Mitsubishi Grandis. Manual - part 653

TORQUE SPECIFICATIONS

ENGINE OVERHAUL

11B-7

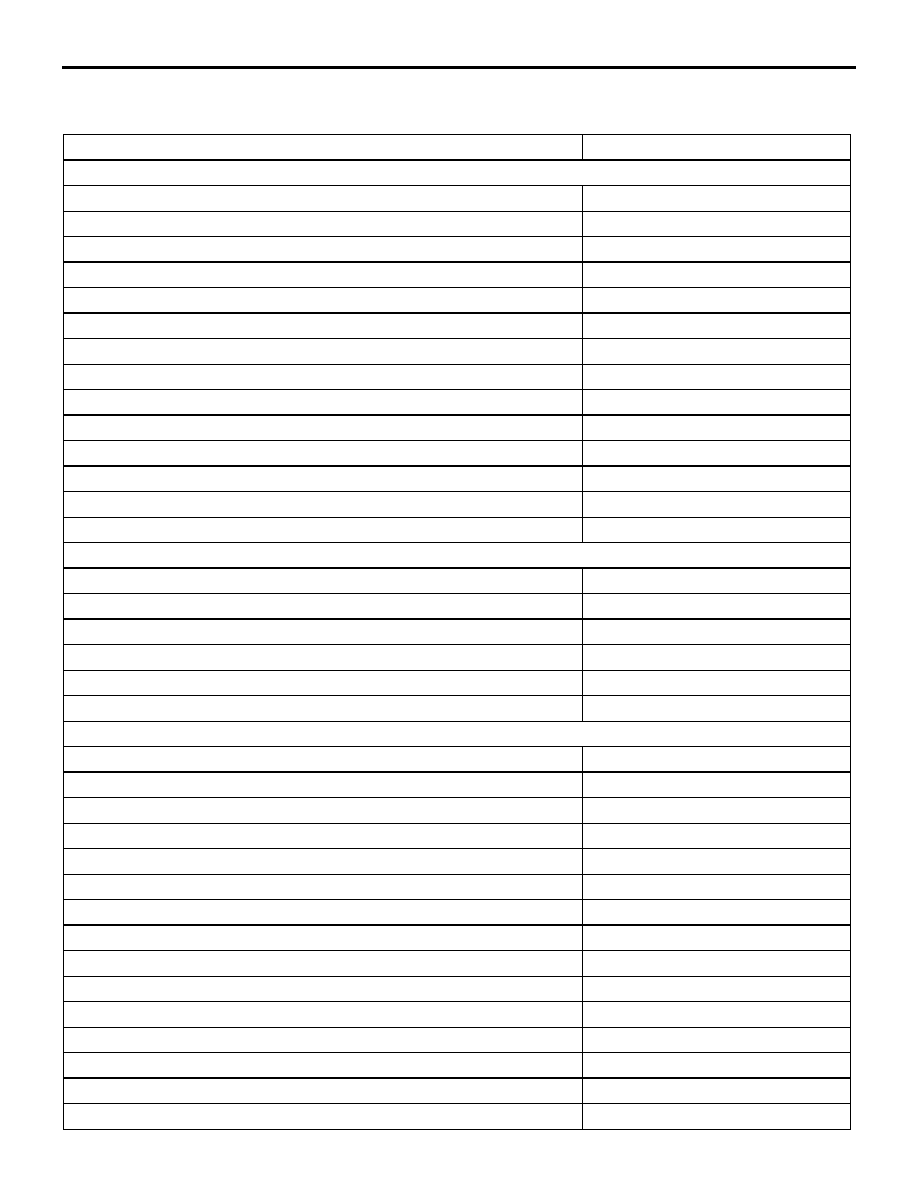

TORQUE SPECIFICATIONS

M1113023400785

Item

Specification

Alternator and ignition system

Auto-tensioner bracket bolt M10

44

± 10 N⋅m

Auto-tensioner bracket bolt M8

22

± 4 N⋅m

Camshaft position sensing cylinder bolt

22

± 4 N⋅m

Camshaft position sensor bolt

10

± 2 N⋅m

Camshaft position sensor support bolts

14

± 1 N⋅m

Connector bracket bolts

10

± 1 N⋅m

Crankshaft pulley bolts

25

± 4 N⋅m

Alternator bolt

49

± 9 N⋅m

Alternator pivot nut

44

± 10 N⋅m

Idler pulley bolt

79

± 5 N⋅m

Ignition coil bolts

10

± 2 N⋅m

Oil level gauge guide bolts

13

± 1 N⋅m

Spark plugs

25

± 5 N⋅m

Water pump pulley bolts

8.8

± 1.0 N⋅m

Exhaust manifold

Oxygen sensors

44

± 5 N⋅m

Engine hanger bolt

24

± 3 N⋅m

Exhaust manifold cover bolts

14

± 1 N⋅m

Exhaust manifold bracket B bolt

44

± 5 N⋅m

Exhaust manifold nuts

49

± 5 N⋅m

Exhaust manifold bracket A bolts

36

± 5 N⋅m

Timing belt

Auto-tensioner bolts

23

± 2 N⋅m

Camshaft sprocket bolt

89

± 9 N⋅m

Counterbalance shaft sprocket bolt

45

± 3 N⋅m

Crankshaft bolt

167 N

⋅m

Crankshaft angle sensor bolts

8.5

± 0.5 N⋅m

Engine support bracket bolts

49

± 5 N⋅m

Alternator bracket bolts

49

± 9 N⋅m

Idler pulley bolt

35

± 6 N⋅m

Oil pump sprocket nut

54

± 4 N⋅m

Tensioner "B" bolt

19

± 3 N⋅m

Tensioner arm bolt

21

± 4 N⋅m

Tensioner pulley bolt

48

± 5 N⋅m

Timing belt cover bolts M6 (Bolt, washer assembly)

9.0

± 1.0 N⋅m

Timing belt cover bolts M6 (Flange bolt and nut)

11

± 1 N⋅m

Timing belt cover bolts M8

14

± 1 N⋅m