Mitsubishi L200. Manual - part 238

CLUTCH PEDAL

CLUTCH

21A-4

CLUTCH PEDAL

REMOVAL AND INSTALLATION

M1211001601008

Pre-removal Operation

• Lower Panel Assembly Removal (Refer to GROUP 52A −

Instrument Panel Assembly ).

• Drivers side under cover <Except vehicles Single cab>

Removal (Refer to GROUP 52A

− Instrument Panel

Assembly ).

• ETACS-ECU Removal. <LHD>

Post-installation Operation

• ETACS-ECU Installation. <LHD>

• Drivers side under cover <Except vehicles Single cab>

Installation (Refer to GROUP 52A

− Instrument Panel

Assembly ).

• Lower Panel Assembly Installation (Refer to GROUP 52A

− Instrument Panel Assembly ).

• Clutch Pedal Adjustment (Refer to

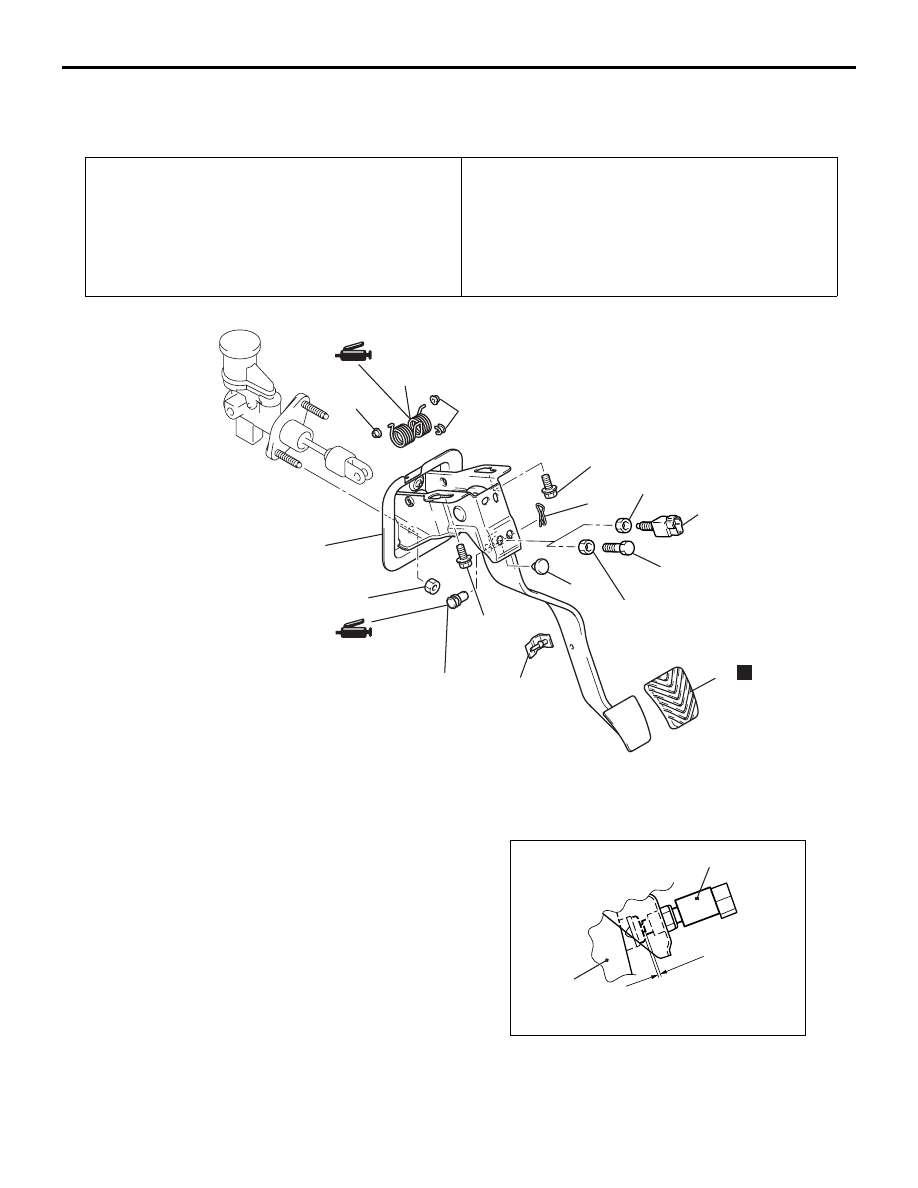

AC900934

7

1

2

3

13 ± 2 N·m

AB

12 ± 2 N·m

9

6

8

12 ± 2 N·m

10

7

13 ± 2 N·m

13 ± 2 N·m

4

5

<Vehicles with

cruise control>

<Vehicles without

cruise control>

N

Removal steps

1.

Snap pin

2.

Clevis pin

3.

Clutch pedal assembly

4.

Adjusting bolt <Vehicles without

cruise control>

>>

A

<<

5.

Clutch switch <Vehicles with cruise

control>

6.

Return spring

7.

Bushing

8.

Stopper

9.

Pedal stopper

10. Pedal pad

INSTALLATION SERVICE POINT

>>A<< CLUTCH SWITCH <VEHICLES WITH

CRUISE CONTROL> INSTALLATION

AC309757

AC

Clutch pedal

Clutch switch

0.5 – 1.0 mm

Install the clutch switch at the specified dimension

when the clutch pedal is released.