Mitsubishi Grandis. Manual - part 942

TROUBLESHOOTING

TRACTION CONTROL/ACTIVE STABILITY CONTROL SYSTEM

35C-93

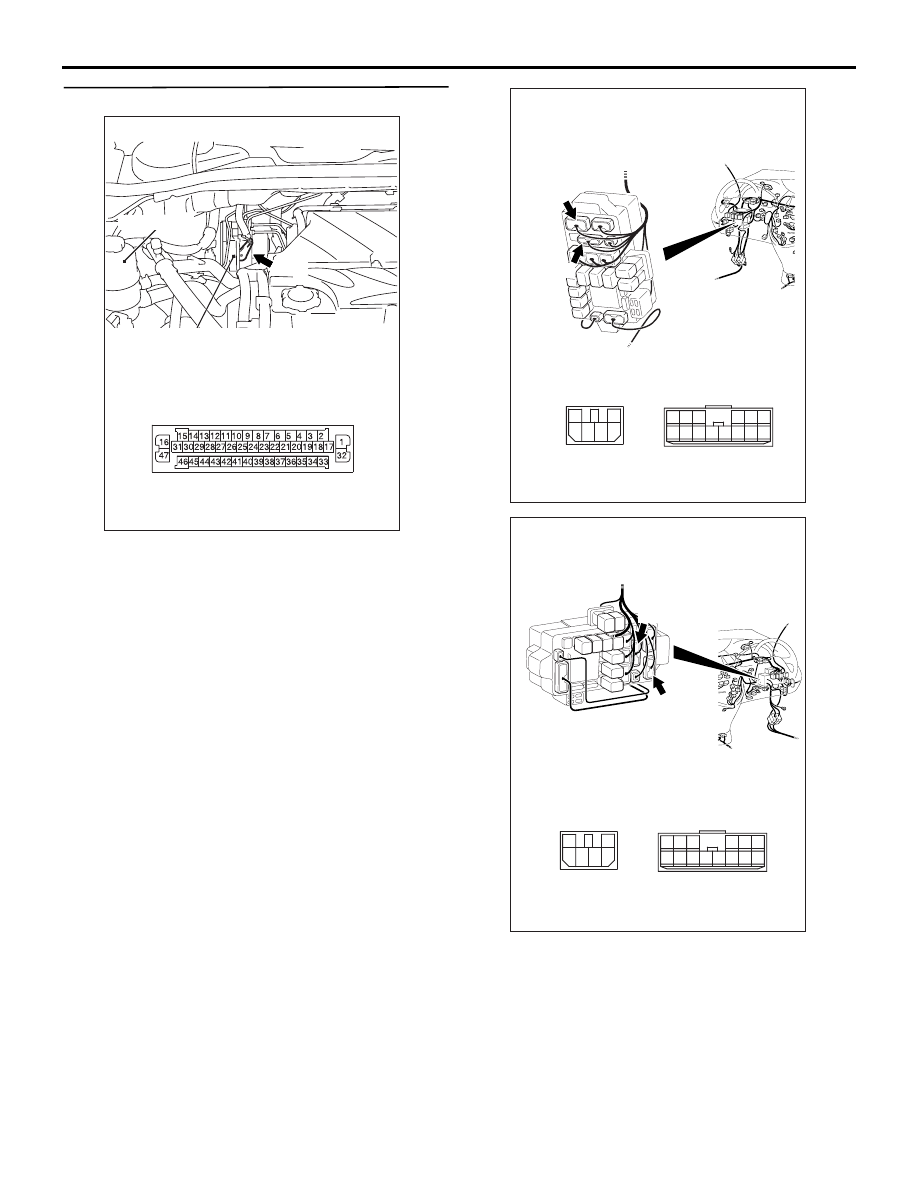

STEP 6. Check the following connectors.

•

TCL/ASC-ECU connector A-04

•

Junction block connectors C-202 and C-203

AC312621

Oil reservoir

Connector: A-04

AB

A-04

Hydraulic unit

(with built-in TCL/ASC-ECU)

A-04 Harness connector

(harness side)

AC313139

AB

C-203

Connectors: C-202, C-203

<L.H.drive vehicles>

C-202

C-202

C-203

1

3 4

2

6

5

6

1

7

2

9

8

10

3

5

12

11

4

1314

Junction block

(Front view)

AC313140

AB

C-203

Connectors: C-202, C-203

<R.H.drive vehicles>

C-202

C-202

C-203

1

3 4

2

6

5

6

1

7

2

9

8

10

3

5

12

11

4

1314

Junction block

(Front view)