Mitsubishi 380. Manual - part 295

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-14

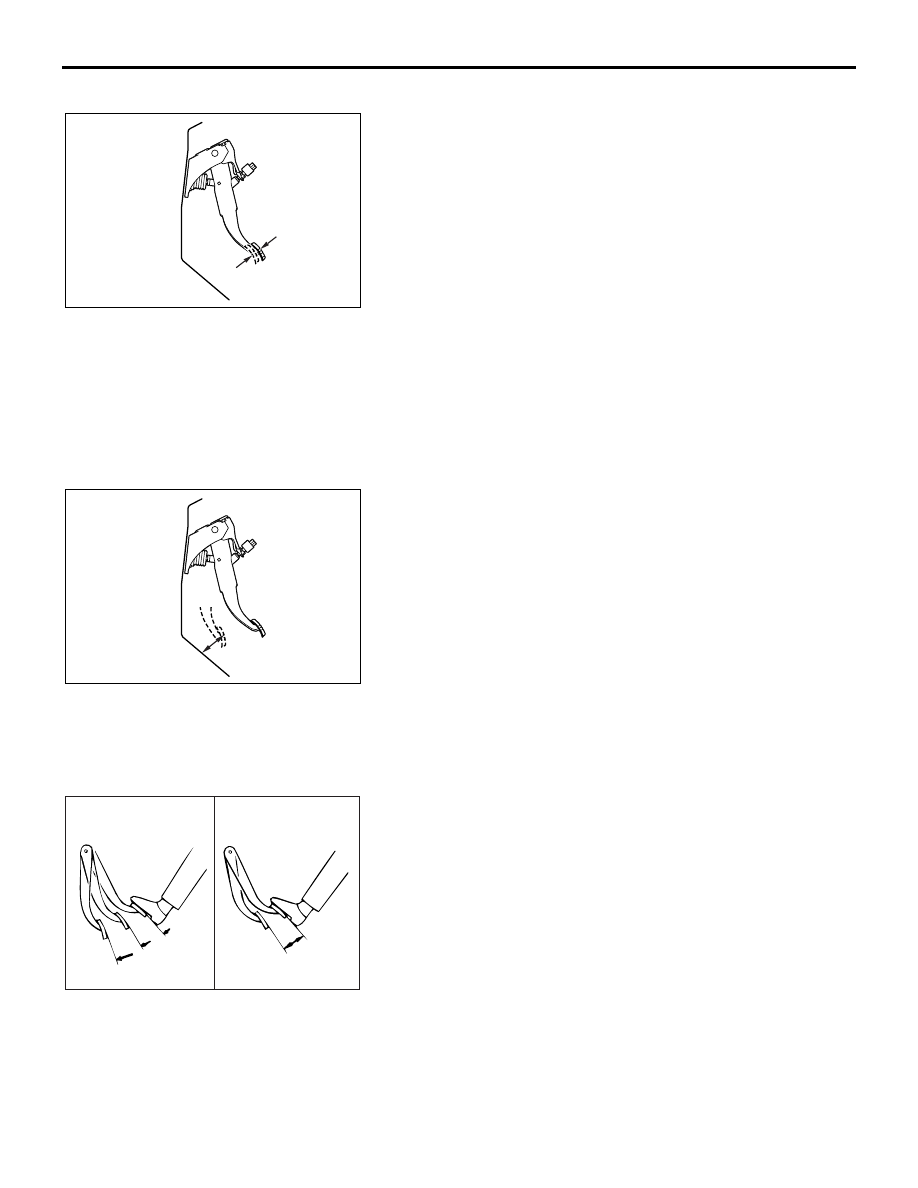

BRAKE PEDAL FREE PLAY

1. Turn the ignition switch to the "LOCK" (OFF) position, and

depress the brake pedal two or three times. After eliminating

the vacuum in the brake booster, press the pedal down by

hand, and confirm that the amount of movement before

resistance is met (free play) is within the standard value

range.

Standard value: 3

− 8 mm (0.12 − 0.31 inch)

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

• Excessive play between the brake pedal and the clevis pin,

or between the clevis pin and the brake booster operating

rod

• Brake pedal height

• Installation position of the stop light switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND

DASH PANEL

1. Turn up the carpet, etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N (112 pounds) of force, and measure

the clearance between the brake pedal and the dash panel.

Standard value: 110 mm (4.33 inches) or more [From

the surface of dash panel to the face of pedal pad]

3. If the clearance is outside the standard value, check for air

trapped in the brake line and check the thickness of the disc

brake pad. Andjust and replace defective parts as required.

4. Return the carpet etc. to its original position.

BRAKE BOOSTER OPERATING TEST

M1351001000372

1. For simple checking of the brake booster operation, carry

out the following tests:

(1) Run the engine for one or two minutes, and then stop it. If

the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective. Go to step 2.

AC206445

AB

AC206446

AB

AC000870

GOOD

NO GOOD

AB