Mitsubishi 380. Manual - part 423

AUTOMATIC TRANSMISSION DIAGNOSIS

AUTOMATIC TRANSMISSION

23A-232

INSPECTION PROCEDURE 7: Shift Shock when Shifting from "N" to "R" and Long Delay

.

COMMENT

If abnormal shock or delay of two seconds or more

occurs when the selector lever is shifted from "N" to

"R" range while the engine is idling, the cause is

probably abnormal reverse clutch pressure or

low-reverse brake pressure, or a malfunction of the

reverse clutch, low-reverse brake, valve body or TP

sensor.

.

TROUBLESHOOTING HINTS (The most

likely causes for this condition:)

• Abnormal reverse clutch pressure

• Abnormal low-reverse brake pressure

• Malfunction of the low-reverse solenoid valve

• Malfunction of the reverse clutch

• Malfunction of the low-reverse brake

• Malfunction of the valve body

• Malfunction of the TP sensor

• Malfunction of the A/T-ECU system

Circuit drawings

• Refer to circuit diagrams GROUP-

• Refer to configuration diagrams GROUP-

• Refer to component locations GROUP-

DIAGNOSIS

Required Special Tool:

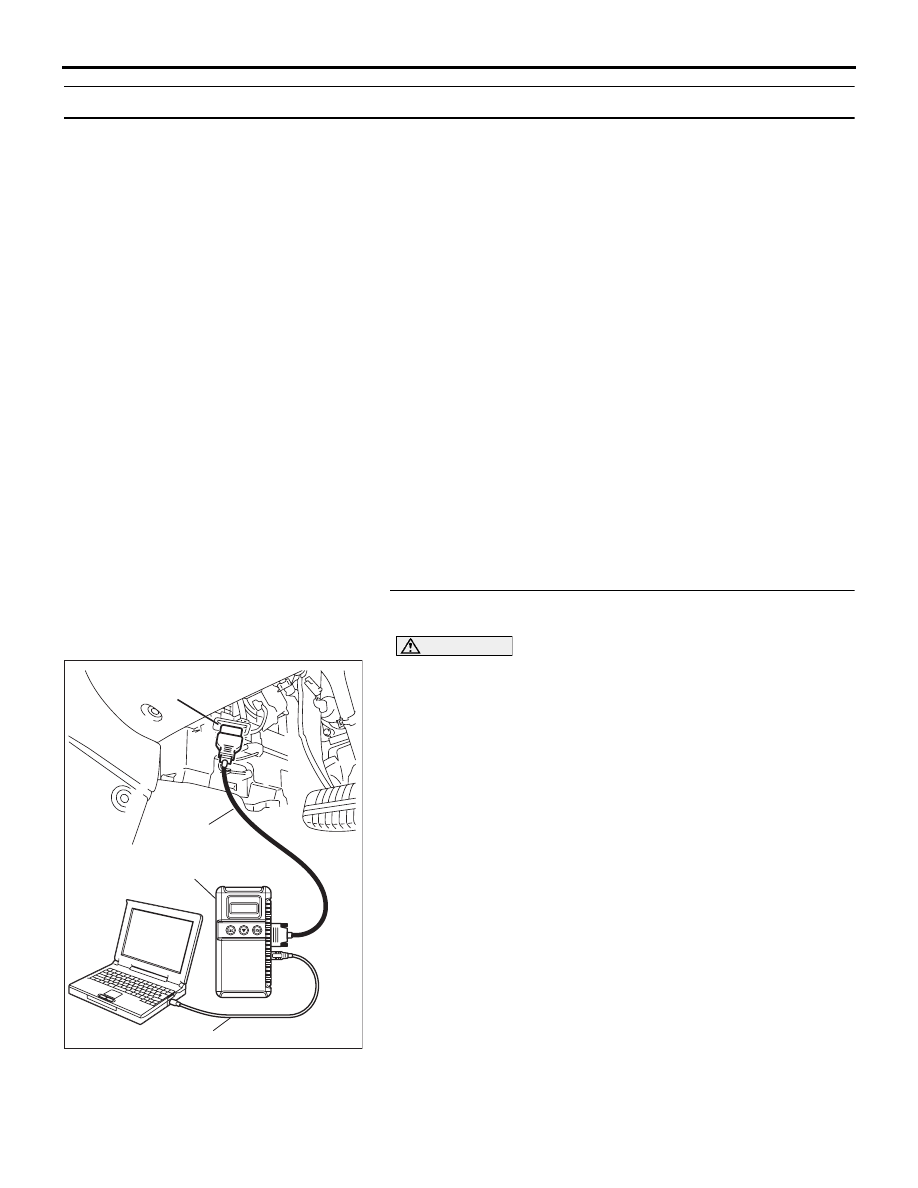

• MB991958: Diagnostic Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: MUT-III USB Cable

• MB991910: MUT-III Main Harness A

STEP 1. Using diagnostic tool MB991958, check actuator

test item 01: Low-Reverse Solenoid Valve.

CAUTION

To prevent damage to diagnostic tool MB991958, always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting diagnostic tool

MB991958.

(1) Connect diagnostic tool MB991958 to the data link

connector.

(2) Turn the ignition switch to the "ON" position.

(3) Set diagnostic tool MB991958 to the actuator test mode.

• Item 01: Low-Reverse Solenoid Valve.

• An audible clicking or buzzing should be heard when

the low-reverse solenoid valve is energized.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the solenoid valve operating properly?

YES : Go to Step 2.

NO : Repair or replace the low-reverse solenoid valve.

Refer to GROUP 23B, Valve Body

. Then

confirm that the symptom is eliminated.

00DB076A

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827