Mazda RX7. Manual - part 20

BRAKE SYSTEM

Article Text (p. 6)

1983 Mazda RX7

For www.iluvmyrx7.com

Copyright © 1998 Mitchell Repair Information Company, LLC

Sunday, August 26, 2001 04:54PM

and dust boot. Place a piece of wood in front of piston.

2) Apply compressed air to fluid inlet and remove piston.

Tap caliper with plastic hammer, if required. Remove piston seal

without damaging caliper bore.

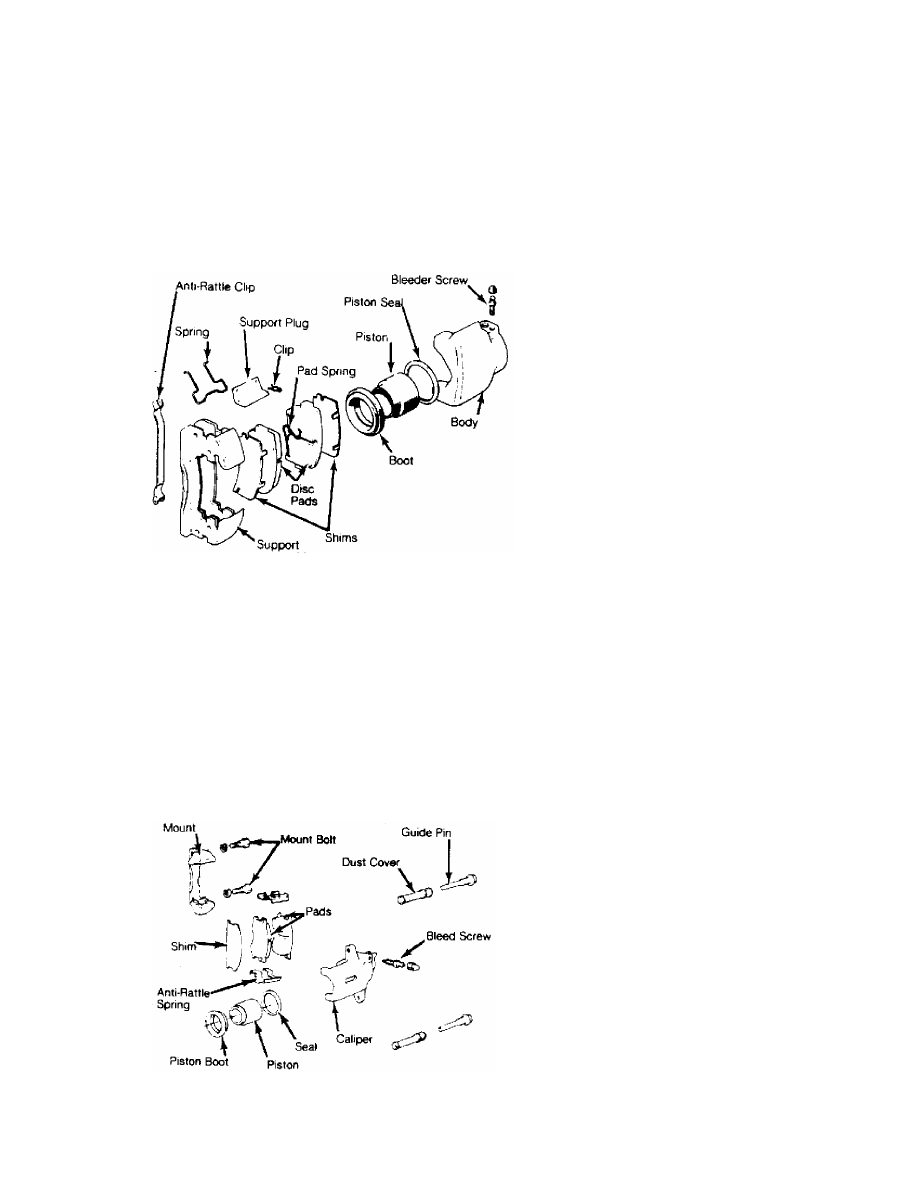

Fig. 3: Exploded View of Pickup Front Disc Brake Caliper

Cleaning & Inspection

1) Wash all parts in alcohol or brake fluid and air dry.

Inspect cylinder bore and piston for scoring, scratches or rust.

Replace defective parts.

2) Minor damage may be removed with crocus cloth. Always

replace dust boot and piston seal when caliper is disassembled.

Reassembly

1) Apply clean brake fluid to cylinder bore, piston and

piston seal. Seat piston seal in caliper bore.

2) Install piston carefully into cylinder bore and install

dust boot and retainer.

Fig. 4: Exploded View of RX7 Front Brake Caliper

REAR DISC BRAKE CALIPER