Mitsubishi 380. Manual - part 570

MULTIPORT FUEL INJECTION (MPI) DIAGNOSIS

MULTIPORT FUEL INJECTION (MPI)

13A-372

13A

DTC P0340: Camshaft Position Sensor Circuit.

.

CIRCUIT OPERATION

• The camshaft position sensor power is supplied

from the ECU (terminal No. 25).

• Terminal No. 3 of the camshaft position sensor is

grounded with ECU (terminal No. 8).

• A 5-volt supply is applied to the camshaft position

sensor output terminal (terminal No. 2) from the

ECU (terminal No. 38). The camshaft position

sensor generates a pulse signal when the output

terminal is opened and grounded.

.

TECHNICAL DESCRIPTION

• The camshaft position sensor functions to detect

the top dead center position of the number 1 cyl-

inder and to convert that data to pulse signals

that are input to the ECU.

• When the engine is running, the camshaft posi-

tion sensor outputs a pulse signal.

• The ECU checks whether pulse signal is input

while the engine is cranking.

.

DTC SET CONDITIONS <Range/Performance problem - Alignment>

Check Conditions

• Engine speed is higher than 50 r/min.

Judgment Criteria

• Normal signal pattern has not been input for cyl-

inder identification from the crankshaft position

sensor signal and camshaft position sensor sig-

nal for 2 seconds.

• MIL activated immediately.

• Engine stalls.

.

DTC SET CONDITIONS <Range/Performance problem - Circuit continuity>

Check Conditions

• Engine speed is higher than 50 r/min.

Judgment Criteria

• Camshaft position sensor output voltage has not

changed (no pulse signal is input) for 2 seconds.

• MIL activated immediately.

• Engine stalls.

.

EOBD DRIVE CYCLE PATTERN

Refer to Diagnostic Function

− EOBD Drive Cycle −

.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are: )

• Camshaft position sensor failed.

• Open or shorted camshaft position sensor circuit.

• Harness or connector damage.

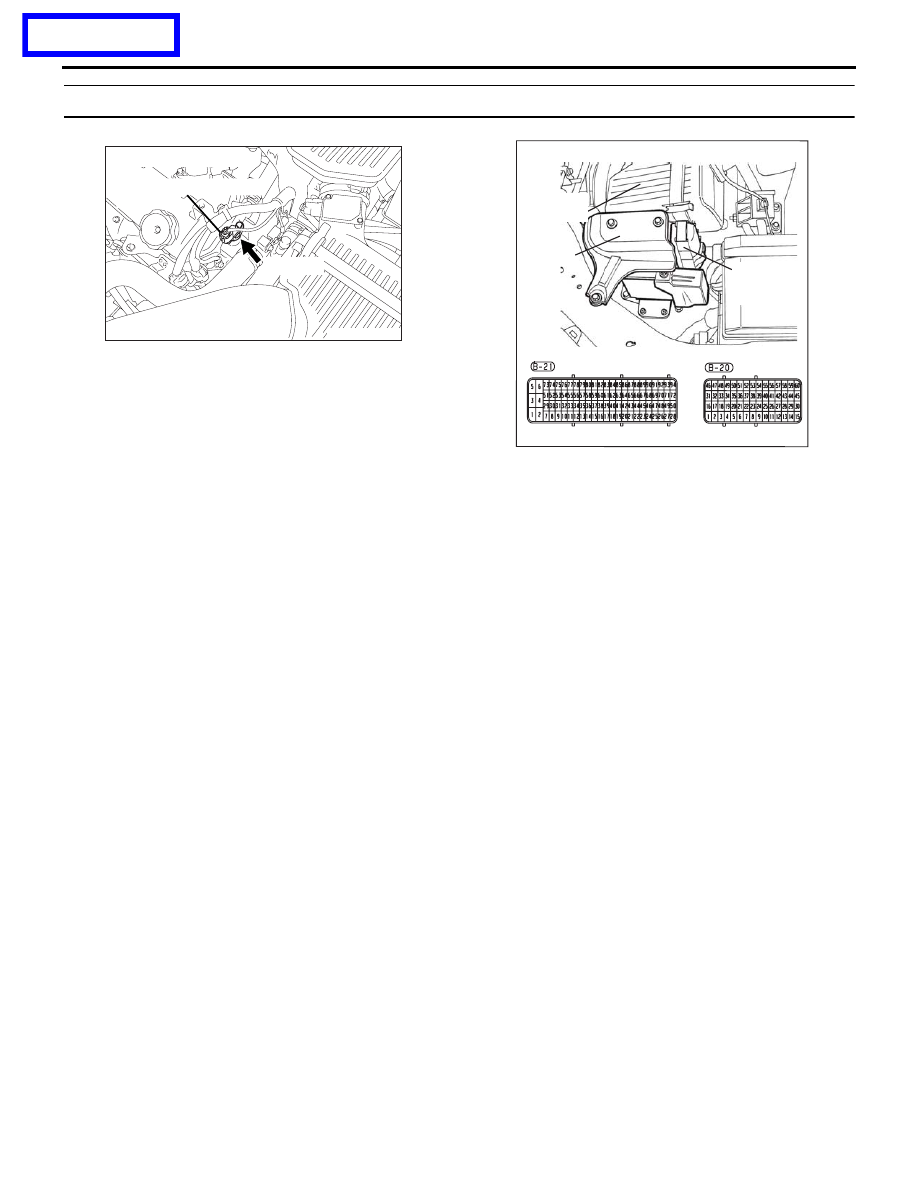

• Refer to component locations GROUP-

AK303129AB

CAMSHAFT POSITION

SENSOR

B-106 (B)

CONNECTOR: B-106

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER