Mitsubishi Grandis. Manual - part 259

INPUT SIGNAL PROCEDURES

SMART WIRING SYSTEM (SWS) USING SWS MONITOR

54C-498

COMMENTS ON TROUBLE SYMPTOM

Input signal from the hazard warning lamp switch is

used to operate the functions below. If the signal is

abnormal, these functions will not work normally.

• Turn-signal lamp operation sound

• Keyless entry system (encrypted code

registration)

• Keyless entry hazard answerback

• Hazard warning lamp

POSSIBLE CAUSES

• Malfunction of the hazard warning lamp switch

• Malfunction of the ETACS-ECU

• Damaged harness wires and connectors

DIAGNOSIS PROCEDURE

Step 1. Connector check: C-123 hazard warning

lamp switch connector

Q: Is the check result normal?

YES :

Go to Step 2.

NO :

Repair the defective connector.

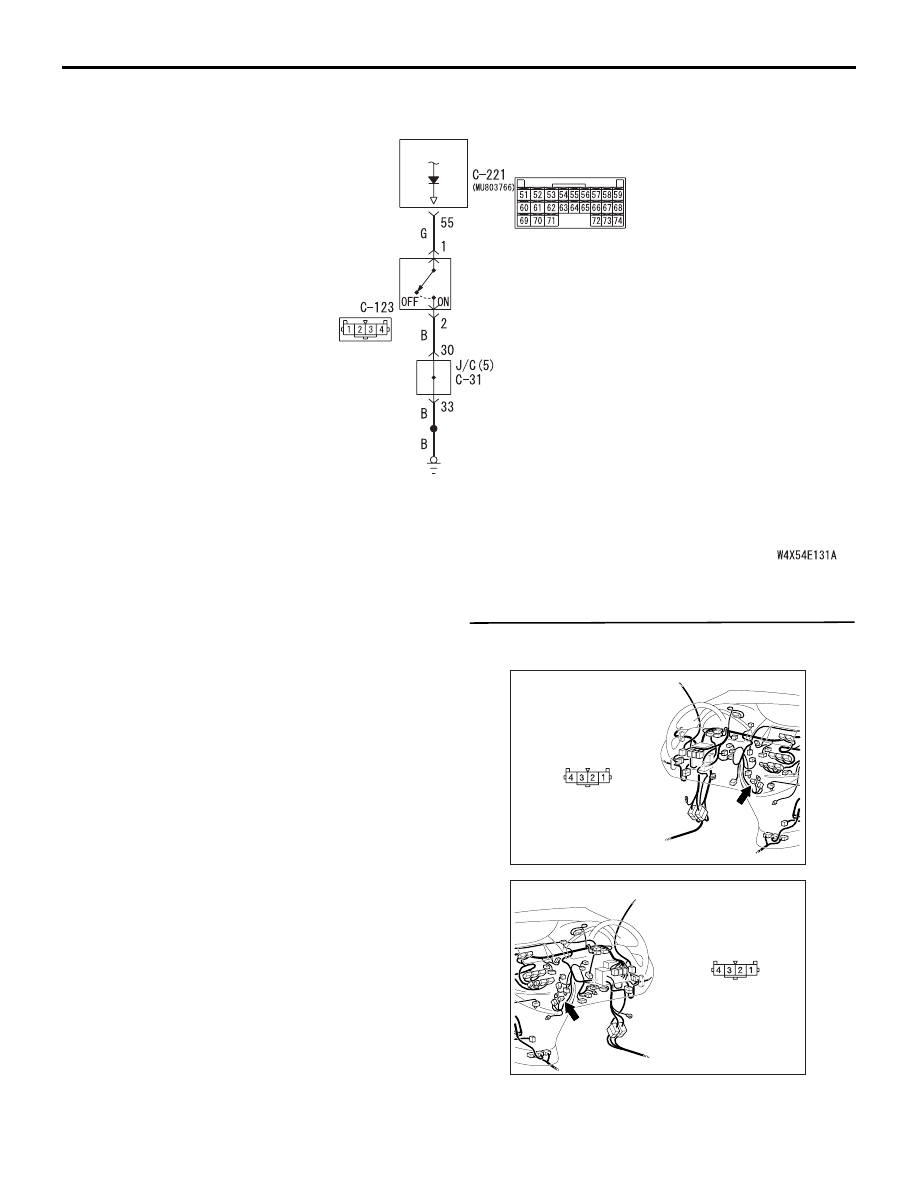

ETACS-

ECU

HAZARD

WARNING

LAMP SWITCH

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

Hazard Warning Lamp Switch Input Circuit <RHD>

AC312031

AD

Connector: C-123 <LHD>

Harness side

AC312043AD

Connector: C-123 <RHD>

Harness side