Mazda Transaxle G35M–R. Manual - part 6

MANUAL TRANSAXLE

J–5

J

Locknut Disassembly Note

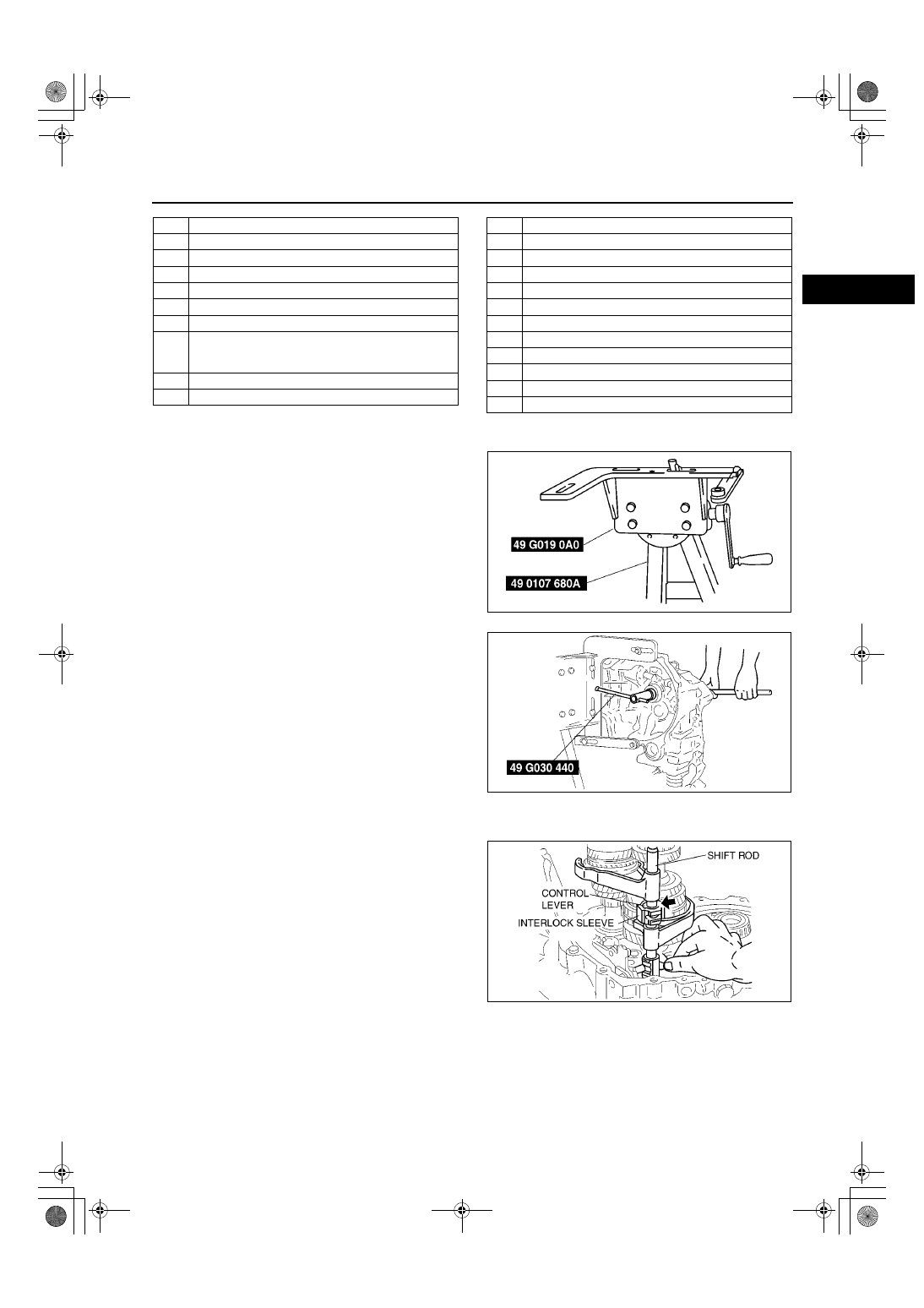

1. Assemble the SST.

2. Lift the transaxle and mount it on the SST.

3. Lock the primary shaft with the SST.

4. Shift to 1st gear to lock the rotation of the primary

shaft.

5. Bend back the caulking of locknuts using a chisel.

6. Remove the locknuts from the primary and

secondary shafts.

Shift Fork and Shift Rod Component Disassembly Note

1. Aligh the ends of the interlock sleeve and of the

control lever (arrow). Turn the shift rod

counterclockwise.

2. While holding the 1st/2nd shift fork with one hand

and the 3rd/4th shift fork with the other, raise

them both at the same time and shift each of the

clutch hub sleeves.

17

Reverse idler shaft

18

Reverse idler gear

19

5th/reverse shift rod

20

5th/reverse shift rod end

21

Pin

22

Crank lever shaft

23

Crank lever component

24

Shift fork and shift rod component

(See

J–5 Shift Fork and Shift Rod Component

)

25

Push pin

26

Primary shaft gear component

27

Secondary shaft gear component

28

Differential component

29

Clutch housing

30

Synchronizer key springs

31

Clutch hub sleeve

32

Clutch hub

33

3rd/4th shift fork

34

Interlock sleeve

35

Control lever

36

1st/2nd shift fork

37

Control end

38

Control rod

A6E5112M108

Z4F5112M004

Z4F5112M005