Mitsubishi 380. Manual - part 235

ENGINE COOLING DIAGNOSIS

ENGINE COOLING

14-24

STEP 6. Check the fan controller.

(1) Disconnect fan controller connector A-24.

(2) Back out connector terminal pin 2 from connector housing.

(3) Reconnect the connector with connector terminal pin 2 still

removed.

(4) Turn the ignition switch to the "ON" position.

(5) Check for the cooling fan operation.

• The cooling fan rotates. (with connector terminal pin 2

disconnected)

(6) Check for the cooling fan operation.

• Using a suitable probe connect the fan controller termi-

nal 2 at controller side to earth.The cooling fan stops.

(When pin 2 of fan controller is connected to earth)

(7) Turn the ignition switch to the "OFF" position.

(8) Disconnect fan controller connector A-24, and re-locate

connector terminal pin 2 into connector housing.

(9) Reconnect the connector with connector terminal pin 2

installed correctly.

Q: Does the cooling fan rotate? And when the fan

controller pin 2 is connected to the body earth, does

the cooling fan stop?

YES : Go to Step 7.

NO : Replace the fan motor and fan controller (Refer to

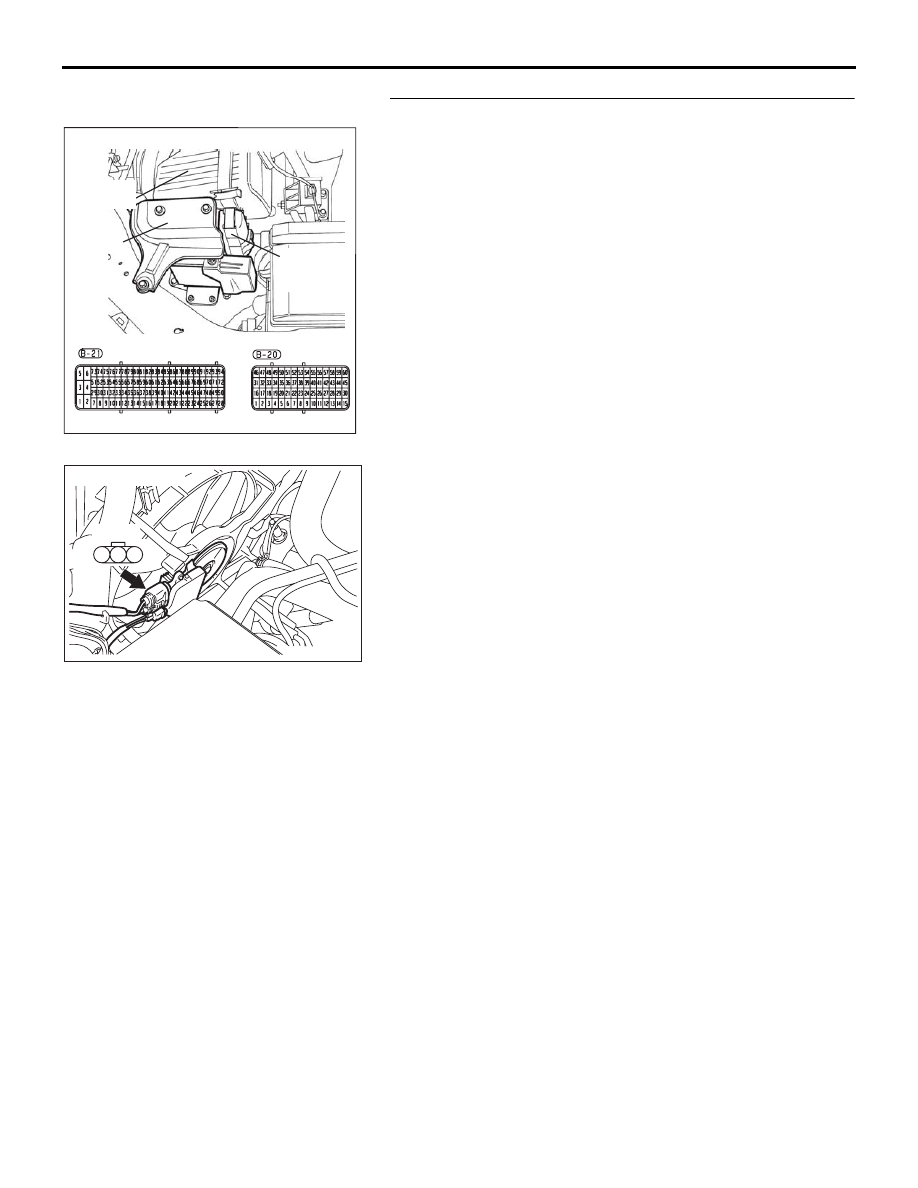

16DB400A

COVER

ENGINE

CONTROL

UNIT

AIR

CLEANER

04DB008A

1

2

3

A-24

Connector: A-24