Mitsubishi L200. Manual - part 680

COMBINATION METER

CHASSIS ELECTRICAL

54A-87

ON-VEHICLE SERVICE

CHECK THE SPEEDOMETER

M1540201400608

CAUTION

Since the diagnosis code may be stored in the

ABS-ECU or ASTC-ECU when checking the

speedometer with speedometer tester, erase the

diagnosis code.

CAUTION

Do not accelerate or decelerate suddenly during

servicing work.

1. Check that the current tyre inflation pressures

meet the inflation pressure label (Refer to

GROUP 31

− On-vehicle Service ).

2. Move <4WD> transfer shift lever to "4H" position.

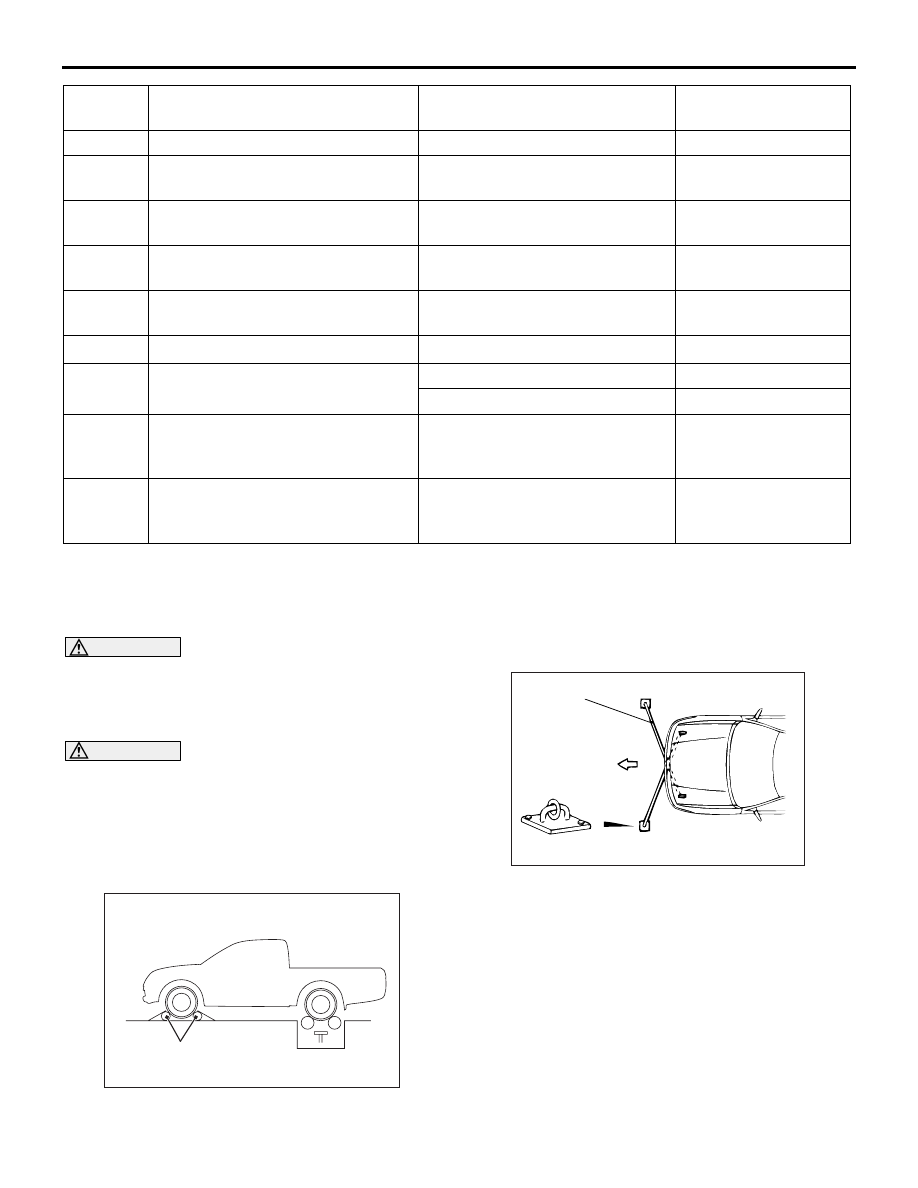

3. Set the vehicle on the speedometer tester and set

the front wheels on the free roller.

4. For prevention of front wheel lateral runout, install

chain or wire (the other end of which is tightly

fixed on front towing hooks) on the vehicle.

5. For prevention of rear wheel lateral runout and of

vehicle from starting out, install extension fittings

on rear towing hooks, and install both ends in the

anchor plate.

6. Check that the speedometer indicating range is

within the standard value and the needle

fluctuation is within the limit.

Standard value <Speedometer to display km/

h only>:

15

Illumination (earth)

Always

1 V or less

16

Illumination (power supply)

Illumination switch: ON and

lighting switch: ON

System voltage

17

Brake warning lamp

Ignition switch: ON and brake

warning lamp: ON

System voltage

18

SRS air bag warning lamp

Ignition switch: ON and SRS air

bag warning lamp: ON

System voltage

19

ABS warning lamp

Ignition switch: ON and ABS

warning lamp: ON

System voltage

20, 21

−

−

−

22

Input of fuel gauge

Fuel: FULL

Approximately 2 V

Fuel: EMPTY

Approximately 8 V

23

Input of turn-signal lamp RH switch Ignition switch: ON and turn-

signal lamp (RH) switch: ON and

turn-signal lamp: ON (turn: ON)

System voltage

24

Input of high beam switch

Ignition switch: ON and high

beam switch: ON and high beam

indicator: ON (beam: ON)

System voltage

Terminal

No.

Check items

Check conditions

Normal conditions

AC802659AB

Free roller

AC001288

Tension bar

Front

Anchor plate

AB