Mitsubishi L200. Manual - part 67

TROUBLESHOOTING

DIESEL FUEL

13A-64

• Failed rail pressure sensor.

• Harness damage in rail pressure sensor circuit or

loose connector contact.

• Failed engine-ECU

DIAGNOSTIC PROCEDURE

STEP 1. M.U.T.-III diagnosis code

Q: Is any other diagnosis code than P0093 set?

YES :

Inspection chart for diagnosis codes (Refer

to

NO :

Go to Step 2 .

STEP 2. Detection of fuel line leakage

• Check whether fuel is leaking from a high-pres-

sure fuel line.

Q: Is the check result normal?

YES :

Go to Step 3 .

NO :

Replace the parts of an abnormal location.

STEP 3. Release the air from the fuel line.

• After releasing the air from the fuel line, continue

idle operation for about five minutes and recheck

for trouble symptoms.

Q: Does the trouble symptom persist?

YES :

Go to Step 4 .

NO :

The check is end.

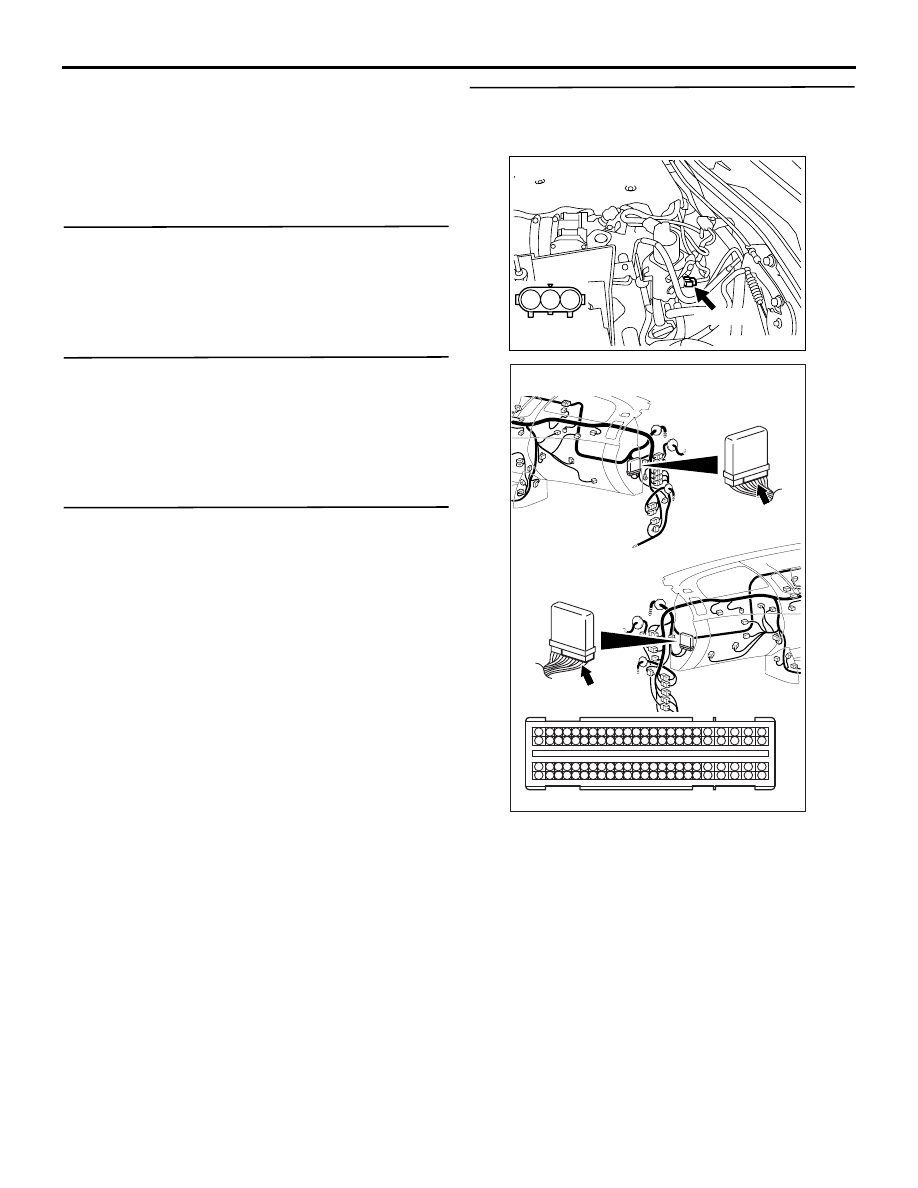

STEP 4. Connector check: A-44 rail pressure

sensor connector and C-105 engine-ECU

connector.

Q: Are the check results normal?

YES :

Go to Step 5 .

NO :

Repair or replace the connector.

AK501327

1

2

3

AB

A-44 (B)

Harness side

connector

Connector: A-44

AKA00089

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

43

44

45

46

47

48

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

C-105 (B)

C-105 (B)

<R.H. drive vehicles>

Harness side connector

<L.H. drive vehicles>

Connector: C-105

AB