Mitsubishi 380. Manual - part 445

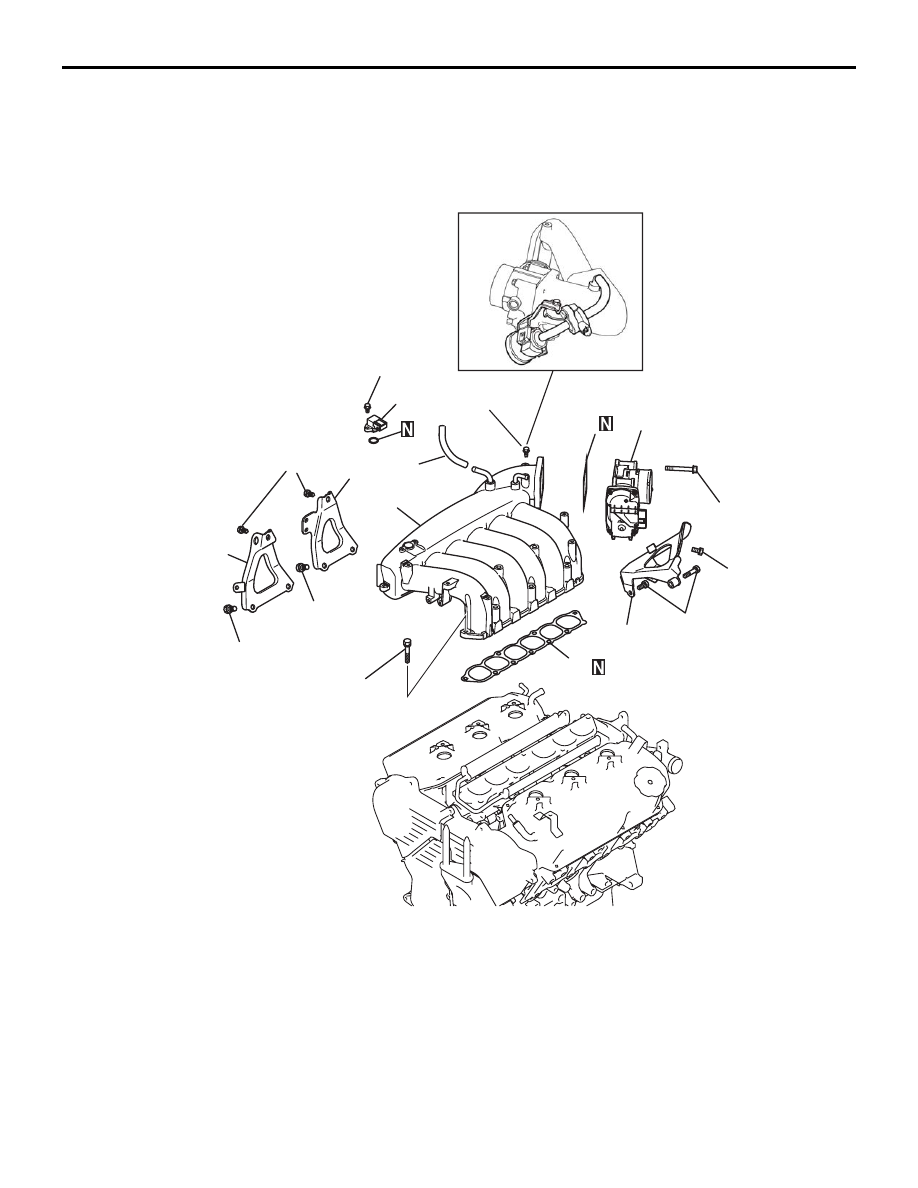

INTAKE MANIFOLD PLENUM AND THROTTLE BODY ASSEMBLY

ENGINE OVERHAUL <3.8L ENGINE>

11B-6

INTAKE MANIFOLD PLENUM AND THROTTLE BODY

ASSEMBLY

REMOVAL AND INSTALLATION

M1113003300173

10

2

1

5.0 ± 1.0 N·m

44 ± 9 in-lb

3

4

18 ± 2 N·m

13 ± 1 ft-lb

36 ± 6 N·m

27 ± 4 ft-lb

7

8

9

18 ± 2 N·m

13 ± 1 ft-lb

28 ± 4 N·m

21 ± 3 ft-lb

6

5

28 ± 4 N·m

21 ± 3 ft-lb

36 ± 6 N·m

27 ± 4 ft-lb

9.0 ± 1.0 N·m

80 ± 9 in-lb

18 ± 2 N·m

13 ± 1 ft-lb

03DB138A

REMOVAL STEPS

1.

PURGE HOSE

>>C<<

2.

PURGE VALVE ASSY

6.

INTAKE MANIFOLD PLENUM STAY,

FRONT

4.

INTAKE MANIFOLD PLENUM STAY,

REAR

5

THROTTLE BODY STAY

6

THROTTLE BODY

>>B<<

7

THROTTLE BODY GASKET

>>A<<

8

BOOST SENSOR

9

INTAKE MANIFOLD PLENUM

10 INTAKE MANIFOLD PLENUM VALVE

GASKET

REMOVAL STEPS (Continued)