Mitsubishi L200. Manual - part 393

REAR DIFFERENTIAL LOCK <4WD>

REAR AXLE

27-23

REAR DIFFERENTIAL LOCK AIR PUMP

CHECK

M1272003100038

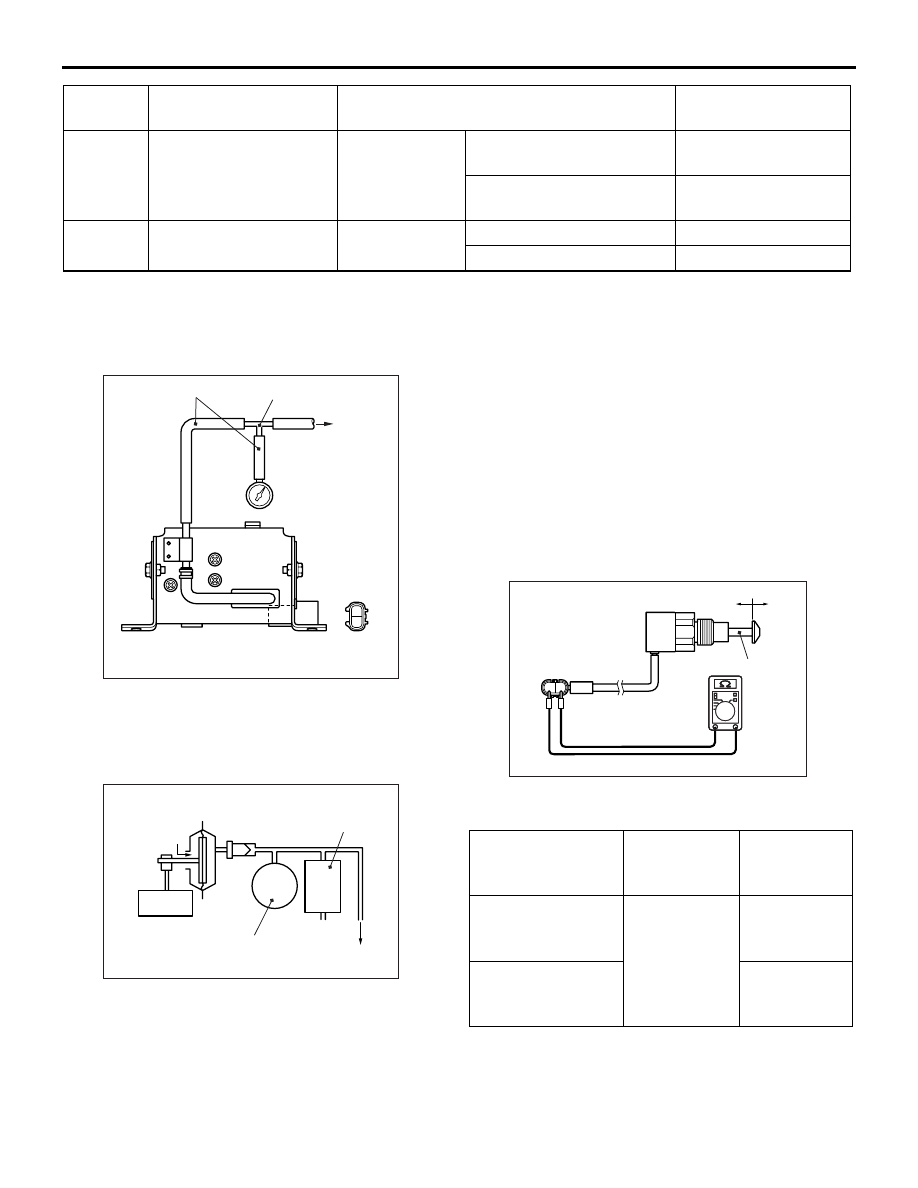

1. Install the air hose to the differential.

1

2

AC508812AB

Air hose

T-joint

Pressure

gauge

Battery (-)

Battery (+)

Differential

2. Connect a pressure gauge to the air pump

discharge outlet nozzle, via the air hose and T-

joint.

3. Apply battery voltage to the air pump connector.

AC508813AB

Differential

Release

valve

Pressure

switch

Motor

Atmosphere

4. Measure the time when the pump starts and stops

operating, and if it stops within 5 seconds, the

pressure switch inside the pump is normal.

5. Measure the pressure 10

− 20 seconds after the

pump has stopped.

Standard value: 24.5

− 39 kPa (-30 − 0°C),

24.5

− 34 kPa (0 − 100°C)

6. If the pressure is within the standard value, the

release valve inside the pump is normal.

7. Check the pump does not begin operating for 5

minutes after it has stopped.

8. If the inspection for steps 4-7 is normal, the pump

is fully operational.

REAR DIFFERENTIAL LOCK DETECTION

SWITCH CHECK

M1272001000057

2

1

AC711365AB

Rod

ON

OFF

Check for continuity between the terminals of the

switch.

Measurement

condition

Terminal

connector of

tester

Specified

condition

When the rod is

pulled

1 - 2

Continuity

(less than 2

Ω)

When the rod is

returned to its

normal position

Open circuit

1

Rear differential lock

switch (OFF position)

Ignition switch:

ON

Rear differential lock switch

is pushed.

1 V or less

Rear differential lock switch

is not pushed.

System voltage

10

Rear differential lock

indicator lamp

Ignition switch:

ON

Rear differential is locked

1 V or less

Rear differential is free

System voltage

Terminal

No.

Item

Condition

Terminal voltage