Mitsubishi L200. Manual - part 98

TROUBLESHOOTING

DIESEL FUEL

13A-188

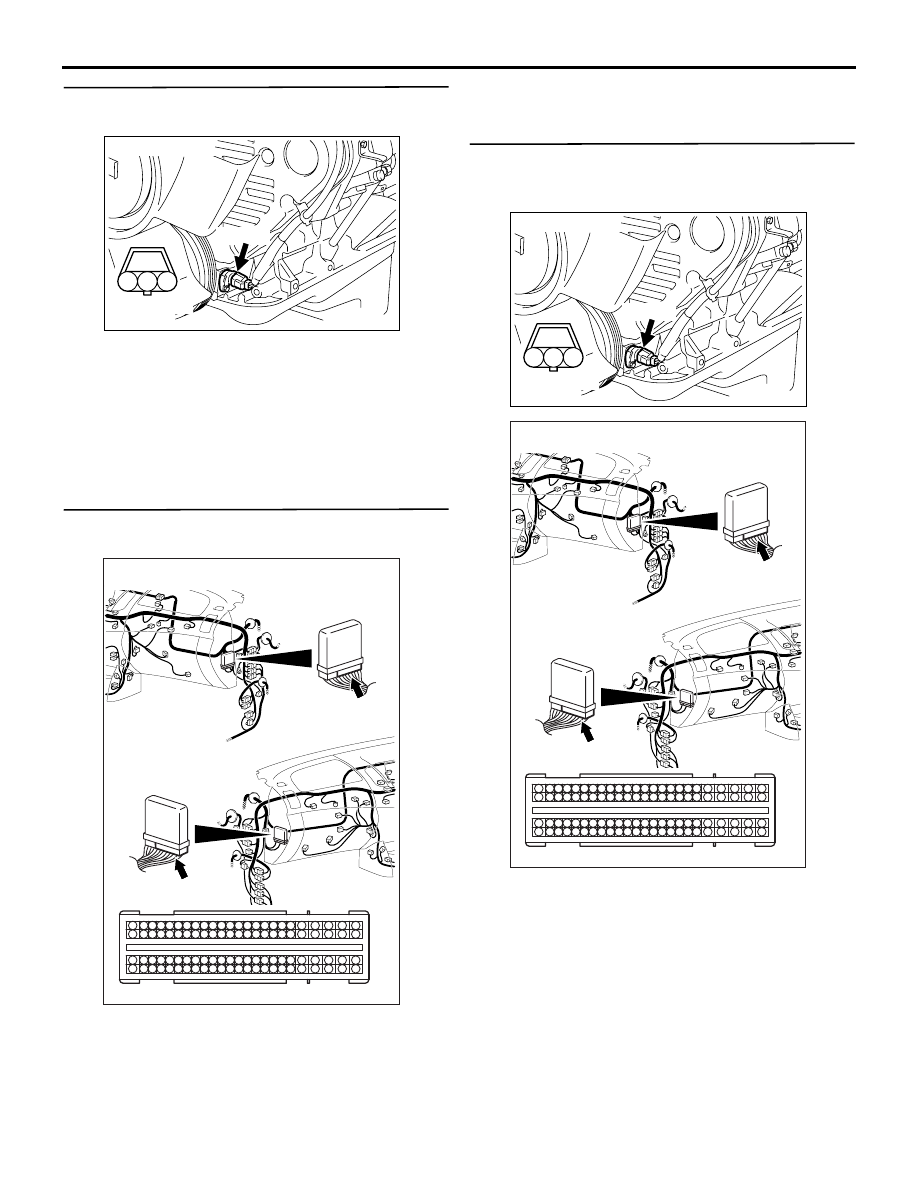

STEP 11. Perform resistance measurement at A-

07 crank angle sensor connector.

• Disconnect connector, and measure at harness

side.

• Resistance between terminal No. 1 and earth.

OK: Continuity (2

Ω or less)

Q: Is the check result normal?

YES :

Go to Step 14 .

NO :

Go to Step 12 .

STEP 12. Connector check: C-105 engine-ECU

connector

Q: Is the check result normal?

YES :

Go to Step 13 .

NO :

Repair or replace the connector.

STEP 13. Check harness between A-07 (terminal

No. 1) crank angle sensor connector and C-105

(terminal No. 91) engine-ECU connector.

NOTE: Before checking harness, check intermediate

connector A-133, and repair if necessary.

• Check earthing line for open circuit and damage.

Q: Is the check result normal?

YES :

Go to Step 8 .

NO :

Repair the damaged harness wire.

AK501329

1

2

3

AB

Harness side

connector

A-07 (B)

Connector: A-07

AKA00089

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

43

44

45

46

47

48

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

C-105 (B)

C-105 (B)

<R.H. drive vehicles>

Harness side connector

<L.H. drive vehicles>

Connector: C-105

AB

AK501329

1

2

3

AB

Harness side

connector

A-07 (B)

Connector: A-07

AKA00089

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

43

44

45

46

47

48

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

C-105 (B)

C-105 (B)

<R.H. drive vehicles>

Harness side connector

<L.H. drive vehicles>

Connector: C-105

AB