Mitsubishi Grandis. Manual - part 537

DIAGNOSIS

CONTROLLER AREA NETWORK (CAN)

54D-246

harness side.

CAUTION

When measuring the resistance, disconnect the

negative battery terminal. For details refer to

(2) Ensure that the negative battery terminal is

disconnected.

(3) Resistance between C-09 joint connector (CAN2)

terminal No.19 and body earth

OK: 1 k

Ω or more

CAUTION

Strictly observe the specified wiring harness

repair procedure. For details refer to

Q: Is the check result normal?

YES :

<less than 1.0 V> Follow diagnostic item 19

"Diagnose CAN bus lines thoroughly." Refer

to

NO :

<1.0 V or more> Repair the wiring harness

between the joint connector (CAN2) and the

A/C-ECU connector.

STEP 10. Connector check: C-221 ETACS-ECU

connector

CAUTION

The strand end of the twist wire should be within

10 cm from the connector. For details refer to

Q: Is the check result normal?

YES :

Go to Step 11.

NO :

Repair the defective connector.

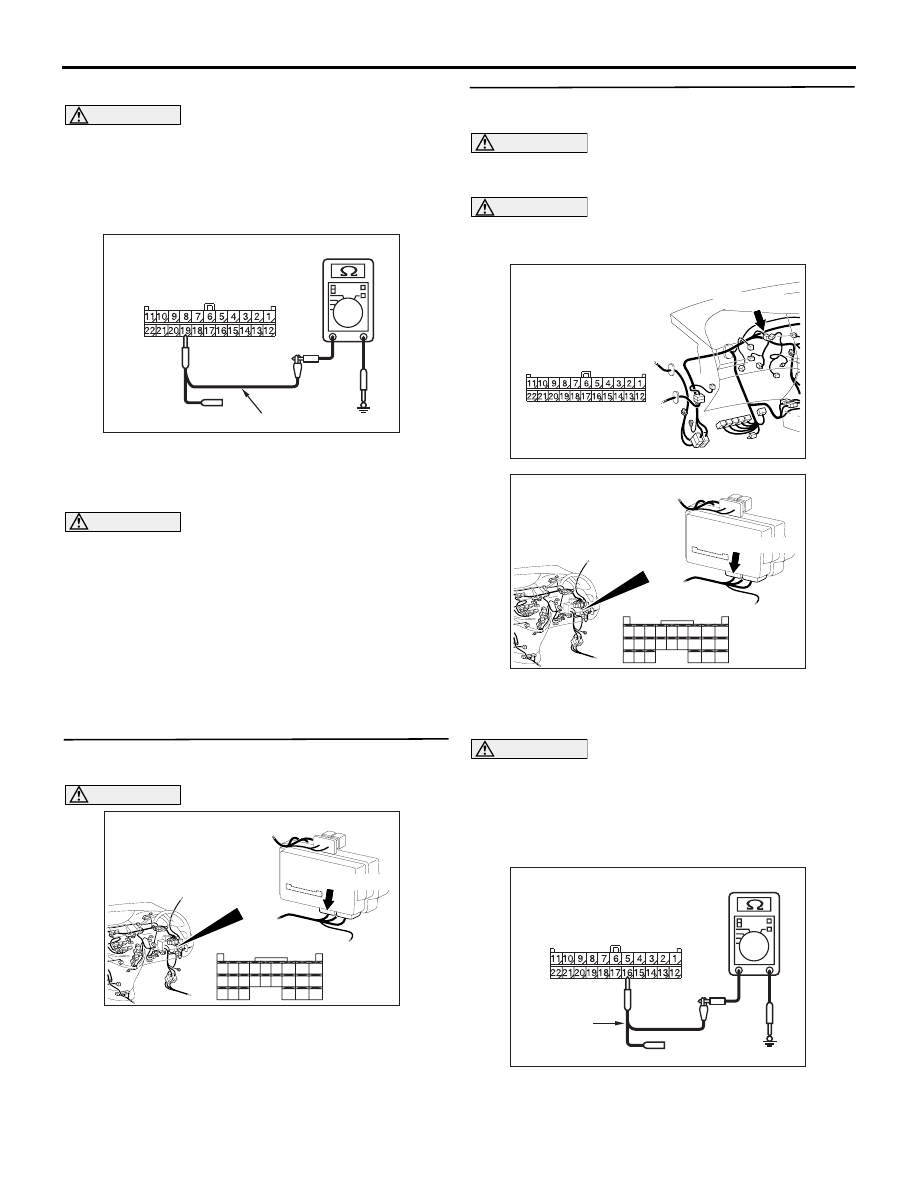

STEP 11. Resistance measurement at C-09 joint

connector (CAN2).

CAUTION

A digital multimeter should be used. For details

refer to

.

CAUTION

The test wiring harness should be used. For

details refer to

(1) Disconnect the joint connector (CAN2) and the

ETACS-ECU connector, and measure at the

wiring harness side.

CAUTION

When measuring the resistance, disconnect the

negative battery terminal. For details refer to

(2) Ensure that the negative battery terminal is

disconnected.

(3) Resistance between C-09 joint connector (CAN2)

AC209364LF

Harness side: C-09

Test harness

AC310620

Connector: C-221

Junction block

(Rear view)

<RHD>

AC

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

Harness side

C-221(GR)

AC310628AY

Connector: C-09 <RHD>

C-09 (GR)

Harness side

AC310620

Connector: C-221

Junction block

(Rear view)

<RHD>

AC

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

Harness side

C-221(GR)

AC209364MF

Harness side: C-09

Test

harness