Mitsubishi Grandis. Manual - part 638

CYLINDER HEAD GASKET

ENGINE MECHANICAL

11A-29

REMOVAL SERVICE POINTS

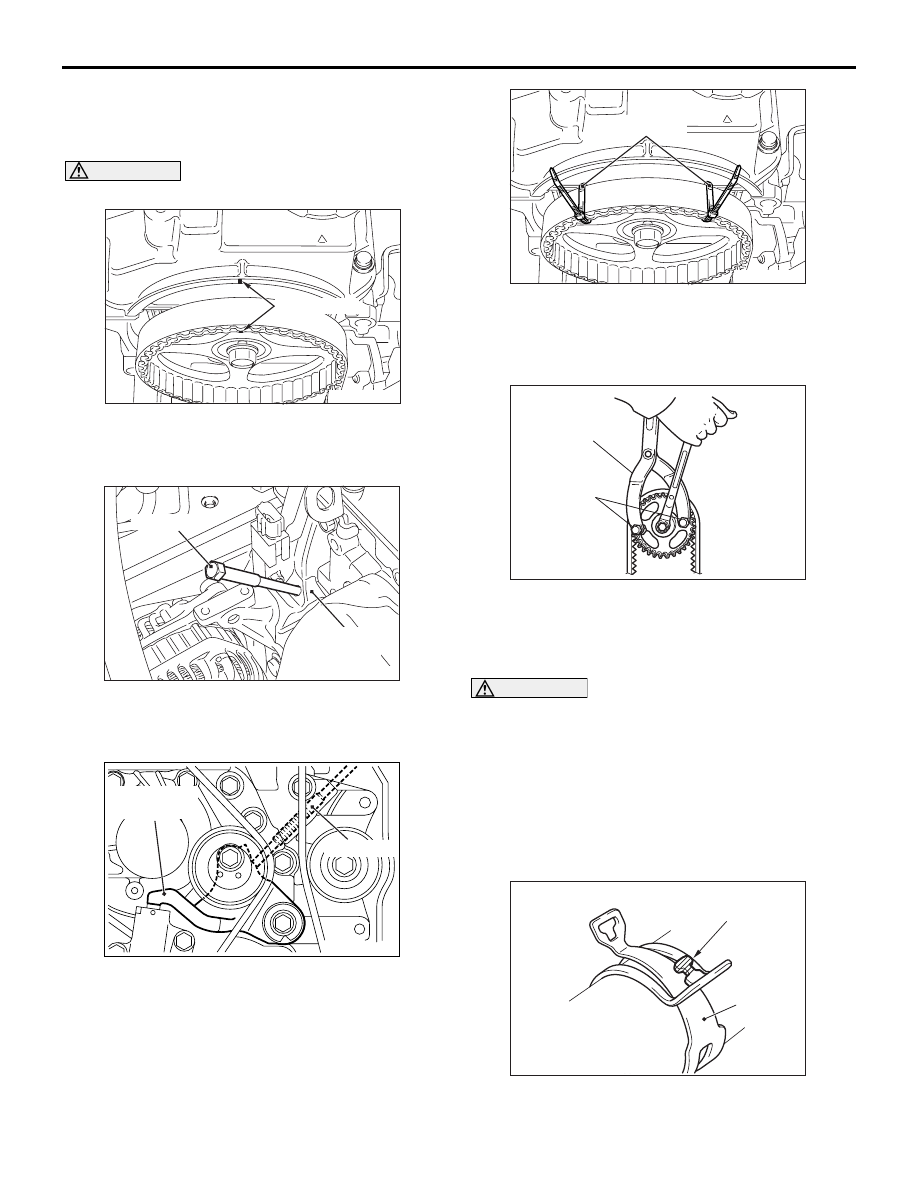

<<A>> CAMSHAFT SPROCKET

REMOVAL

CAUTION

Never turn the crankshaft anti-clockwise.

1. Turn the crankshaft clockwise, align the timing

marks on the camshaft sprocket to set No.1

cylinder to TDC of its compression stroke.

2. Remove the timing belt under cover rubber plug

and then set special tool adjusting bolt

(MD998738).

3. Screw in the special tool until it comes in contact

with the timing belt tensioner arm.

4. Secure the camshaft sprocket and valve timing

belt with wiring bands and so on to prevent

slippage between the camshaft sprocket and

valve timing belt.

5. Use the following special tools to hold the

camshaft sprocket.

• Front hub and flange yoke holder (MB990767)

• Pin (MD998719)

CAUTION

Do not rotate the crankshaft after camshaft

sprocket removal.

6. Remove the camshaft sprocket with the valve

timing belt and place it on the timing belt lower

cover.

<<B>> RADIATOR UPPER HOSE/HOSE

CLIP DISCONNECTION

Break off the tip of hose clip claw and spread out the

hose clip, then disconnect the radiator upper hose.

NOTE: If there is a hose clip claw, the hose clip

cannot spread to capacity.

AC301450AB

Timing mark

AC301452AB

MD998738

Timing belt

under cover

AC301373

AB

MD998738

Timing belt

tensioner arm

AC107621

AC301451AC

Wiring band

AC100302

MD998719

MB990767

AB

AC302615

Hose clip

Claw (Tip)

AE