Mitsubishi L200. Manual - part 55

TROUBLESHOOTING

DIESEL FUEL

13A-16

NOTE:

.

•

After the engine-ECU has detected a malfunction, the engine warning lamp illuminates when the engine is

next turned on and the same malfunction is re-detected. However, for items marked with a "*" in the diag-

nosis code number column, the engine warning lamp illuminates only on the first detection of the malfunc-

tion.

•

When the fuel runs out, the engine warning lamp would illuminate possibly. Supplying the fuel turns off the

engine warning lamp, but the diagnosis code No. P1272 and P1273 are stored.

METHOD OF READING AND ERASING

DIAGNOSIS CODES

Refer to , GROUP 00

− How to Use Troubleshooting/

Inspection Service Points

− How to Cope with Inter-

mittent Malfunctions.

INSPECTION USING M.U.T.-III DATA LIST

AND ACTUATOR TESTING

1. Carry out inspection by means of the data list and

the actuator test function, if there is an

abnormality, check and repair the chassis harness

and components.

2. After repairing, re-check using the M.U.T.-III and

check that the abnormal input and output have

returned to normal as a result of the repairs.

3. Erase the diagnosis code memory.

4. Remove the M.U.T.-III, and then start the engine

again and carry out a road test to confirm that the

problem has disappeared.

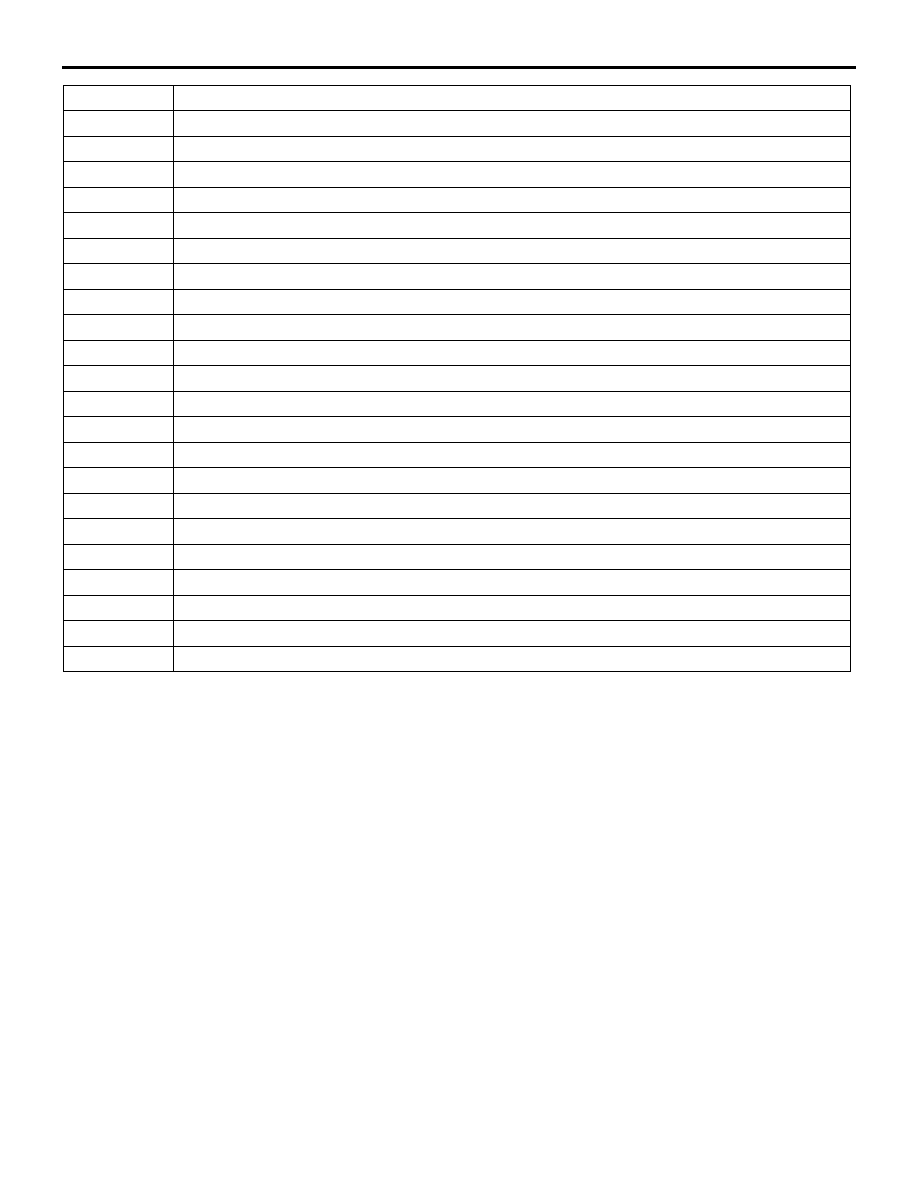

P1498*

Excessive PM accumulated in DPF <Euro5>

P1499*

Abnormally high DPF temperature <Euro5>

P1608*

Battery current sensor system <Euro5>

P1625*

Injection quantity compensation valve error

P1626*

Injection quantity compensation valve not coding

P2118

Throttle valve control (DC motor) current malfunction

P2122*

Accelerator pedal position sensor (main) circuit low input

P2123*

Accelerator pedal position sensor (main) circuit high input

P2127*

Accelerator pedal position sensor (sub) circuit low input

P2128*

Accelerator pedal position sensor (sub) circuit high input

P2138*

Accelerator pedal position sensor (main and sub) range/performance problem

P2146*

Injector common 1 (cylinder No. 1 and No. 4) circuit open

P2147*

Injector common circuit earth short

P2148*

Injector common circuit battery short

P2149*

Injector common 2 (cylinder No. 2 and No. 3) circuit open

P2150*

Injector common 2 circuit earth short <Euro5>

P2151*

Injector common 2 circuit battery short <Euro5>

P2228

Barometric pressure sensor circuit low input

P2229

Barometric pressure sensor circuit high input

P2413

EGR system performance

P2454*

Exhaust differential pressure sensor circuit low input <Euro5>

P2455*

Exhaust differential pressure sensor circuit high input <Euro5>

Code No.

Diagnosis item