Mitsubishi L200. Manual - part 155

TROUBLESHOOTING

DIESEL FUEL

13A-416

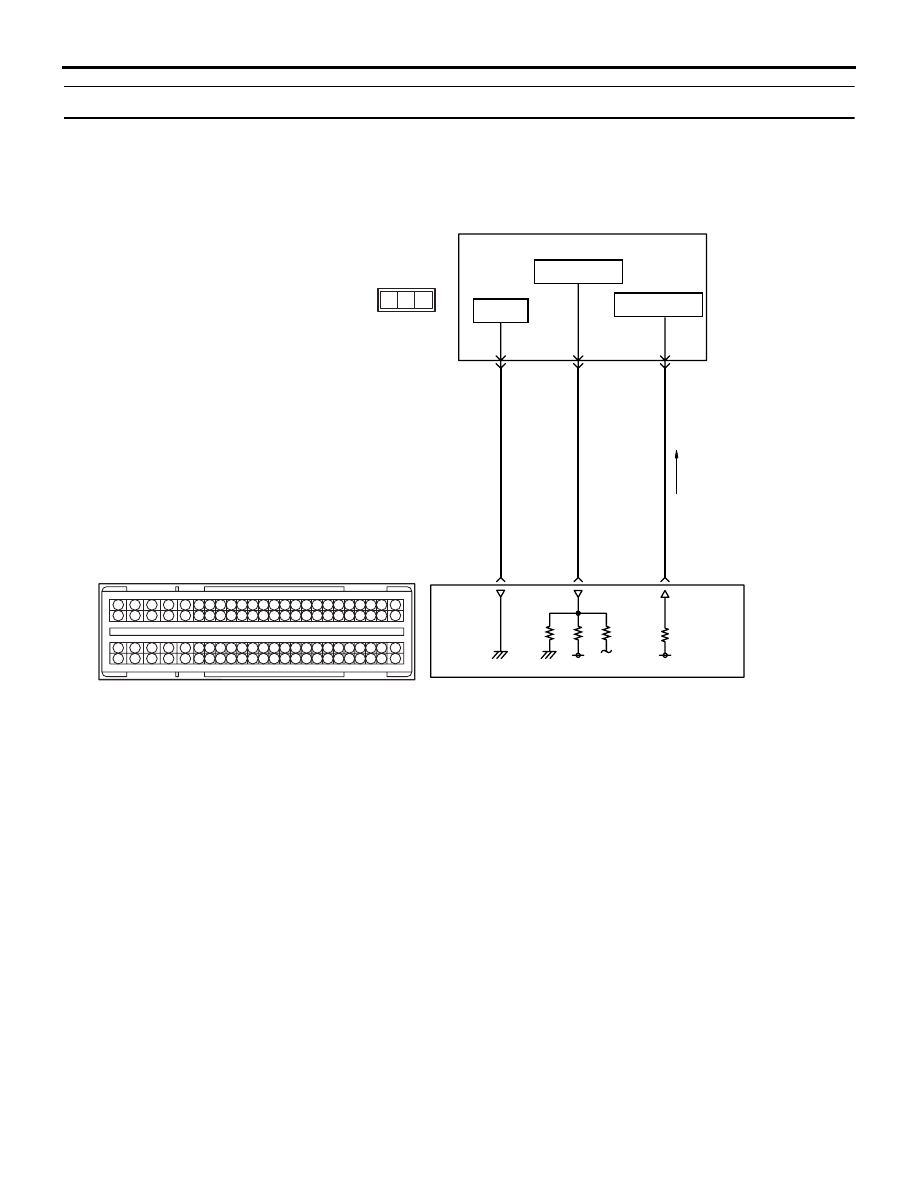

Code No. P2455: Exhaust Differential Pressure Sensor Circuit High Input <Euro5>

OPERATION

• A power voltage of 5 V is applied to the exhaust

differential pressure sensor power terminal (ter-

minal No. 3) from the engine-ECU (terminal No.

94) and earthed to the engine-ECU (terminal No.

80) from the exhaust differential pressure sensor

(terminal No. 2).

• The sensor signal is inputted to the engine-ECU

(terminal No. 56) from the exhaust differential

pressure sensor output terminal (terminal No. 1).

FUNCTION

• The exhaust differential pressure sensor outputs

the voltage to the engine-ECU in accordance with

the difference in the voltage between the DPF

upstream area and the DPF down stream area.

• The engine-ECU anticipates the amount of PM

accumulated in the DPF through this output volt-

age.

TROUBLE JUDGMENT

Check Conditions

• Battery positive voltage is 8 − 16 V

• 2 seconds later after the ignition switch has been

in "ON" position or the engine has started up

Judgment Criterion

• The exhaust differential pressure sensor output

voltage is 4.79 V or more.

PROBABLE CAUSES

• Failed exhaust differential pressure sensor

• Open circuit in exhaust differential pressure sen-

sor circuit or loose connector contact

• Failed engine-ECU

AKB00280

1

2

3

4

5 6 7 8 9

10 1112 13 14 15 16 17 18 19 20 21 22 23 24

25 26

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72

43 44 45 46 47 48

73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96

1 2 3

AB

80

GR-B

P-G

B-O

56

94

A-148

Exhaust differential

pressure sensor

2

1

3

Exhaust Differential Pressure Sensor Circuit

C-105

5 V

Earth

Output signal

Power source

Wire colour code

B: Black LG: Light green G: Green L: Blue W: White Y: Yellow SB: Sky blue BR: Brown O: Orange GR: Grey

R: Red P: Pink V: Violet PU: Purple SI: Silver