Mitsubishi 380. Manual - part 499

MULTIPOINT FUEL INJECTION (MPI) DIAGNOSIS

MULTIPOINT FUEL INJECTION (MPI)

13A-88

DIAGNOSIS

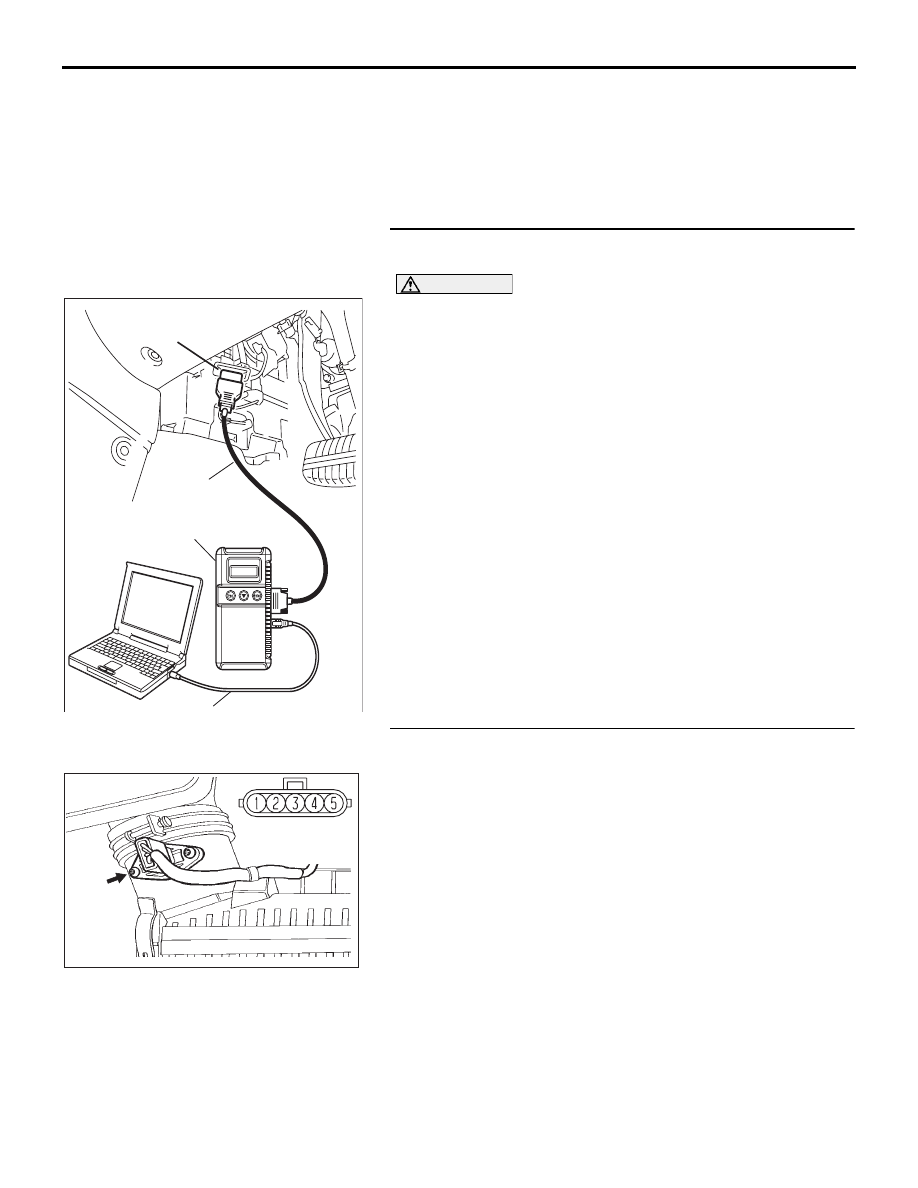

Required Special Tool:

• : Diagnostic Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

STEP 1. Using diagnostic tool , check data list item AA:

Mass Airflow Sensor.

CAUTION

To prevent damage to diagnostic tool , always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting diagnostic tool .

(1) Connect diagnostic tool to the data link connector.

(2) Start the engine and run at idle.

(3) Set diagnostic tool to the data reading mode for item AA,

Mass Airflow Sensor.

(4) Warm up the engine to normal operating temperature: 80

°C

to 95

°C (176°F to 203°F).

• The standard value during idling should be approxi-

mately 4.7 g/sec.

• When the engine is revved, the mass airflow rate should

increase according to the increase in engine speed.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

− How to

Cope with Intermittent Malfunctions

.

NO : Go to Step 2.

STEP 2. Check harness connector B-10 at mass airflow

sensor for damage.

Q: Is the harness connector in good condition?

YES : Go to Step 3.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 7.

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827

CONNECTOR: B-10

B-10 (GR)

03DB218A

HARNESS

CONNECTOR:

COMPONENT SIDE