Mitsubishi 380. Manual - part 613

MULTIPORT FUEL INJECTION (MPI) DIAG

MULTIPORT FUEL INJECTION (MPI)

13A-544

STEP 1. Using diagnostic tool , read the diagnostic trouble

code (DTC).

CAUTION

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Read the DTC.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC set?

YES : Refer to Diagnostic Trouble Code Chart.

NO : Go to step 2.

STEP 2. Check the trouble symptoms.

(1) Turn the ignition switch to the "ON" position.

• The malfunction indicator lamp (Check Engine Lamp)

should illuminate immediately after the ignition switch is

turned to the "ON" position.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Does the malfunction indicator lamp (Check Engine

Lamp) illuminate?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

− How to

Cope with Intermittent Malfunctions

.

NO : Replace the combination meter.

INSPECTION PROCEDURE 4: The Malfunction Indicator Lamp (Check Engine Lamp) Remains

Illuminated and Never Goes Out.

.

COMMENT

• In cases such as the above, the cause is proba-

bly that the ENGINE-ECU is detecting a problem

in a sensor or actuator, or that one of the mal-

functions listed at next has probably occurred.

.

TROUBLESHOOTING HINTS (The most

likely causes for this case:)

• Shorted the malfunction indicator lamp (Check

Engine Lamp) circuit.

• Refer to component locations GROUP-

• Refer to configuration diagrams GROUP-

• Refer to circuit diagrams GROUP-

DIAGNOSIS

Required Special Tools:

• Diagnostic Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

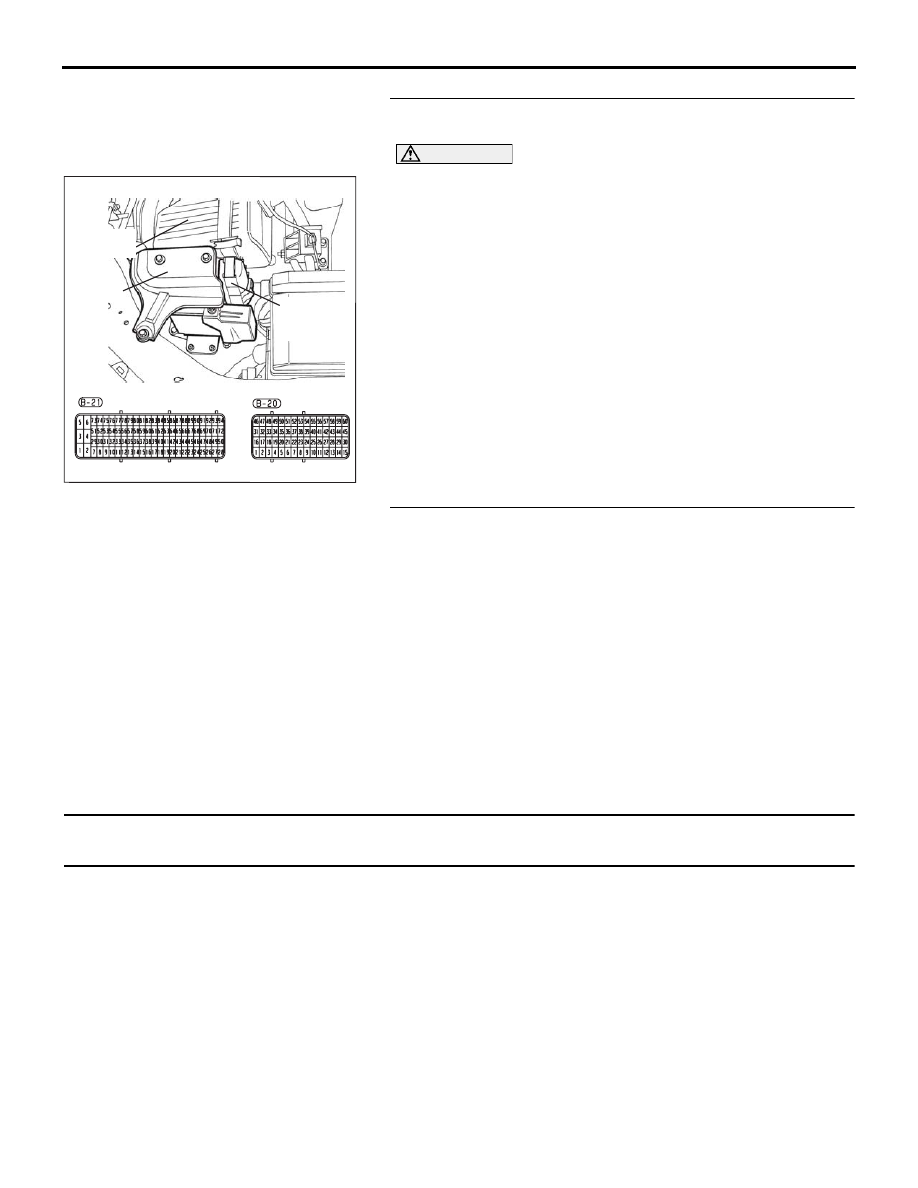

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER