Mitsubishi L200. Manual - part 201

FUEL INJECTOR

DIESEL FUEL

13A-600

REMOVAL SERVICE POINT

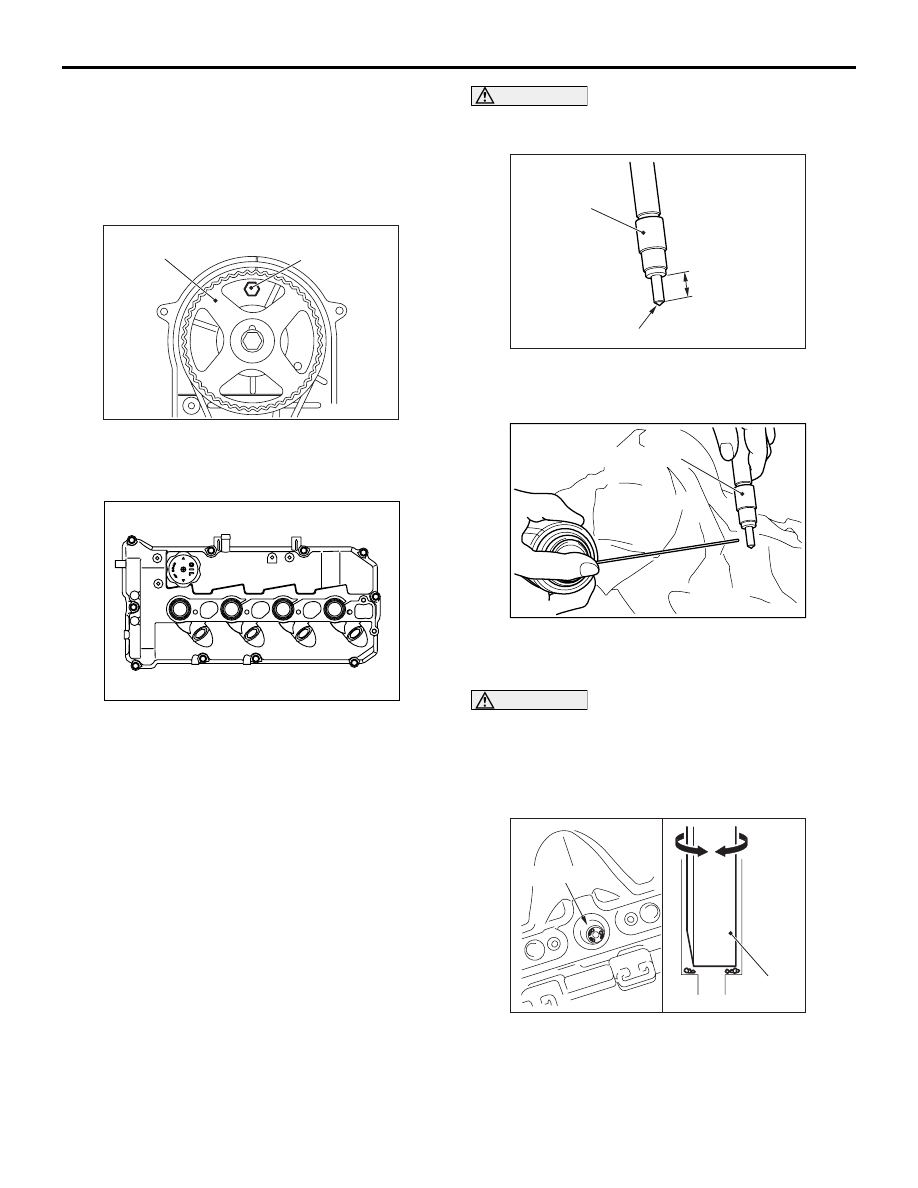

<<A>> ROCKER COVER ASSEMBLY REMOVAL

1. Turn the crankshaft clockwise, and remove the

timing belt rear cover mounting bolts shown in the

figure from the gap of the camshaft sprocket.

2. In the order shown in the figure, loosen the rocker

cover assembly mounting bolts, and then remove

the rocker cover assembly.

INSTALLATION SERVICE POINTS

>>A<< NOZZLE GASKET/FUEL INJECTOR/PIVOT

BOSS/INJECTOR SUPPORTER/INJECTOR

HOLDER BOLT/FUEL LEAK-OFF GASKET/FUEL

LEAKAGE PIPE/EYE BOLT INSTALLATION

1. Clean the fuel injector assembly (nozzle) and the

cylinder head (fuel injector insertion hole) by

following the procedure below.

CAUTION

Do not clean the injection part of the nozzle with

a resin spatula.

(1) Using a resin spatula, scrape off the carbon

deposit on the fuel injector nozzle side face

("A" shown in the figure).

(2) Spray the carburetor cleaner (MZ100139) or

equivalent to the nozzle side face ("A" shown

in the figure).

CAUTION

Do not touch the injection part of the nozzle with

hand or wipe it with a rag.

(3) Leave the injection part for a while until the

carbon deposit melts down, and then blow air

to the injection part.

(4) Insert special tool ornament remover

(MB990784) to the cylinder head (fuel injector

insertion hole) with turning the special tool as

shown, and scrape off the carbon deposit.

>>

A

<< 18. Pivot boss

>>

A

<< 19. Fuel injector

>>

A

<< 20. Nozzle gasket

Removal steps (Continued)

AC502870AB

Timing belt rear cover

mounting bolt

Camshaft sprocket

AC502871

3

AB

1

2

4

5

6

7

8

9

10

AC900270 AB

Fuel injector

A: Nozzle side face

Injection part of the nozzle

AC900203

Fuel injector

AB

AC900204

MB990784

Cylinder head

AB