Mitsubishi Grandis. Manual - part 652

HOW TO USE THIS MANUAL

ENGINE OVERHAUL

11B-3

ENGINE OVERHAUL

11-54

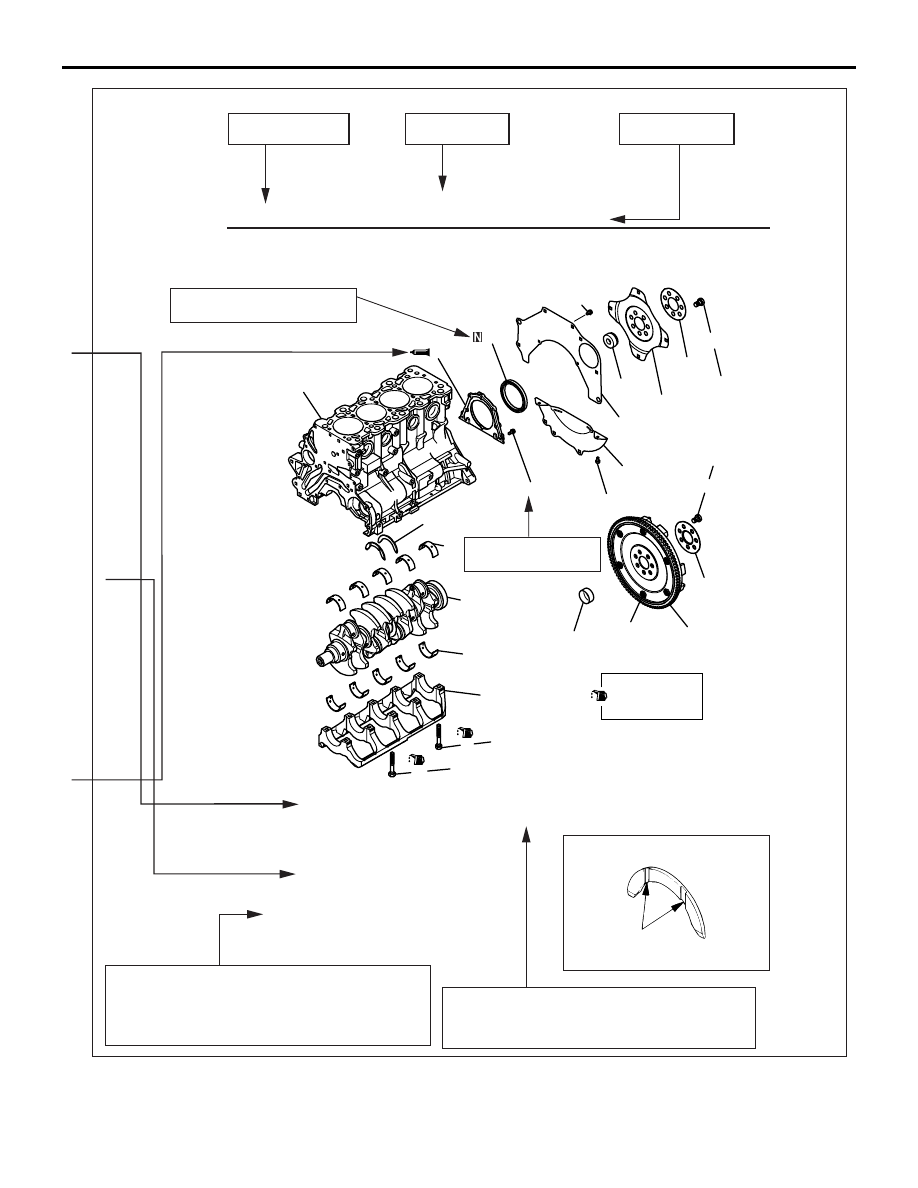

CRANKSHAFT AND CYLINDER BLOCK

REMOVAL AND INSTALLATION

Section title

Page number

Procedures and cautions for removal, instal-

lation, disassembly, and reassembly are ex-

plained under this category of heading.

The alphabetical character in this category of

heading matches that of the relevant removal

steps, installation steps, disassembly steps, or

reassembly steps.

Denotes non-reusable part.

Tightening torque

CRANKSHAFT AND CYLINDER BLOCK

Removal steps

1.

Flywheel bolt

2. Adapter plate

3.

Flywheel

4. Crankshaft bushing

5.

Drive plate bolt

6.

Adapter plate

7.

Drive plate

8.

Crankshaft bushing

9.

Rear plate

10.

Bell housing cover

>>E<< 11.

Oil seal case

>>D<< 12.

Oil seal

>>A<< THRUST BEARING INSTALLATION

INSTALLATION SERVICE POINTS

AK100786AB

Grooves

Group title

AK303970

AK303794AB

6

7

8

9

10

11

12

14

13

15

16

17

18

19

20

11 ± 1 N·m

132 ± 5 N·m

25 ± 2 N·m

Apply engine oil

to all moving

parts before

installation.

5

9.0 ± 1.0 N·m

11 ± 1 N·m

→ + 90˚

25 ± 2 N·m

→ + 90˚

1

3

A

4

2

132 ± 5 N·m