Mitsubishi L200. Manual - part 363

Disassembly steps

>>D<<

1.

Snap ring

>>C<<

2.

Reaction plate

>>C<<

3.

Clutch disc

>>C<<

4.

Clutch plate

<<A>>

>>B<<

5.

Snap ring

6.

Spring retainer

>>A<<

7.

D-ring

8.

Return spring

9.

Direct clutch piston

>>A<<

10. D-ring

>>A<<

11. D-ring

12. Direct clutch retainer

DIRECT CLUTCH

AUTOMATIC TRANSMISSION OVERHAUL <V5A5>

23D-67

DISASSEMBLY SERVICE POINT

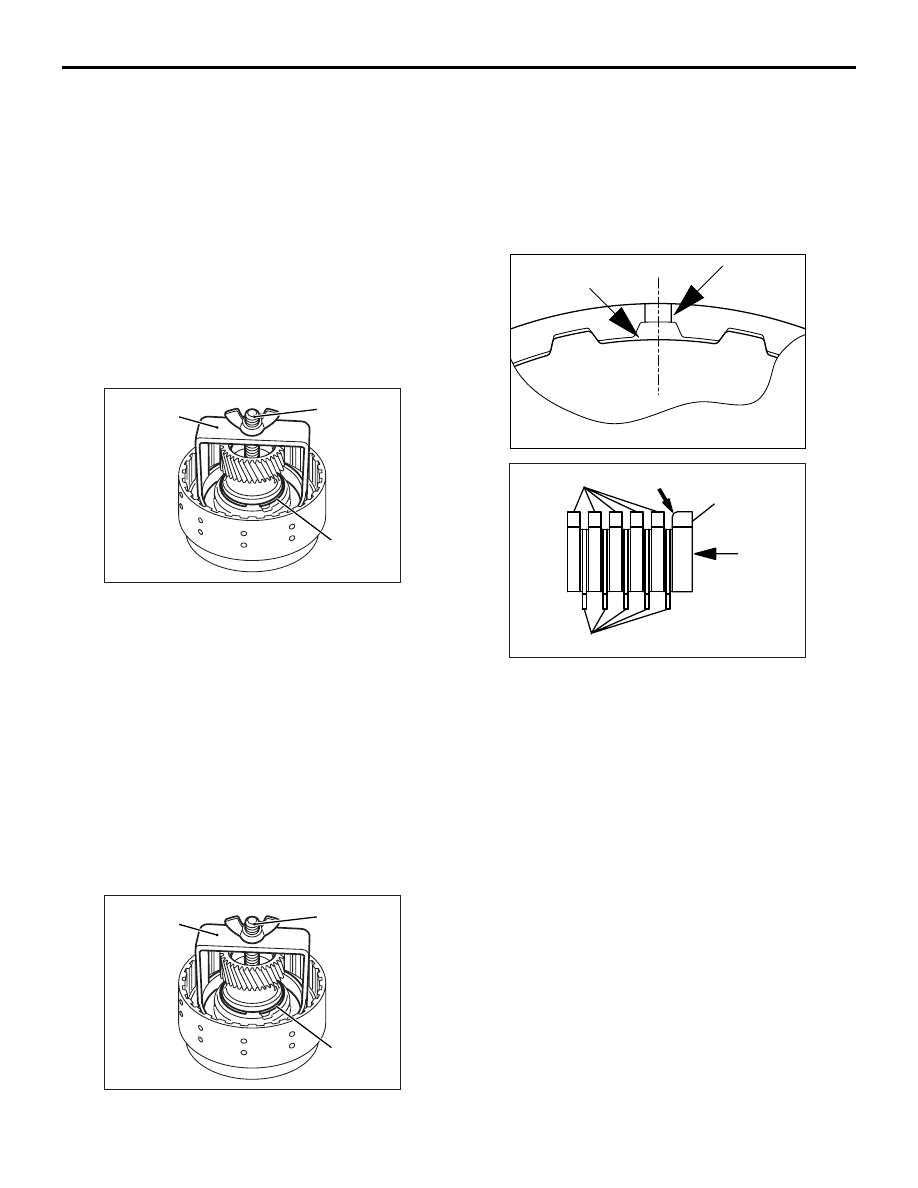

<<A>> SNAP RING REMOVAL

AK602068AC

MB991630

MD998924

Sanp ring

1. Set the special tools as shown in the illustration.

• Spring compressor (MB991630)

• Spring compressor retainer (MD998924)

2. Compress the return spring, and remove the snap

ring.

REASSEMBLY SERVICE POINTS

>>A<< D-RING INSTALLATION

1. Apply ATF to the D-ring.

2. Install the D-ring in the direct clutch piston and

spring retainer groove. Make sure that the D-ring

is not twisted or damaged when installing.

>>B<< SNAP RING INSTALLATION

AK602068AC

MB991630

MD998924

Sanp ring

1. Set the special tools as shown in the illustration.

• Spring compressor (MB991630)

• Spring compressor retainer (MD998924)

2. Compress the return spring, and install the snap

ring.

>>C<< CLUTCH PLATE / CLUTCH DISC /

REACTION PLATE INSTALLATION

AK602069

B

A

AC

AK602070

R Stamp

AC

Clutch plates

Reaction plate

Clutch discs

Rounded edge

1. Alternately assemble the clutch plates and clutch

discs in the reverse clutch retainer. Align the

section having no teeth of the clutch plates (A in

the illustration) with the reverse clutch retainer

hole (B in the illustration).

2. Install the reaction plate so that it is oriented as

shown in the illustration. Assemble in the same

manner as the clutch plate so that the section with

no teeth (A in the illustration) matches the retainer

hole (B in the illustration).

>>D<< SNAP RING INSTALLATION

1. Install the snap ring in the direct clutch retainer

groove.