Mazda Automatic Transaxle JA5A-EL. Manual - part 29

AUTOMATIC TRANSAXLE

K121

K1

1. Verify that there is no air leakage when applying compressed air through the oil hole opposite the return spring.

2. Verify that there is airflow when applying

compressed air through the oil hole on the return

spring side.

• Replace the coasting clutch piston if it is

damaged or malfunctioning.

Air pressure

390 kPa {4.0 kgf/cm

2

, 57 psi} max.

End Of Sie

REVERSE CLUTCH AND HIGH CLUTCH ASSEMBLY

AME571419500A04

Assembly Procedure

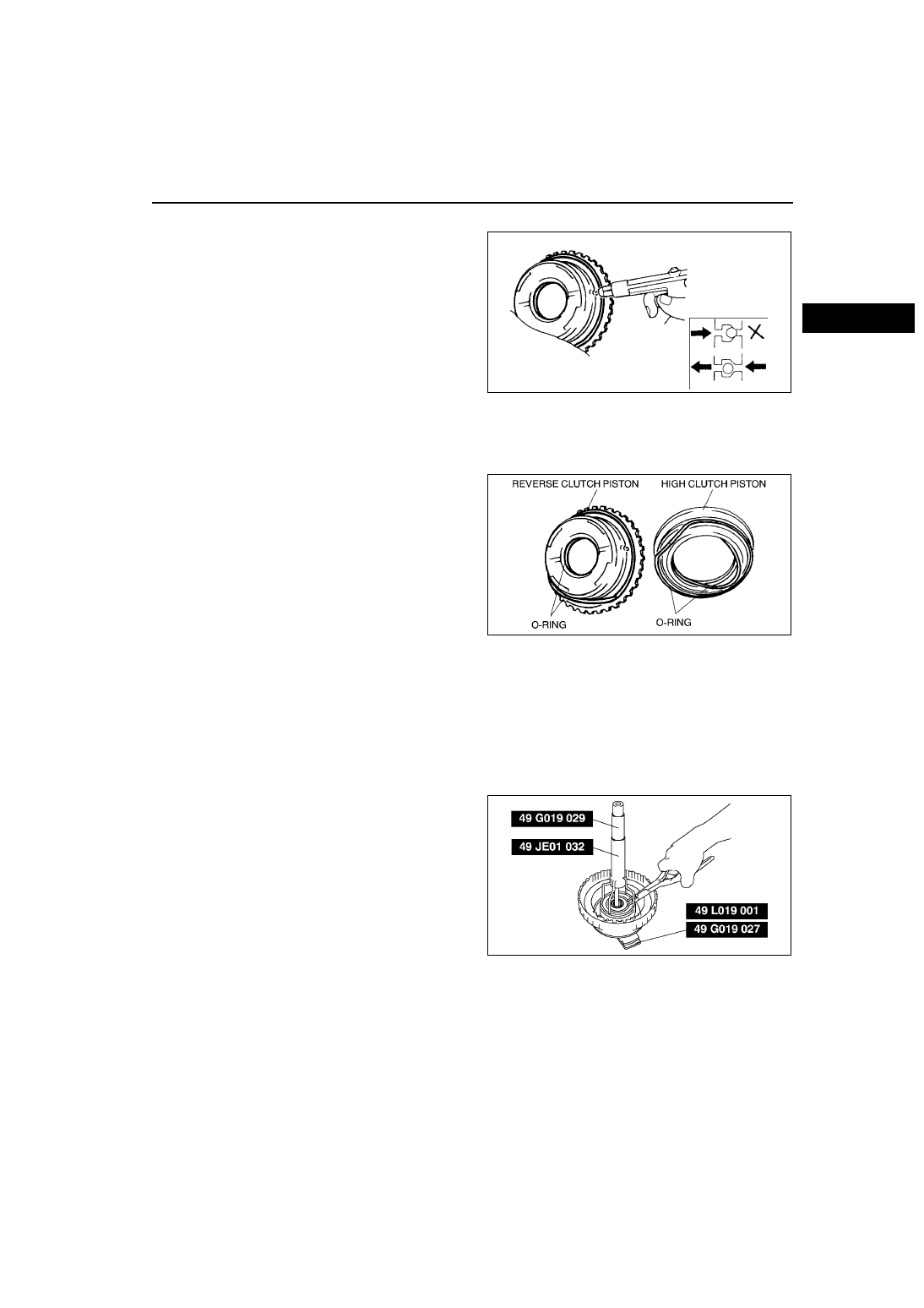

1. Apply a coat of ATF to new O-rings, then install

them to reverse and high clutch pistons.

2. Apply a coat of ATF to inside of reverse clutch

piston, then install the high clutch piston into the

reverse clutch piston while rotating the piston by

hand.

3. Apply a coat of ATF to inside of drum, then install

the reverse clutch piston into drum while rotating

the piston by hand.

Note

• After installing required parts to the piston,

ensure that the piston rotates smoothly by

hand. If not, the O-ring may be caught.

4. Install the return spring.

5. Install the spring retainer as follows.

(1) Position the spring retainer.

Caution

•••• Depress the spring retainer only enough to remove the snap ring. Overpressing will damage the

retainer component edges.

(2) Install the SSTs in clutch drum as shown.

(3) Install the snap ring.

(4) Remove the SSTs.

Caution

•••• Depress the spring retainer only enough

to install the snap ring. Overpressing will

damage the retainer component edges.

AMU0517A144

AMU0517A058

AMU0517A165