Mitsubishi 380. Manual - part 73

SYMPTOM PROCEDURES

SIMPLIFIED WIRING SYSTEM (SWS)

54B-289

STEP 31. Check the wiring harness between licence plate

lamp connector F-06 (terminal 1) and ground.

Q: Is the wiring harness between licence plate lamp

connector F-06 (terminal 1) and ground in good

condition?

YES : Replace the licence plate lamp socket. Verify that the

licence plate lamps illuminate normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the licence plate lamps illuminate normally.

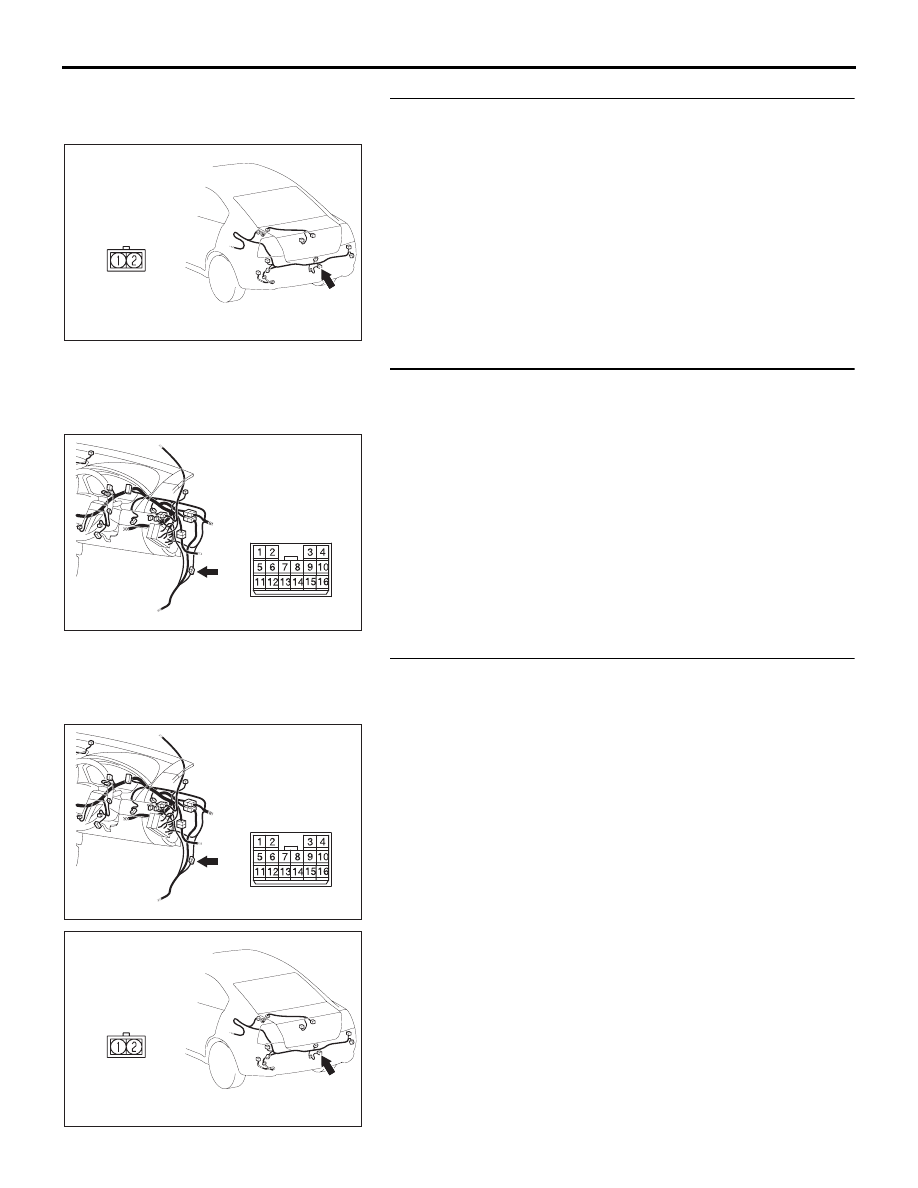

STEP 32. Check intermediate connector C-25 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is intermediate connector C-25 in good condition?

YES : Go to Step 33.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

. Check that the licence plate lamps illuminate

normally.

STEP 33. Check the wiring harness between licence plate

lamp connector F-06 (terminal 2) and intermediate

connector C-25 (terminal 10).

Q: Is the wiring harness between licence plate lamp

connector F-06 (terminal 2) and intermediate connector

C-25 (terminal 10) in good condition?

YES : Replace the licence plate lamp socket. Verify that the

licence plate lamps illuminate normally.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that

the licence plate lamps illuminate normally.

16DB438A

HARNESS SIDE

CONNECTOR: F-06

16DB435A

CONNECTOR: C-25

16DB435A

CONNECTOR: C-25

16DB438A

HARNESS SIDE

CONNECTOR: F-06