Mitsubishi Grandis. Manual - part 722

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI)

13A-139

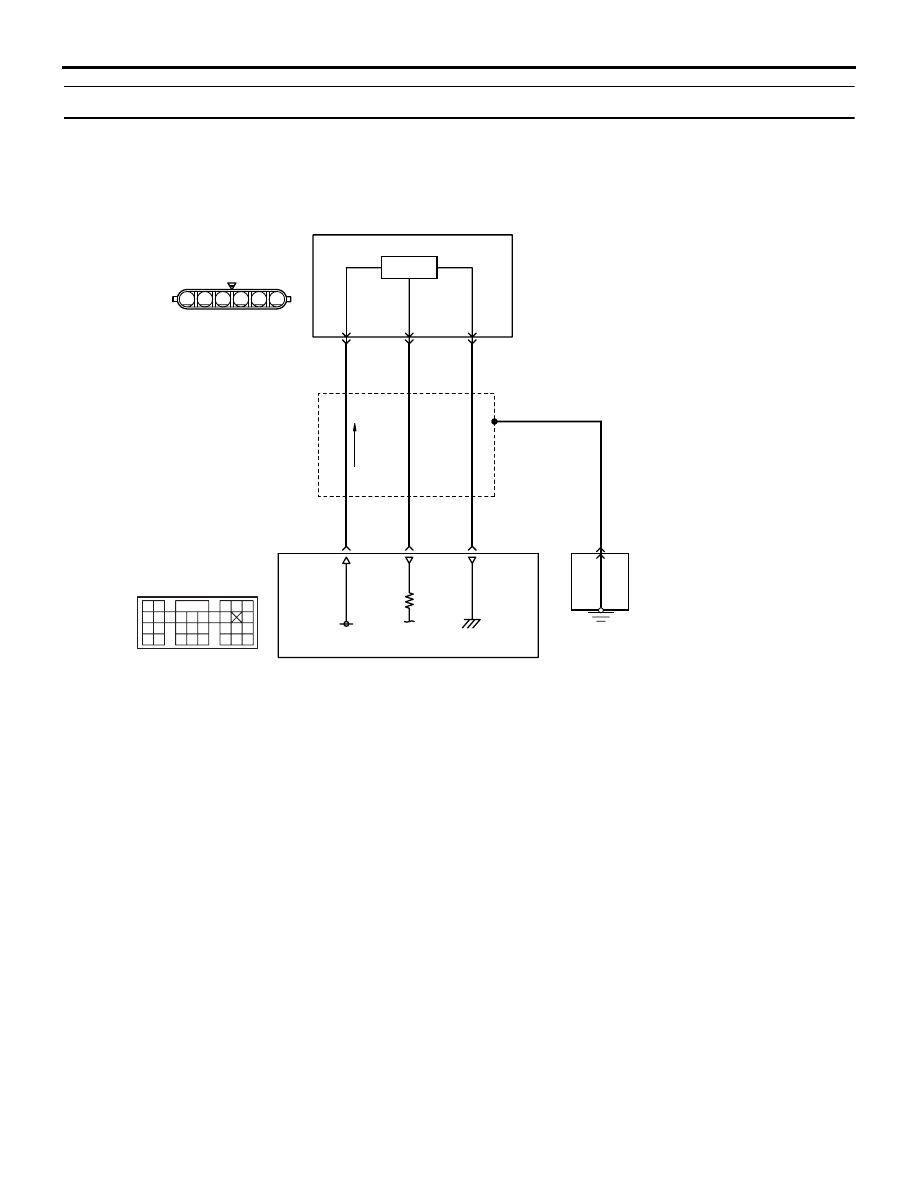

Code No. P0223: Throttle Position Sensor (Sub) Circuit High Input

OPERATION

• A power voltage of 5 V is applied to the

electronic-controlled throttle valve (terminal No.

5) from the engine-ECU <M/T> or

engine-A/T-ECU <A/T> (terminal No. 106).

• The power voltage is earthed to the engine-ECU

<M/T> or engine-A/T-ECU <A/T> (terminal No.

105) from the electronic-controlled throttle valve

(terminal No. 3).

• The sensor signal is inputted to the engine-ECU

<M/T> or engine-A/T-ECU <A/T> (terminal No.

113) from the electronic-controlled throttle valve

output terminal (terminal No. 6).

FUNCTION

• The throttle position sensor converts the throttle

valve position into voltage and inputs it into the

engine-ECU <M/T> or engine-A/T-ECU <A/T>.

• The engine-ECU <M/T> or engine-A/T-ECU

<A/T> controls the throttle valve position.

TROUBLE JUDGMENT

Check Condition

• Ignition switch is in "ON" position.

Judgment Criterion

• Throttle position sensor (sub) output voltage is

4.8 V or more for 0.5 second.

PROBABLE CAUSE

• Failed throttle position sensor (sub)

AK305560

6

1 2 3 4 5

9192

939495

96979899

100

105

113114

115116117

118119120

106

107108109

110111112

101102103

104

(sub)

Hall IC

AB

5 V

106

5

B

C-115

W

B

R

Engine-ECU <M/T> or

engine-A/T-ECU <A/T>

113

105

7

6

3

Throttle position sensor (sub) circuit

B-06

C-113

(MU803805)

Wire colour code

B: Black LG: Light green G: Green L: Blue W: White Y: Yellow SB: Sky blue BR: Brown O: Orange GR: Gray

R: Red P: Pink V: Violet

Electronic-controlled

throttle valve