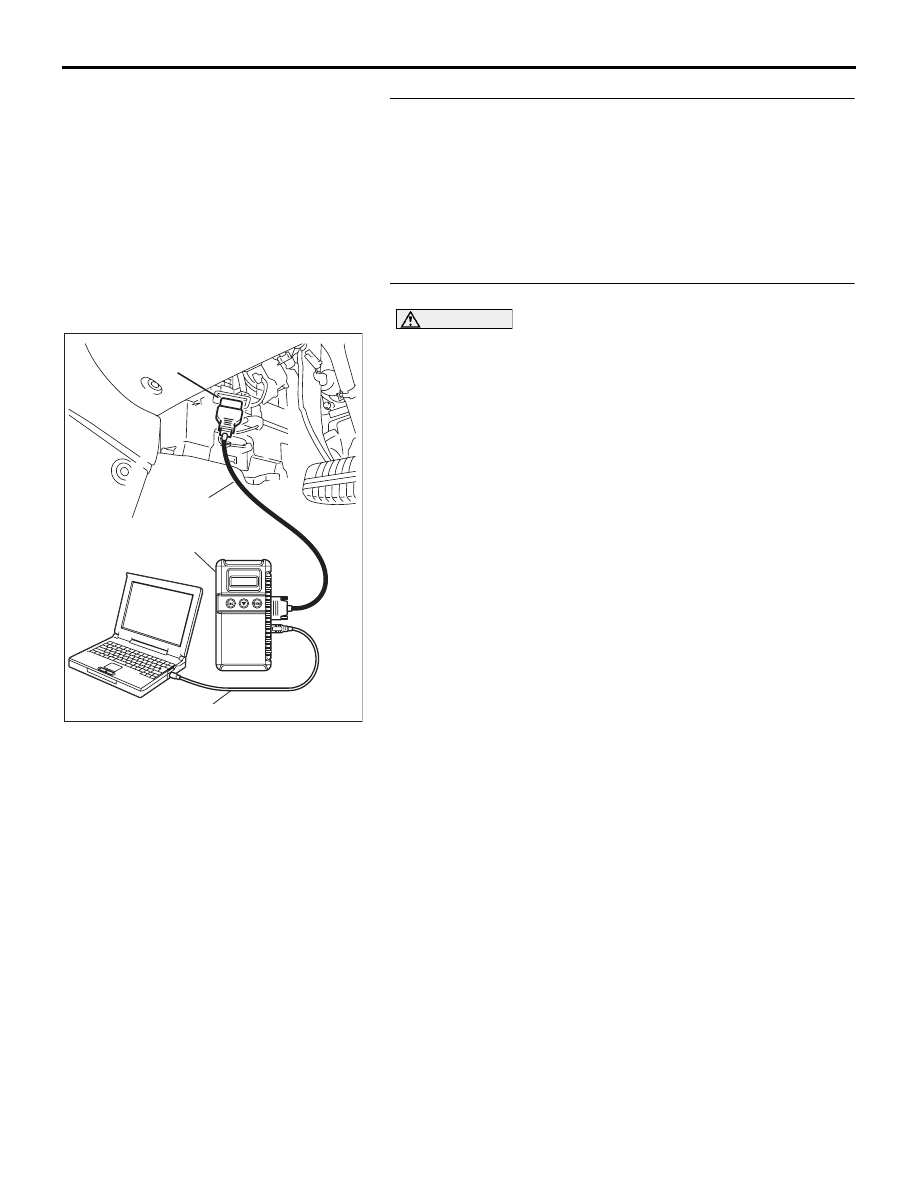

STEP 4. Using diagnostic tool, check data list.

CAUTION

To prevent damage to diagnostic tool, always turn the igni-

tion switch to the "LOCK" (OFF) position before connect-

ing or disconnecting diagnostic tool.

(1) Connect diagnostic tool to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Check the following items in the data list. Refer to Data List

.

a. Item 05: Intake Air Temperature Sensor.

b. Item 06: Engine Coolant Temperature Sensor.

c. Item AD: Right Bank Heated Oxygen Sensor (rear).

d. Item AC: Right Bank Heated Oxygen Sensor (front).

e. Item AF: Left Bank Heated Oxygen Sensor (rear).

f. Item AE: Left Bank Heated Oxygen Sensor (front).

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Are they operating properly?

YES : Go to Step 5.

NO : Repair or replace it. Then confirm that the malfunction

symptom is eliminated.

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827