Mitsubishi Grandis. Manual - part 835

TROUBLESHOOTING <A/T>

AUTOMATIC TRANSMISSION (FF)

23A-7

TROUBLESHOOTING <A/T>

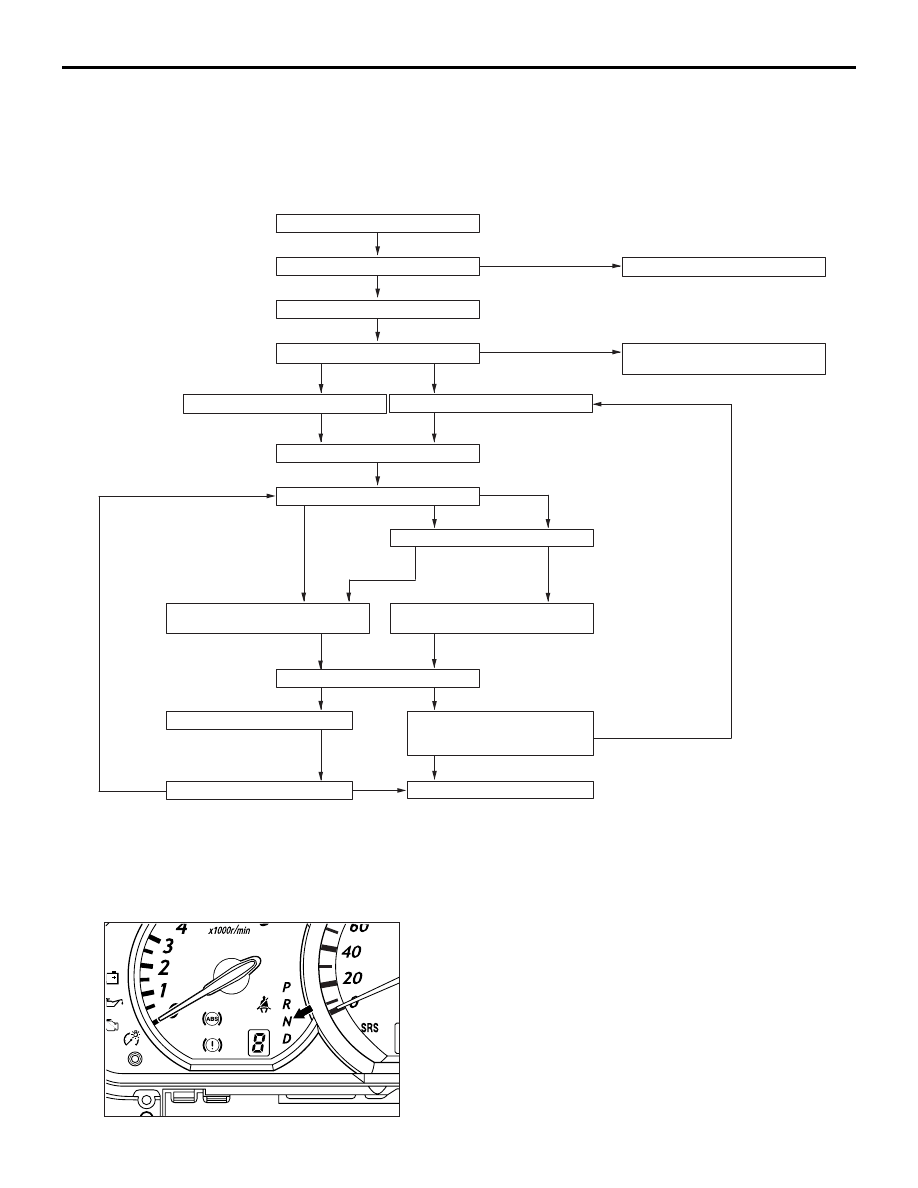

STANDARD FLOW OF DIAGNOSIS

TROUBLESHOOTING

M1231013500472

DIAGNOSIS FUNCTION

M1231019000237

N RANGE LAMP SYSTEM

If there is a problem with any of the A/T system, the

N range lamp will flash at a rate of approximately

once per second.

If the N range lamp is flashing at a rate of

approximately once per second, check the diagnosis

output.

N range lamp flashing item

• Input shaft speed sensor system

• Output shaft speed sensor system

• Solenoid valve system

• Non-synchronization at various shift ranges

• A/T control relay system

Ask about trouble symptoms

Check the A/T fluid

Check the trouble symptoms

Replace the A/T fluid

To INSPECTION CHART FOR

TROUBLE SYMPTOMS

Reading of a diagnosis code

Erase of a diagnosis code

Check the trouble symptoms

Inhibitor switch, TPS check

Road test

Recheck diagnosis codes

To INSPECTION CHART FOR

DIAGNOSIS CODES

To INSPECTION CHART FOR

TROUBLE SYMPTOMS

Check for the cause

Repair

Confirmation test (road test)

INTERMITTENT MALFUNCTIONS

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunction)

Completed

NG

OK

Communication with the

MUT-II not possible

Diagnosis code output

exists

No diagnosis code output

Abnormality exists (no diagnosis code output)

Abnormality exists

(diagnostic trouble

code output)

No abnormality

Found

Not found

OK

OK

NG

AC212495

NG

Diagnosis code output

exists

No diagnosis code output

Communication with the

MUT-III not possible

AC311593AB