Mitsubishi 380. Manual - part 604

MULTIPORT FUEL INJECTION (MPI) DIAG

MULTIPORT FUEL INJECTION (MPI)

13A-508

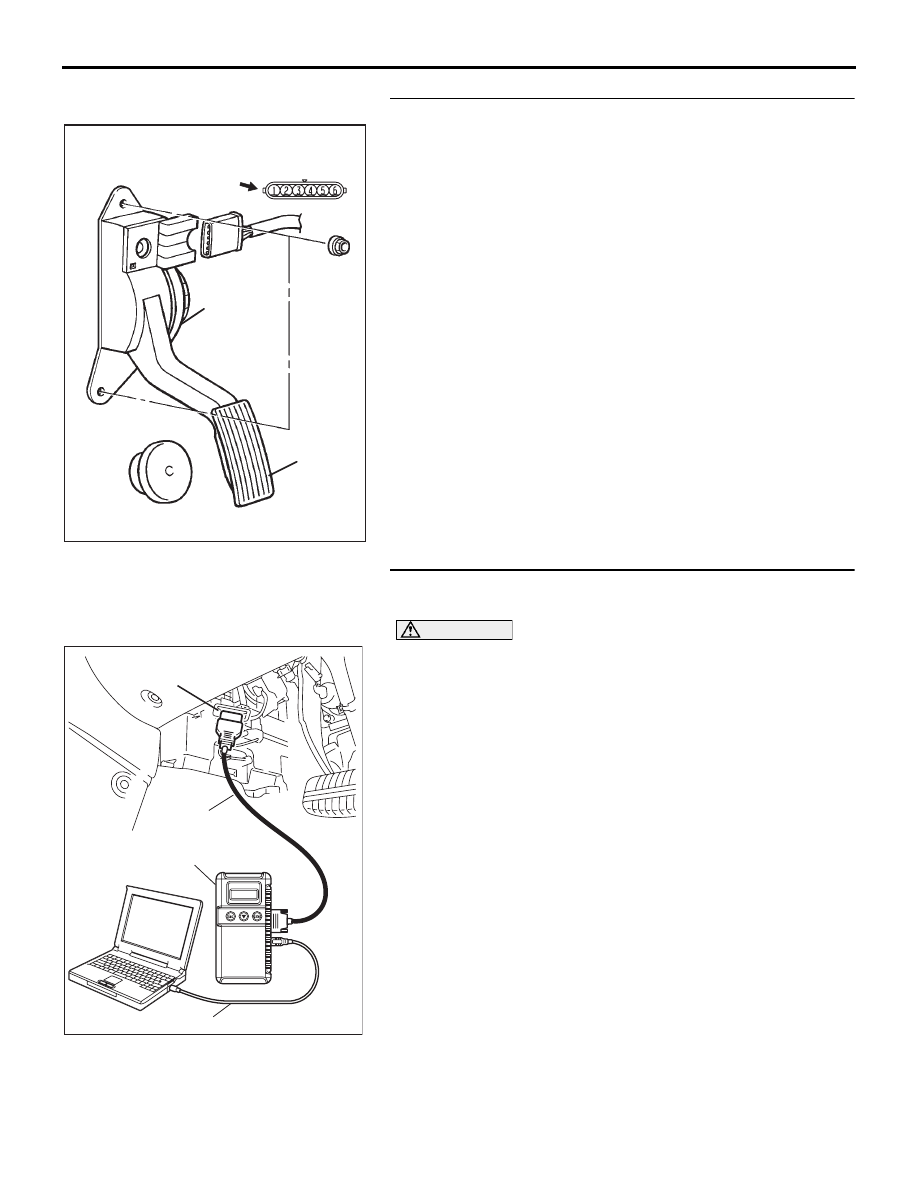

STEP 7. Replace the accelerator pedal position sensor.

(1) Replace the accelerator pedal position sensor.

(2) Turn the ignition switch to the "ON" position.

(3) After the DTC has been deleted, read the DTC again.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC P2128 set?

YES : Then go to Step 8.

NO : The inspection is complete.

STEP 8. Using diagnostic tool , check data list item 12:

Accelerator Pedal Position Sensor (sub).

CAUTION

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK"(OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set diagnostic tool to the data reading mode for

item 12,

Accelerator Pedal Position Sensor (sub).

• Output voltage is between 0435 and 1035 mV when foot

is released from accelerator pedal.

• Output voltage is between 4000 - 4824 mV when accel-

erator pedal is fully depressed.

(4) Turn the ignition switch to the "LOCK"(OFF) position.

Q: Is the sensor operating properly?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

− How to

Cope with Intermittent Malfunctions

.

NO : Then go to Step 9.

ACCELERATOR

PEDAL

CONNECTOR: C-24

C-24 (B)

ACCELERATOR

PEDAL POSITION

SENSOR

HARNESS

CONNECTOR:

COMPONENT SIDE

16DB562A

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827