Mitsubishi 380. Manual - part 309

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-14

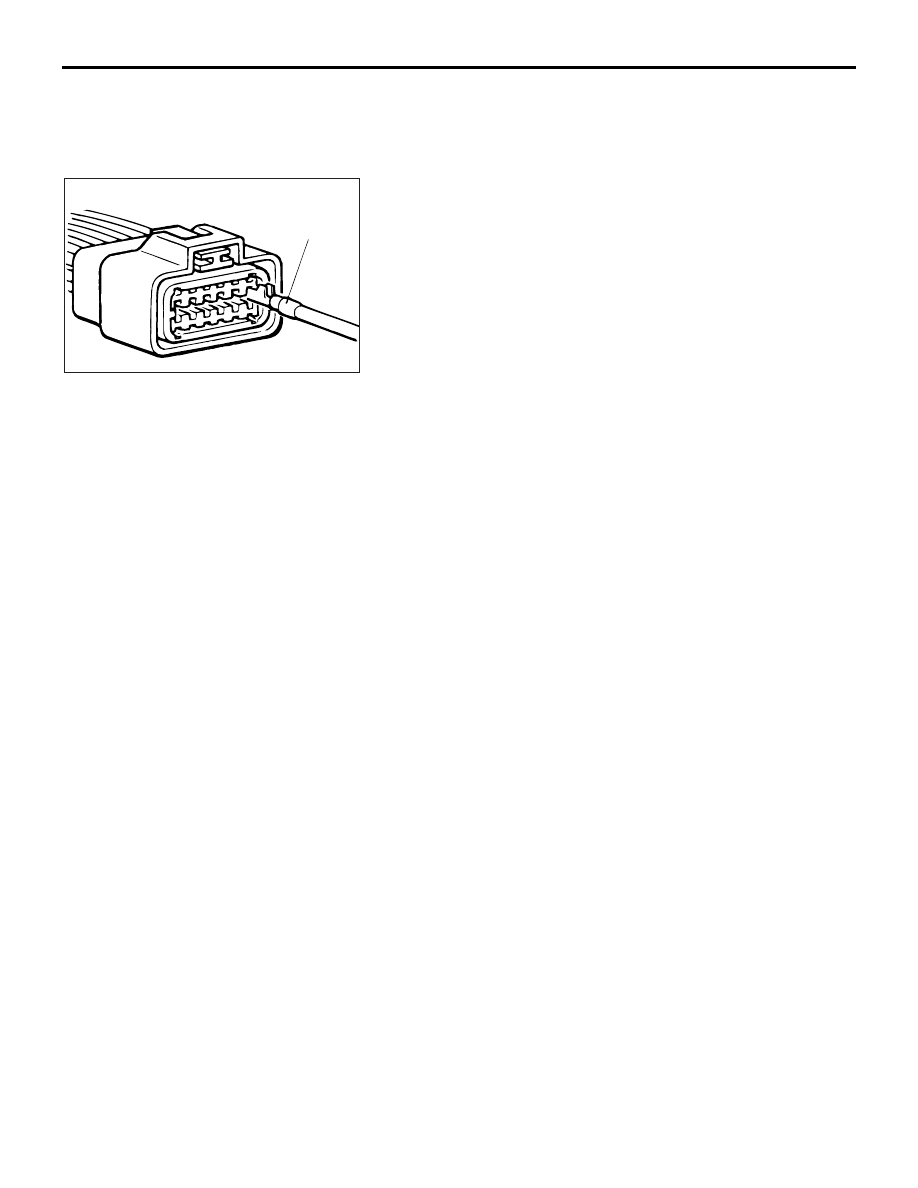

CONNECTOR ENGAGEMENT INSPECTION

Required Special Tool:

• MB991219: Inspection Harness (contained in MB991223

Test Harness)

Use special tool MB991219 to inspect the engagement of the

male pins and female pins. [Pin drawing force: 1 N (0.2 pound)

or more]

HOW TO COPE WITH INTERMITTENT

MALFUNCTIONS

M1001013900064

Most intermittent malfunctions occur under certain conditions. If

those conditions can be identified, the cause will be easier to

find.

.

TO COPE WITH INTERMITTENT MALFUNCTION;

1. ASK THE CUSTOMER ABOUT THE

MALFUNCTION

Ask what it feels like, what it sounds like, etc. Then ask about

driving conditions, weather, frequency of occurrence, and so

on.

.

2. DETERMINE THE CONDITIONS FROM THE

CUSTOMER'S RESPONSES

Typically, almost all intermittent malfunctions occur from condi-

tions like vibration, temperature and/or moisture change, poor

connections. From the customer's responses, it should be rea-

soned which condition is most likely.

.

3. USE SIMULATION TEST

Use the simulation tests below to attempt to duplicate the cus-

tomer's complaint. Determine the most likely circuit(s) and per-

form the simulation tests on the connectors and parts of that

circuit(s). Be sure to use the inspection procedures provided for

diagnostic trouble codes and trouble symptoms.

For temperature and/or moisture condition related intermittent

malfunctions, try to change the conditions of the suspected cir-

cuit components, then use the simulation tests below.

.

ACX00870 AB

MB991219