Mazda Transaxle G35M–R. Manual - part 8

MANUAL TRANSAXLE

J–13

J

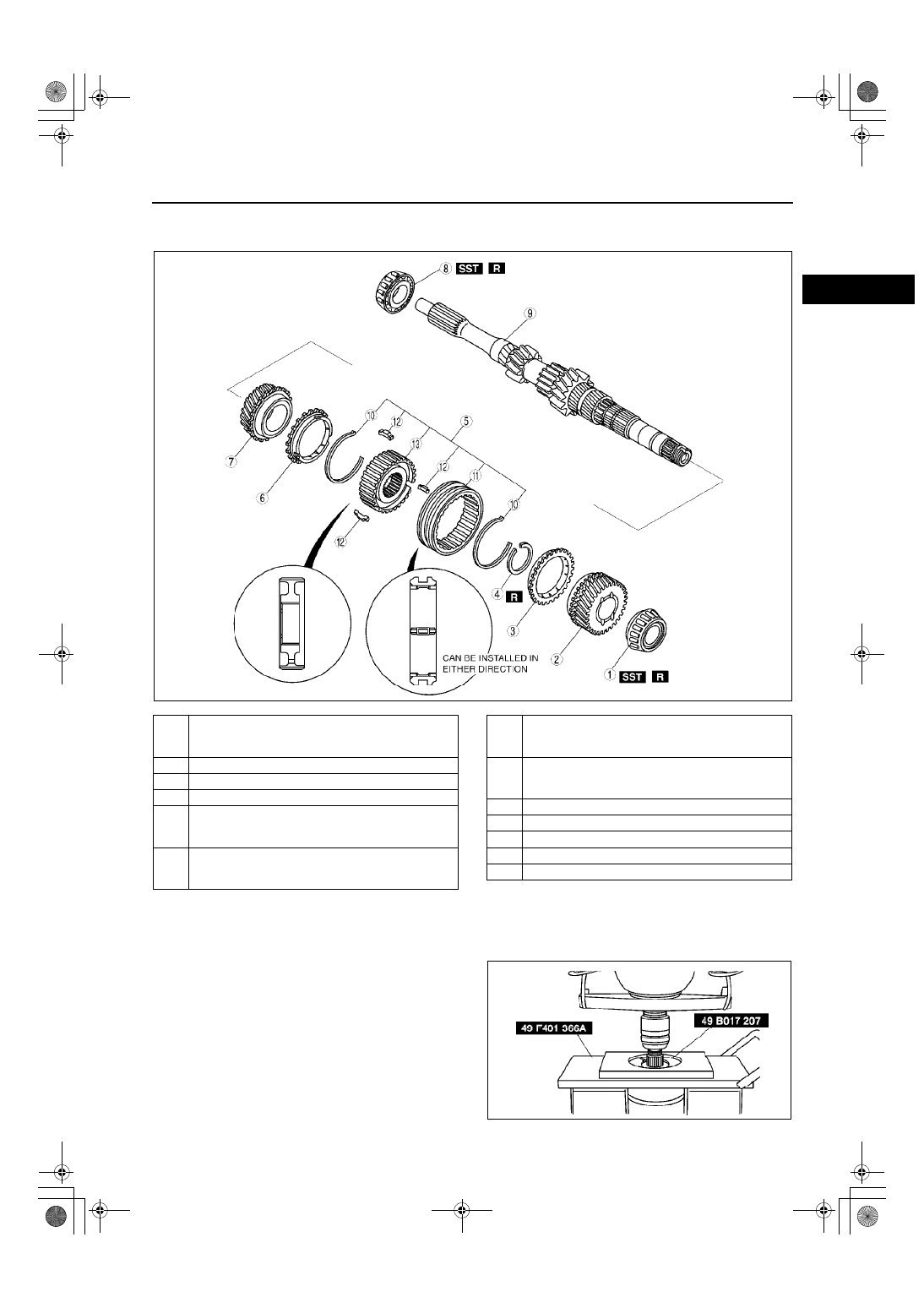

PRIMARY SHAFT COMPONENTS DISASSEMBLY

A6E511217201M02

1. Disassemble in the order shown in the figure.

.

Bearing (4th Gear End) Disassembly Note

1. Remove the bearing using the SST.

Z4F5112M023

1

Bearing (4th gear end)

(See

J–13 Bearing (4th Gear End) Disassembly

2

4th gear

3

4th synchronizer ring

4

Retaining ring

5

3rd/4th clutch hub component

(See

J–14 3rd/4th Clutch Hub Component, 3rd

Synchronizer Ring and 3rd Gear Disassembly Note

6

3rd synchronizer ring

(See

J–14 3rd/4th Clutch Hub Component, 3rd

Synchronizer Ring and 3rd Gear Disassembly Note

7

3rd gear

(See

J–14 3rd/4th Clutch Hub Component, 3rd

Synchronizer Ring and 3rd Gear Disassembly Note

8

Bearing (primary shaft end)

(See

J–14 Bearing (Primary Shaft End)

9

Primary shaft gear

10

Synchronizer key springs

11

3rd/4th clutch hub sleeve

12

Synchronizer keys

13

3rd/4th clutch hub

Z4F5112M024