Mitsubishi L200. Manual - part 23

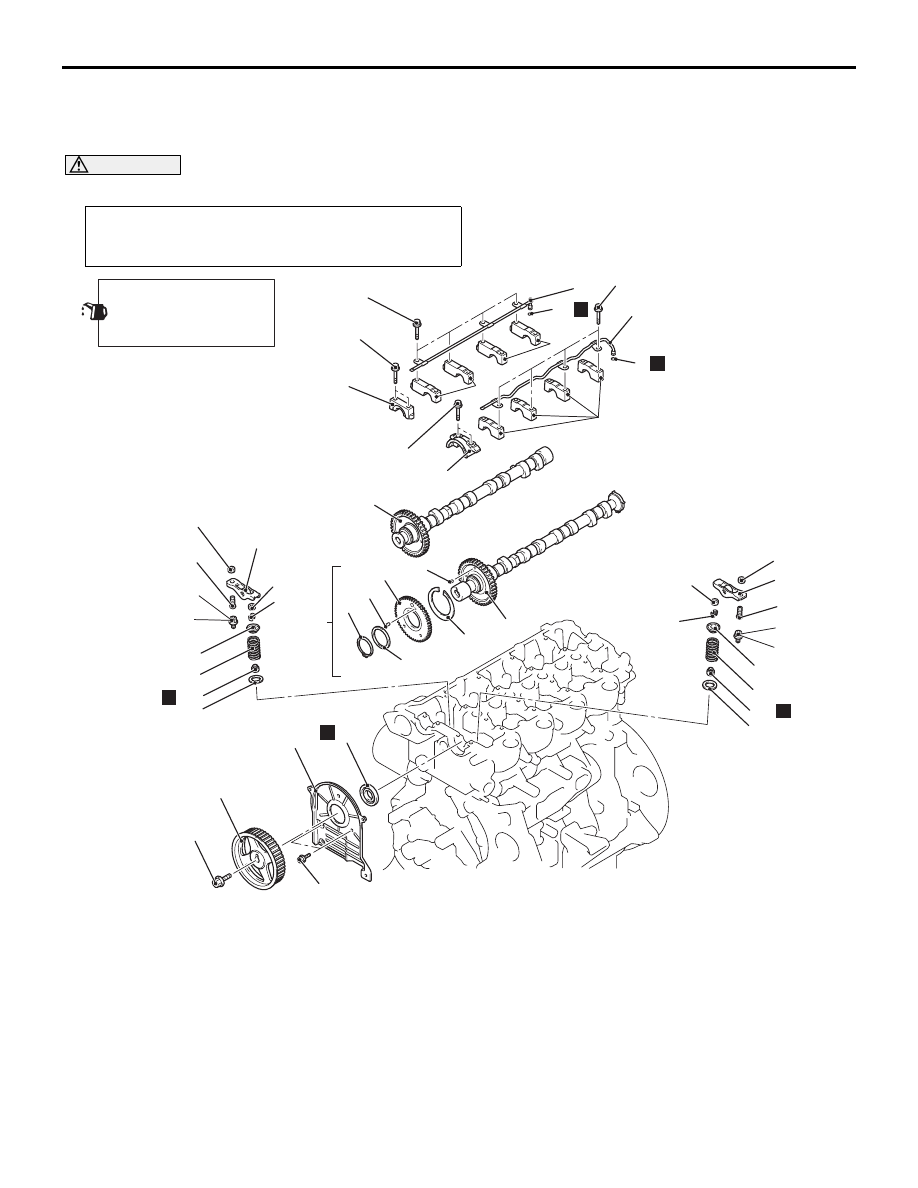

CAMSHAFT AND VALVE STEM SEAL

ENGINE MECHANICAL

11A-20

CAMSHAFT AND VALVE STEM SEAL

REMOVAL AND INSTALLATION

M1112006602262

CAUTION

* Remove and assemble the marked parts in each cylinder unit.

Pre-removal and Post-installation Operation

• Inlet Manifold Removal and Installation (Refer to GROUP

15

− Inlet Manifold

AC501908AD

2

1

18 ± 2 N·m

3

N

4

5

6

N

7

9

7

10

11

12

13

13

14

15

16

17

N

18

18

19

20

21

22

23

24

25*

25*

26*

28

27*

29*

N

26*

27*

29*

28

N

24

20

21

22

23

88 ± 10 N·m

10 ± 2 N·m

20 ± 1 N·m

18 ± 2 N·m

20 ± 1 N·m

11 ± 1 N·m

11 ± 1 N·m

8

Apply engine oil to all

moving parts before

installation.

Inlet camshaft removal steps

•

Timing belt (Refer to

•

Rocker cover (Refer to GROUP

13A

− Fuel Injector

•

Valve clearance check and

adjustment (Refer to

<<

A

>>

>>

K

<<

1.

Camshaft sprocket

2.

Timing belt rear cover

>>

J

<<

3.

Camshaft oil seal

<<

B

>>

>>

I

<<

4.

Front left camshaft bearing cap

>>

I

<<

5.

Inlet oil pipe assembly

>>

I

<<

6.

O-ring

<<

B

>>

>>

I

<<

7.

Left camshaft bearing cap

>>

H

8.

Inlet camshaft assembly

>>

G

<<

9.

Snap ring

>>

G

<<

10. Wave washer

>>

G

<<

11. Sub gear

>>

G

<<

12. C-spring

>>

G

<<

13. Dowel pin

>>

G

<<

14. Inlet camshaft

Inlet camshaft removal steps