Mitsubishi L200. Manual - part 219

CHARGING SYSTEM

ENGINE ELECTRICAL

16-6

ON-VEHICLE SERVICE

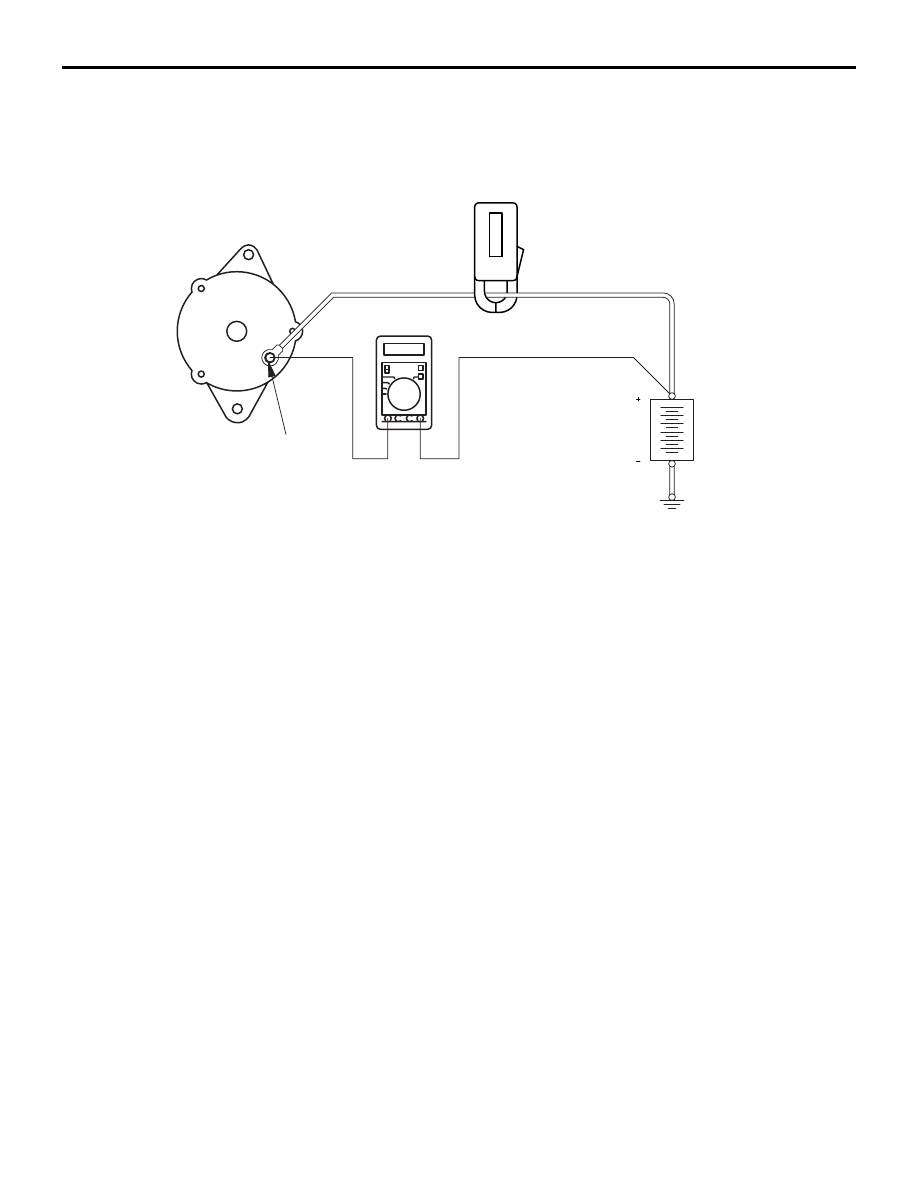

ALTERNATOR OUTPUT LINE VOLTAGE DROP TEST

M1161000900926

AK203361AD

Alternator

Ammeter (clamp-type)

Voltmeter (digital-type)

"B" terminal

Battery

This test determines whether the wiring from the

alternator "B" terminal to the battery (+) terminal

(including the fusible line) is in a good condition or

not.

1. Always be sure to check the following before the

test.

• Alternator installation

• Drive belt tension

(Refer to GROUP 11A

− On-Vehicle Service − Alter-

nator and Power Steering Oil Pump Drive Belt

Tension Check and Adjustment ).

• Fusible link

• Abnormal noise from the alternator while the

engine is running

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

− 100 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and connect the (

−) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect the M.U.T.-III or tachometer

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: Maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is maxi-

mum 0.4 V.