Mitsubishi L200. Manual - part 252

OUTPUT SHAFT

MANUAL TRANSMISSION OVERHAUL <R5MB1>

22B-33

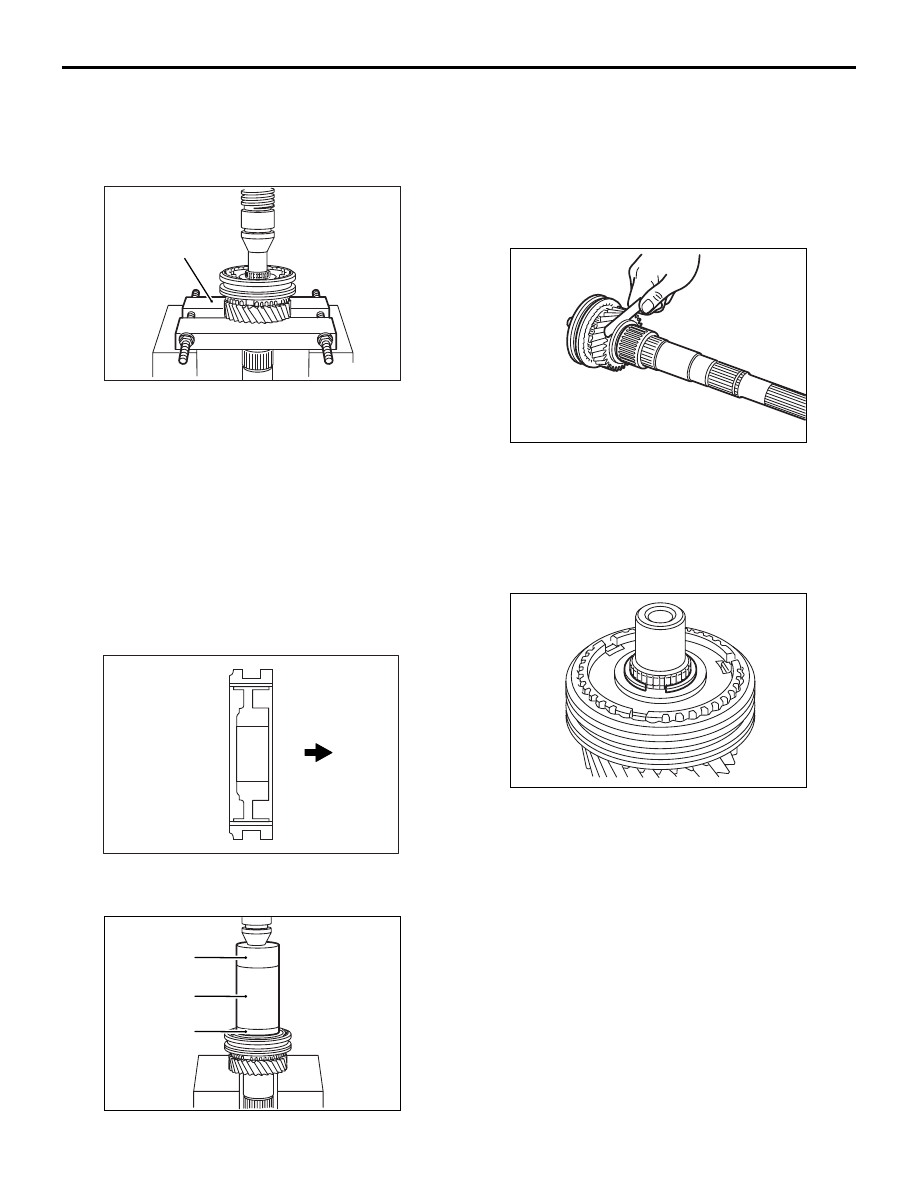

<<D>> TRANSMISSION CLUTCH HUB No.2 /

SYNCHRONIZER SHIFTING KEY No.2 /

COMPRESSION SPRING / TRANSMISSION HUB

SLEEVE No.2 / SYNCHRONIZER RING SET No.2 /

3RD GEAR SUB-ASSEMBLY REMOVAL

AK404020

MD998801

AB

Using special tool Bearing remover (MD998801),

support the 3rd gear sub-assembly and remove the

transmission clutch hub No.2, synchronizer shifting

key No.2, compression spring, the transmission hub

sleeve No.2, synchronizer ring set and the 3rd gear

sub-assembly.

REASSEMBLY SERVICE POINTS

>>A<< TRANSMISSION CLUTCH HUB No. 2 /

SYNCHRONIZER SHIFTING KEY No. 2 / COM-

PRESSION SPRING / TRANSMISSION HUB

SLEEVE No. 2 / SYNCHRONIZER RING SET No. 2

/ 3RD GEAR SUB-ASSEMBLY INSTALLATION

AK500607

Installation

direction

AB

1. Check the installation direction of the transmission

clutch hub No. 2, and put it on the output shaft.

AK404029

AC

MD998812

MD998823

MD998813

2. Using special tools to install the transmission

clutch hub No. 2, synchronizer shifting key No. 2,

compression spring, the transmission hub sleeve

No. 2, synchronizer ring set No. 2 and the 3rd

gear sub-assembly.

• Installer cap (MD998812)

• Installer-100 (MD998813)

•

AK500508

Installer adapter (48) (MD998823)

3. Confirm the thrust clearance of the 3rd gear sub-

assembly is within the standard value.

Standard value: 0.10

− 0.25 mm

Limit: 0.25 mm

>>B<< SHAFT SNAP RING INSTALLATION

AK404019

1. Select a shaft snap ring to secure the standard

clearance between the transmission clutch hub

No.2 and the output shaft.

Standard value: 0

− 0.1 mm

2. Install the selected snap ring.