Mitsubishi Grandis. Manual - part 890

GENERAL INFORMATION

BASIC BRAKE SYSTEM

35A-2

GENERAL INFORMATION

M1351000100547

The brake system has been designed to give greater

reliability and durability and to provide excellent

braking performance.

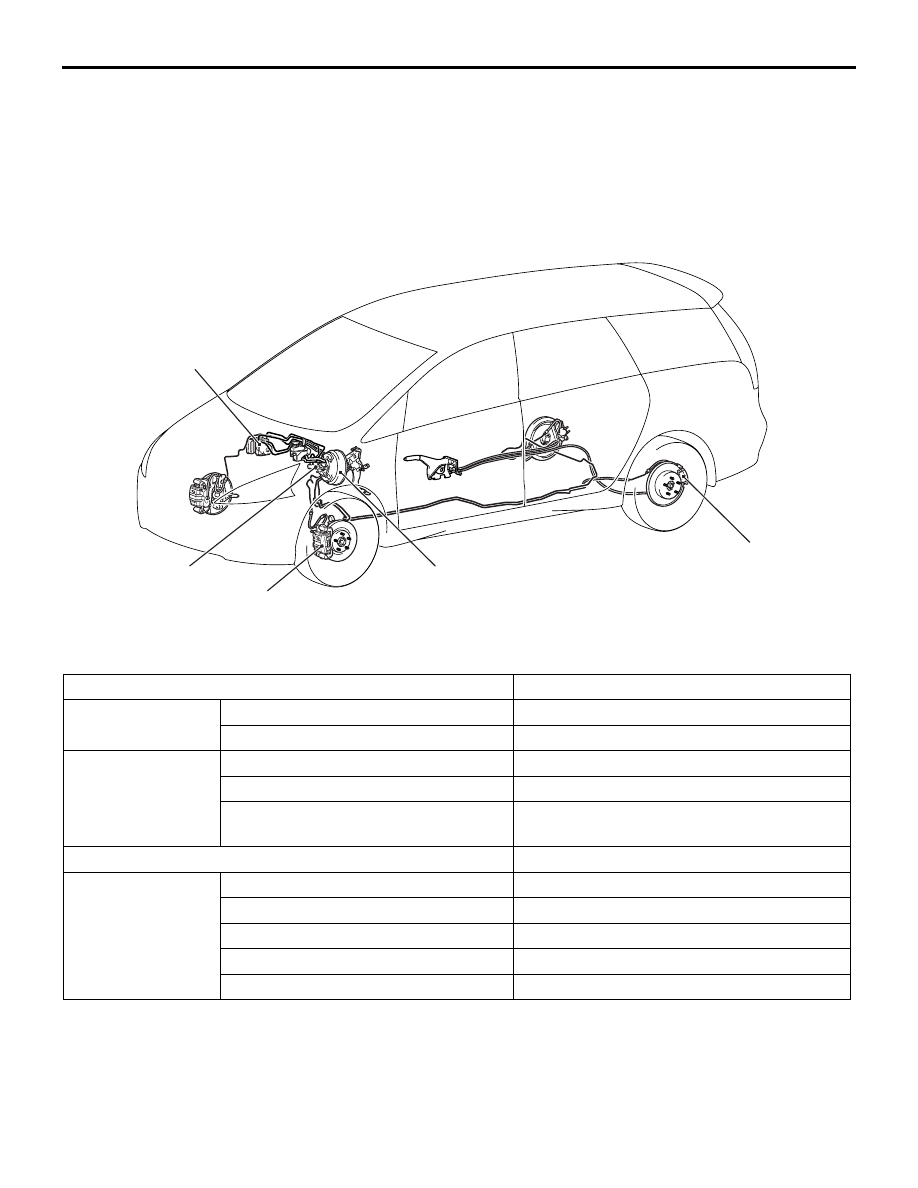

CONFIGURATION DIAGRAM

SPECIFICATIONS

AC312153

Brake booster

Rear disc brake

Master cylinder

Front disc brake

Hydraulic unit

AC

Item

Specification

Master cylinder

Type

Tandem type

I.D. mm

25.4

Brake booster

Type

Vacuum type, tandem

Effective dia. of power cylinder mm

205 + 230

Boosting ratio

8.5 (pedal pressure: 60 N)

10.5 (pedal pressure: 110 N)

Rear wheel hydraulic control method

Electronic brake-force distribution (EBD)

Front brakes

Type

Floating caliper, 2 piston, ventilated disc

Disc effective dia.

× thickness mm

241

× 26

Wheel cylinder I.D. mm

45.4

× 2

Pad thickness mm

10.0

Clearance adjustment

Automatic