Mitsubishi L200. Manual - part 250

AK500527

AB

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL <R5MB1>

22B-25

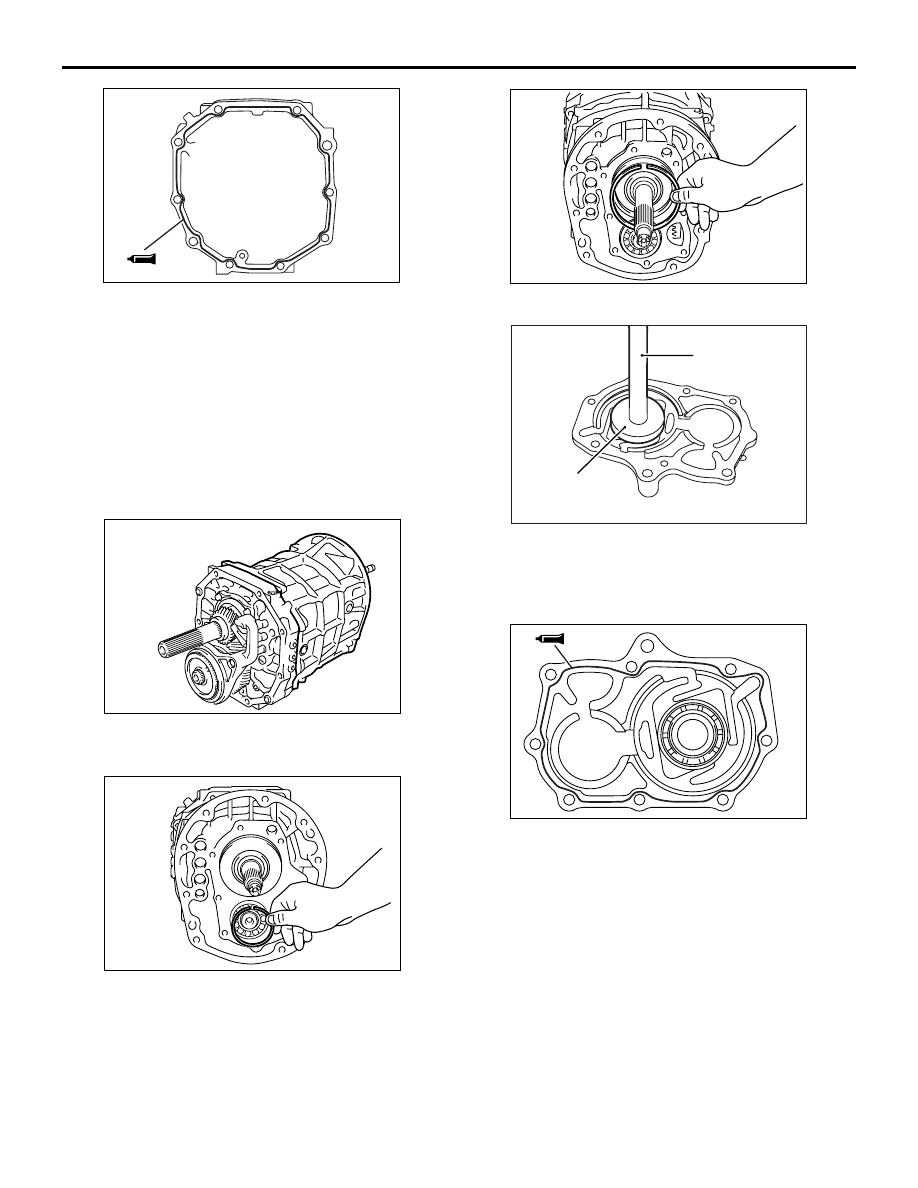

48.Completely degrease the FIPG-applied surface

so that water and oil including the old sealant

cannot adhere to the surface coated with the

sealant.

Never touch the degreased surface by hand.

49.Apply a 1.2 mm diameter bead of liquid gasket to

the intermediate plate mounting surface of the

transmission case sub-assembly.

Special sealant: Mitsubishi genuine sealant

Part No. MD974421 or equivalent

AK701366

50.Install the transmission case sub-assembly to the

intermediate plate.

AK403783

51.Install the snap ring to the cylindrical roller

bearing.

AK403782

52.Install the snap ring to the radial ball bearing.

AK600320

MB990938

MB990929

AB

53.Using special tool, install the oil seal to the front

bearing retainer.

• Installer adapter (MB990929)

•

AK403775

AB

Installer bar (MB990938)

54.Completely degrease the FIPG-applied surface

so that water and oil including the old sealant

cannot adhere to the surface coated with the

sealant.

Never touch the degreased surface by hand.

55.Apply a 1.2 mm diameter bead of liquid gasket to

the transmission case sub-assembly mounting

surface of the front bearing retainer sub-assembly

with seal.

Special sealant: Mitsubishi genuine sealant

Part No. MD974421 or equivalent