Mazda CX 7. Manual - part 131

EMISSION SYSTEM [L3 WITH TC]

01-16–9

01-16

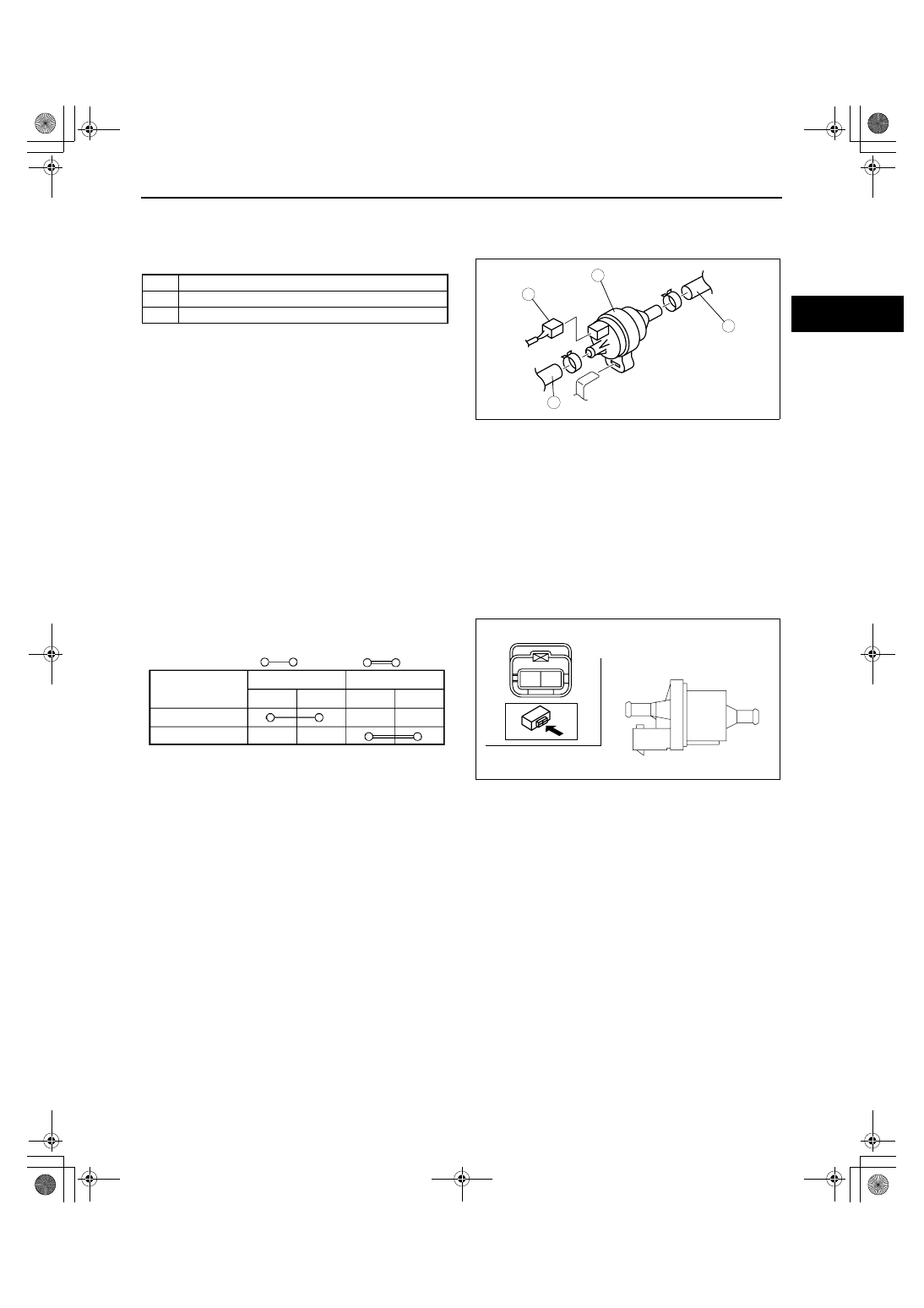

PURGE SOLENOID VALVE REMOVAL/INSTALLATION[L3 WITH TC]

id011639803500

1. Disconnect the negative battery cable.

2. Remove the charge air cooler duct.

3. Remove in the order indicated in the table.

.

4. Install in the reverse order of removal.

End Of Sie

PURGE SOLENOID VALVE INSPECTION[L3 WITH TC]

id011639800900

Airflow Inspection

Note

• Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Remove the purge solenoid valve. (See 01-16-9 PURGE SOLENOID VALVE REMOVAL/INSTALLATION[L3

WITH TC].)

3. Inspect airflow between the ports under the following conditions.

• If not as specified, replace the purge solenoid valve. (See 01-16-9 PURGE SOLENOID VALVE REMOVAL/

INSTALLATION[L3 WITH TC].)

• If as specified, carry out the “Circuit Open/

Short Inspection”.

1

Connector

2

Vacuum hose

3

Purge solenoid valve

3

1

2

2

acxuuw00000217

A

B

A

B

acxuuw00000046

Step

: Continuity

: Airflow

Terminal

Port

B

A

B

A

B+

GND

1

2

acxuuw00000045

1871-1U-06B(01-16).fm 9 ページ 2006年3月15日 水曜日 午前10時48分