Mitsubishi L200. Manual - part 316

AKX00069

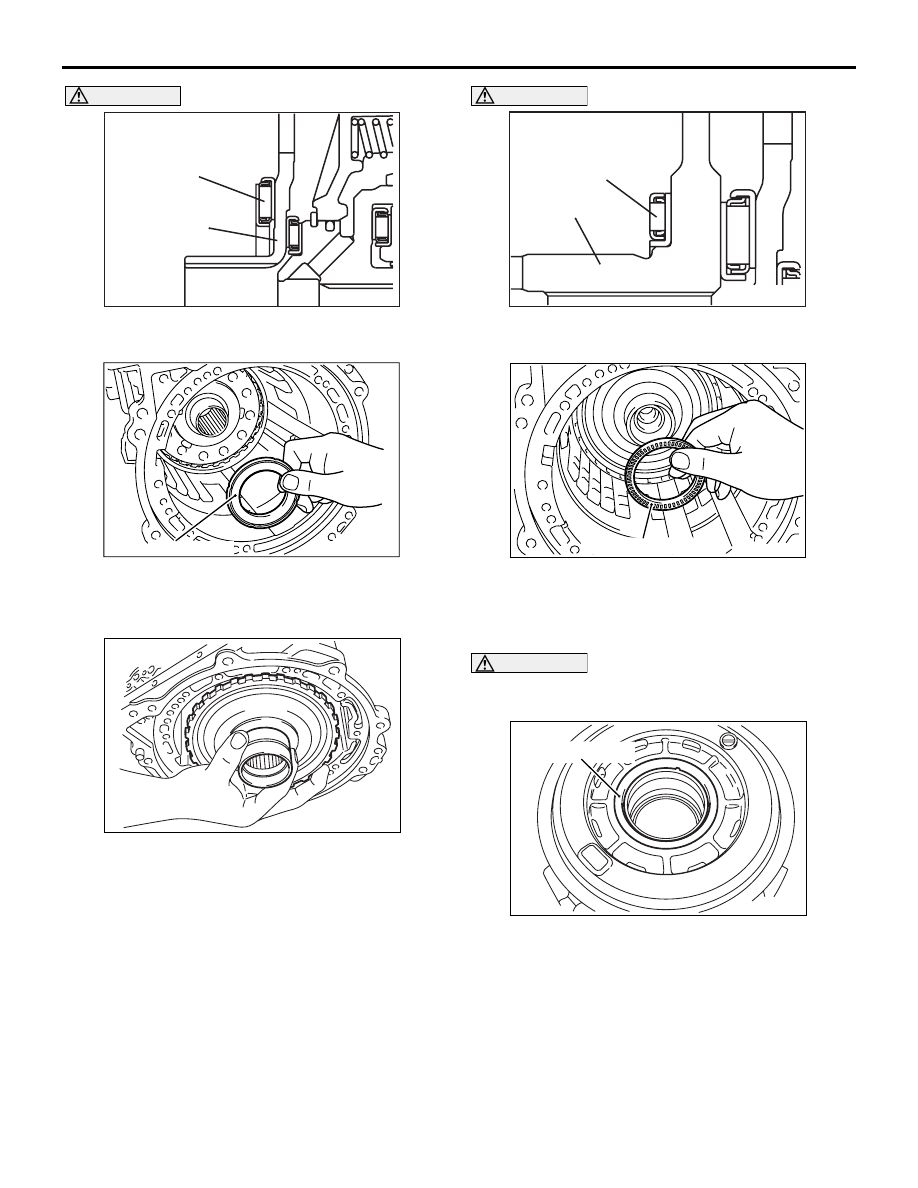

Thrust beaing No.10

Underdrive clutch

hub

AE

TRANSMISSION

AUTOMATIC TRANSMISSION OVERHAUL <R4A5>

23B-28

CAUTION

Make sure thrust bearing No.10 is mounted in the

correct direction.

AK403446

Thrust bearing

No.

10

AC

10.Apply vaseline or petroleum jelly on the thrust

bearing No.10, and then install it on the

underdrive clutch hub.

AK403447

11.Install the output flange.

AKX00072

Thrust bearing No.9

Output flange

AG

CAUTION

Make sure thrust bearing No.9 is mounted in the

correct direction.

AK403448

Thrust bearing No.9

AC

12.Apply vaseline or petroleum jelly on the thrust

bearing No.9, and then install on the output

flange.

CAUTION

Measure and record the thickness of the thrust

race No.8 to be assembled.

AK403449AD

Thrust race No.8

13.Apply vaseline or blue petroleum jelly on the

thrust race No.8 being used, and then install it on

the rear side of the center support.